Silicon and thin-film photovoltaics

Solar technology comes in many flavors, from rigid silicon to flexible thin-film cells, each tuned to another application field.

Imec has been researching solar technology for over 30 years. Since 2022, photovoltaic research has been performed in the joint research institute imo-imomec, with Hasselt University as a partner.

The focus is on efficiency, reliability, cost-effectiveness and manufacturability of new technologies and concepts, from cell to module and full system.

The application domains are many and go beyond the well-known residential solar panels or solar parks. New kinds of solar cells can be integrated into building facades, cars, or greenhouses. They can also be applied on water as floating PV or in space for spacecraft, satellites etc.

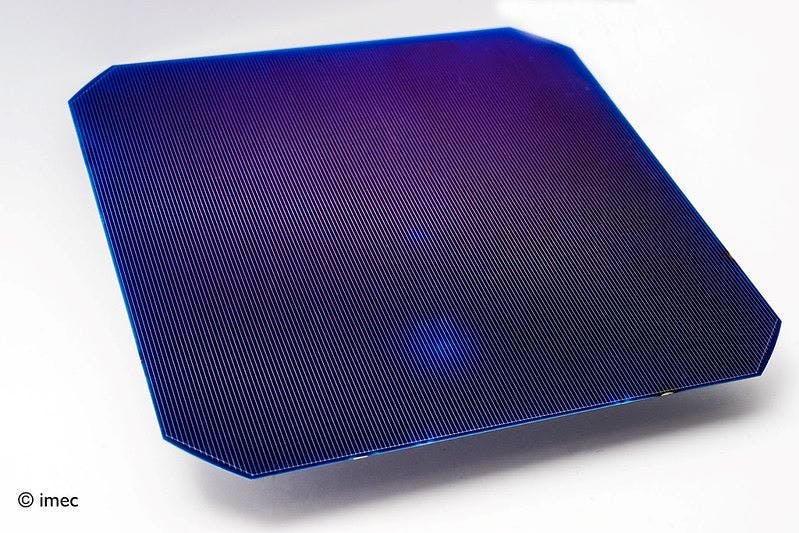

Wafer-based silicon PV

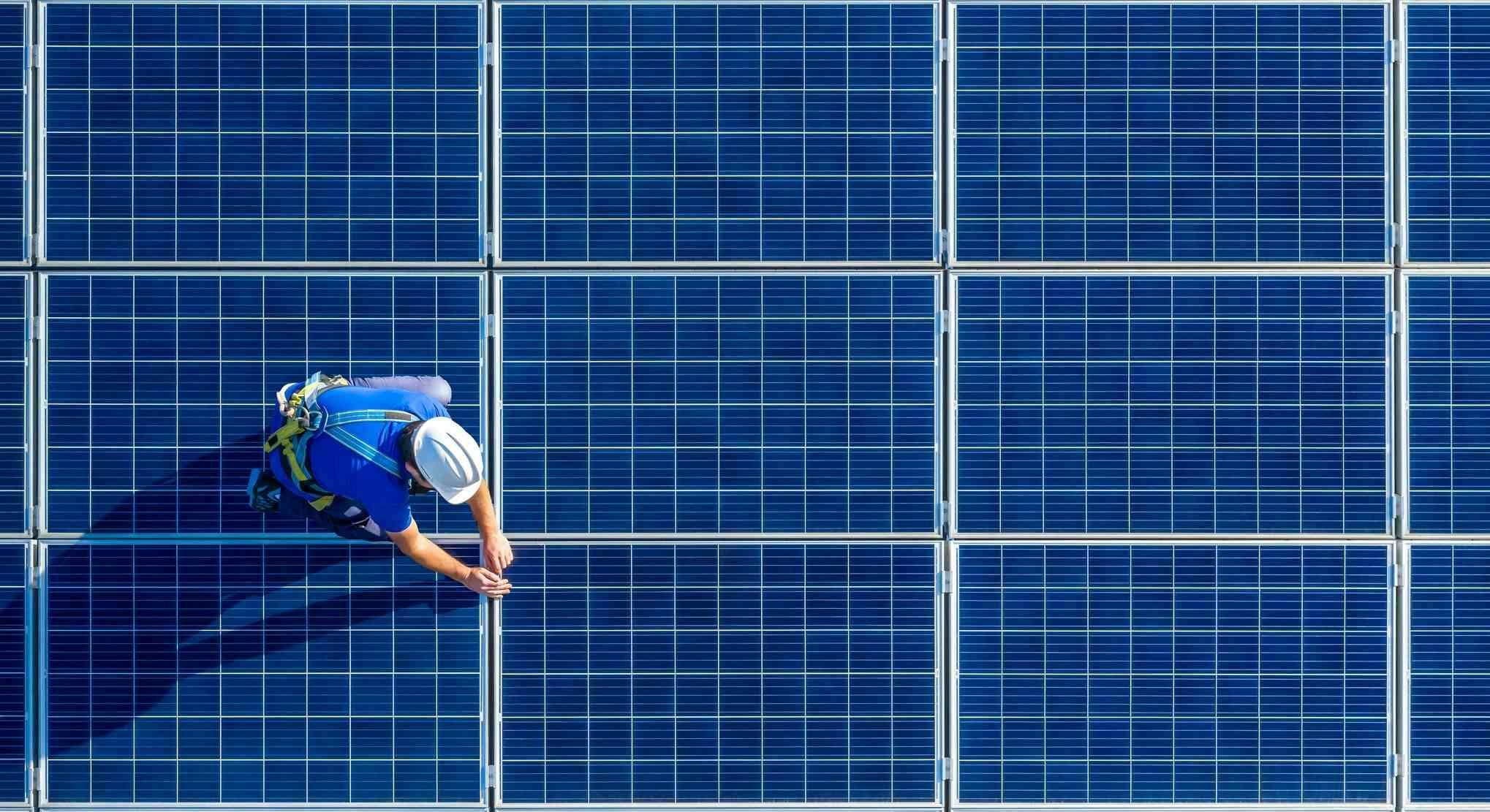

Wafer-based silicon PV technology is one of the most mature and widely adopted technologies in the solar industry. The technology is a proven choice when reliability, efficiency, and scalability are important.

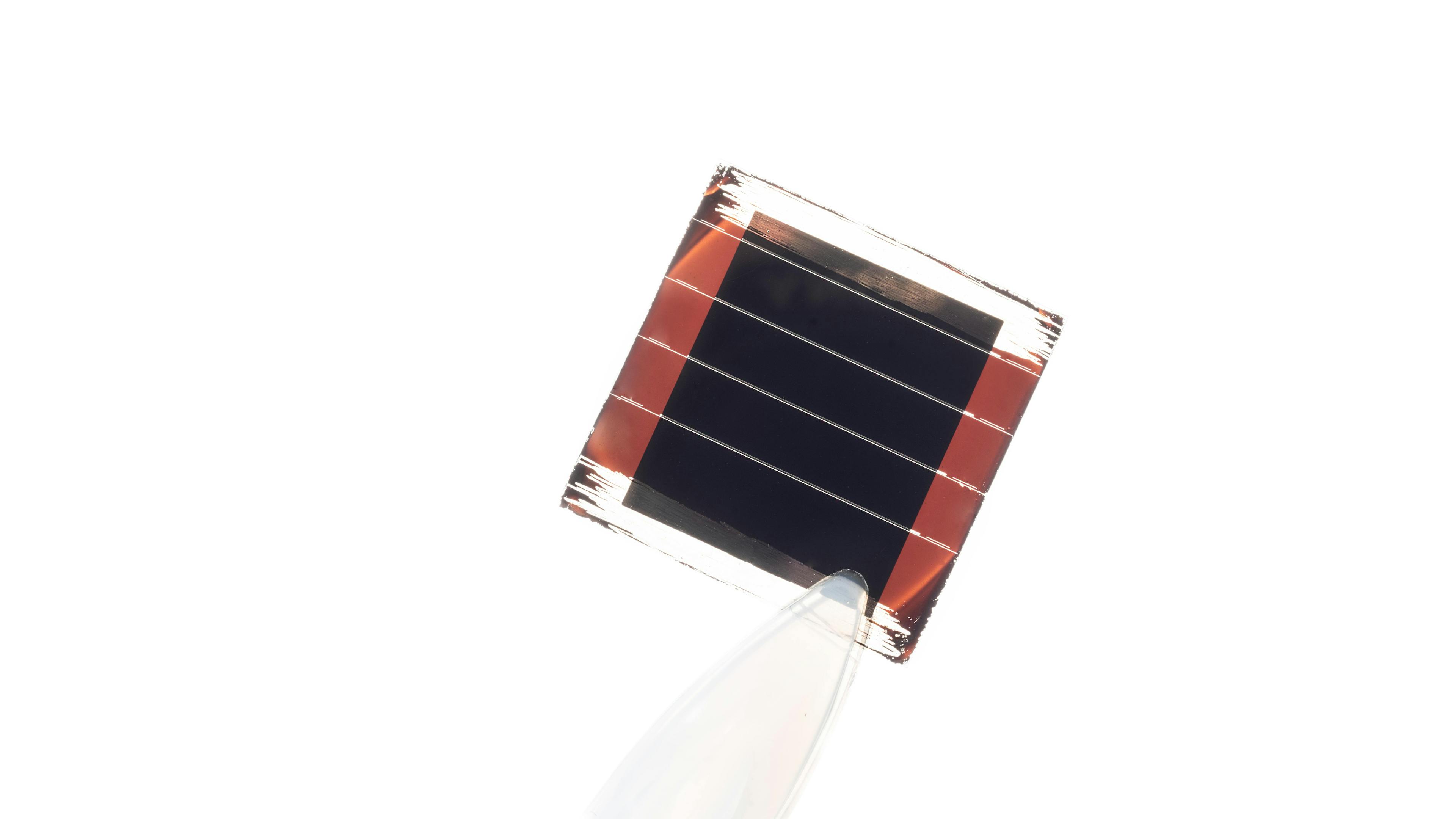

Mono- or polycrystalline silicon wafers are used to build these solar cells with processes such as doping, passivation and the application of metal contacts. Hereafter, they are assembled into larger modules or panels.

Imec researches this type of solar technology to:

- Further improve its energy conversion efficiency.

- Reduce the manufacturing cost.

- Innovate the metallization schemes to reduce material use.

- Develop new interconnection concepts (2-sided, back-sided, shingled).

- Create different module alternatives (glass-glass, lightweight laminates, curved).

- Integrate in new structures and applications.

This type of solar cell is typically used in high-efficiency applications like solar parks and rooftops – and even integrated into building skins. But new concepts might enable other applications.

Bifacial solar cell

Thin-film PV

Instead of using thick layers of crystalline silicon (150 to 200µm), thin-film solar cells utilize thin ~1µm high-absorbent semiconductor layers to convert sunlight into electricity. Also, modules are not made by interconnecting small cells but instead by growing thin layers directly on the substrate (e.g. glass).

Several types of thin-film technologies exist, each with its own set of advantages and disadvantages:

- cadmium telluride (CdTe)

- copper indium gallium selenide (CIGS)

- organic materials

- perovskites

Thin-film PV is used in applications where flexibility, color, light weight and low cost are important, as well as a versatile form factor and transparency. Think of integrated PV in curved structures of buildings or in their windows, in cars, in greenhouses etc.

Window-integrated thin-film PV, with CIGS modules and different colored perovskite minimodules

Extensive research – also by imec – has resulted in a conversion efficiency that approaches the one from the traditional wafer-based silicon solar cells. More specifically, imec focuses on:

- new materials and processes for increased efficiency and lifetime

- upscalable processing techniques

- back-end interconnection technology

- rigid and flexible modules

- non-transparent and transparent modules

Tandem PV

Different types of solar cell technologies can be combined to more efficiently convert a wider range of the light spectrum into electricity. For example, by stacking a highly efficient semi-transparent perovskite top cell on a silicon bottom cell, total energy conversion efficiencies can surpass 30%.

Imec’s research is centered around:

- 2-, 3- and 4-terminal cells

- hybrid perovskite coatings

- sub-micron texturing

- upscaling to large-area modules

Perovskite/silicon tandem solar module

Energy yield modeling

PV panels are used in different ways and under varying conditions and different climates. This makes their performance very different from standard laboratory conditions.

Imec has developed simulation software that accurately predicts the daily energy yield of solar cells and modules under varying and dynamic meteorological and irradiation conditions. This model considers various factors such as solar panel characteristics, environmental conditions, and system configuration to estimate the electricity generation over time.

It’s an excellent tool for:

- rapid assessment of material and technology changes at the cell and module level

- accurate short-term energy yield forecasting for PV power plants and residential solar systems.

- limiting curtailment situations and grid balancing issues, and hence creating more value across the full renewable energy value chain

State-of-the-art lab facilities

All the above PV work is done in the framework of EnergyVille, a collaboration between the Flemish research partners KU Leuven, VITO, imec and UHasselt.

At the EnergyVille premises in Genk, Belgium, there are state-of-the-art facilities for photovoltaic technology development. This infrastructure comprises:

- laboratories for thin-film cell development and solar-cell-to-module processing

- lab facilities for upscaled manufacturing of solar cells and modules

- laboratories for characterizing solar cells and modules

- advanced testing labs to assess the performance and efficiency of photovoltaic devices

Researchers at EnergyVille utilize these facilities to conduct experiments, analyze materials, and develop innovative solutions to advance the field of photovoltaics.

Want to get involved in our research? Click the button below to get in touch.

EnergyVille is a collaboration between the Flemish research partners KU Leuven, VITO, imec and UHasselt in the field of sustainable energy and intelligent energy systems. Our researchers provide expertise to industry and public authorities on energy-efficient buildings and intelligent networks for a sustainable urban environment. This includes, for example, smart grids and advanced district heating and cooling.

Combining forces in research into the next generation, thin film solar cells. Solliance was founded with that goal in 2010. The research organization is a joint venture of ECN, TNO, Holst Centre and imec. Together with the academic partners TU Eindhoven, University of Hasselt, TU Delft and Forschungszentrum Jülich, the research institutes can play a significant role in global research into the solar technology of the future.