Electroplating Lithium – regulating nucleation and early growth through seed layers

Leuven | More than two weeks ago

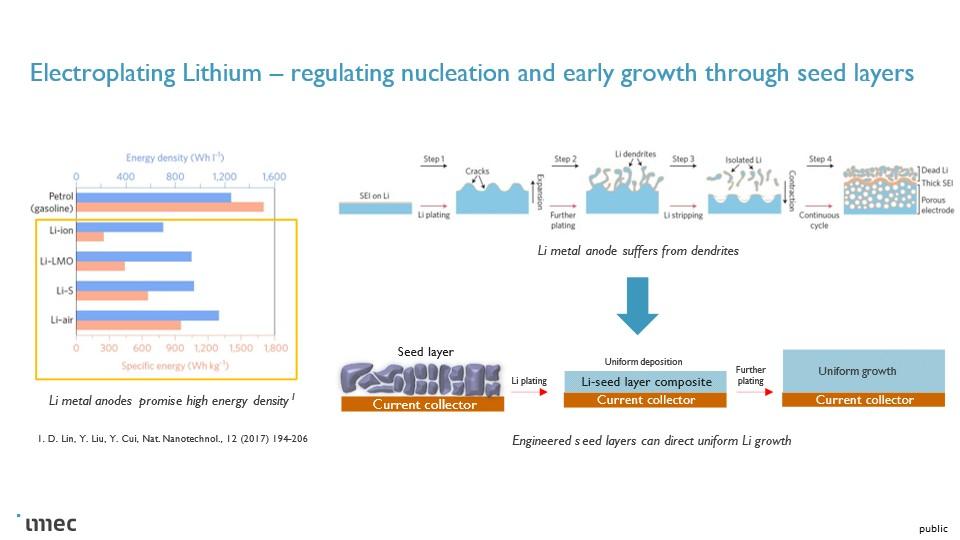

Towards next generation batteries with Li metal anodes

Today, state-of-the art Li-ion cells reach nearly 700 Wh/L and the ambition for next generation batteries targets 1000 Wh/L, which can be realized by Li metal anodes in conjunction with solid-state electrolytes. At the heart of this advanced technology is the process of continuous plating and stripping of lithium during the cycling of the battery. Owing to the highly reactive nature of Li, this is a complicated process with several challenges during both plating (for e.g., dendrite formation and growth, dead lithium, continuous interface change, short circuit etc.) and stripping (void formation, pitting, broken interface layers etc.). Adding to the issue is the choice of commercial current collectors like Copper or Nickel foils, which do not have good adhesion to Lithium metal and hence make it difficult to form Li thin films on their surface. Lithium plating predominantly leads to a non-planar dendritic surface because of several factors. The high surface diffusion barrier for Li (compared to Mg for example) leads to lower diffusivity of the adatom on the surface, and hence higher tendency to form dendrites (compared to Mg). Similarly, interaction energy between two adjacent adatoms of Li is much lower (compared to Mg) and do not readily form stable nucleation centres for smooth thin film growth. One mitigation strategy is to facilitate diffusion of Li during initial growth stages by introducing seed layers. These seed layers can be alloys, oxides or even organic materials that aid in surface diffusion resulting in smooth Li films.

At imec, we are working on different strategies to electroplate smooth Li thin films (0 by introducing various seed layers. This is supplemented by expertise from our thin film platform, enabling us to deposit nanometre thick seed layers of inorganic/organic materials. In this project you will study various seed layers for Li plating focusing on nucleation and early-stage growth. You will work on design principles for seed layers, their fabrication through various routes including PVD, chemical and electrochemical processing etc. and their effect on Li plating/stripping. You will be working in a team together with other PhD students, researchers, and engineers, while collaborating with several different universities, research institutes, and companies. Your efforts will form the basis of successful fabrication of Li – metal batteries which relies on homogeneous and dendrite free Li plating/stripping.

Required background: Chemistry, Materials science, Electrochemistry

Type of work: 80% Experimental, 20% Literature

Supervisor: Philippe Vereecken

Daily advisor: Sai Gourang Patnaik

The reference code for this position is 2024-105. Mention this reference code on your application form.