PCR on chip: accelerated tests on silicon

Faster, more accurate and affordable, ... on-chip PCR is a key component of advanced diagnostic, therapeutic and research lab-on-chip workflows.

The COVID-19 pandemic abundantly demonstrated the importance of fast, accurate and affordable diagnostics. Without it, effective and personalized healthcare is out of reach.

Nanotechnology plays an important role in the development of such next-gen testing platforms. Moving stages of the workflow to a microfluidic chip results in benefits such as miniaturization, automation, and lower use of costly reagents.

Imec’s ultra-fast PCR-on-chip technology is a prime example of that approach.

This article dives into how microfluidics accelerates DNA analysis for infectious disease detection

Advantages of moving PCR to a chip

For many diagnostic, therapeutic and research goals, DNA-based detection remains the gold standard. And DNA amplification is a crucial stage of that process. The go-to technique is polymerase chain reaction (PCR), which relies on cycles of repeated heating and cooling to generate thousands of millions of copies of a specific piece of DNA.

Moving this thermal cycling to tightly controlled microfluidic channels on a chip immediately results in several benefits:

- acceleration of the amplification process, from hours to minutes

- cost reduction, because of the lower volume of reagent fluid

- increased accuracy, due to automation of the process

Finally, PCR-on-chip technology opens the door to digital droplet PCR (ddPCR), a method for quantifying molecules of interest without need for calibration.

Imec’s PCR technology

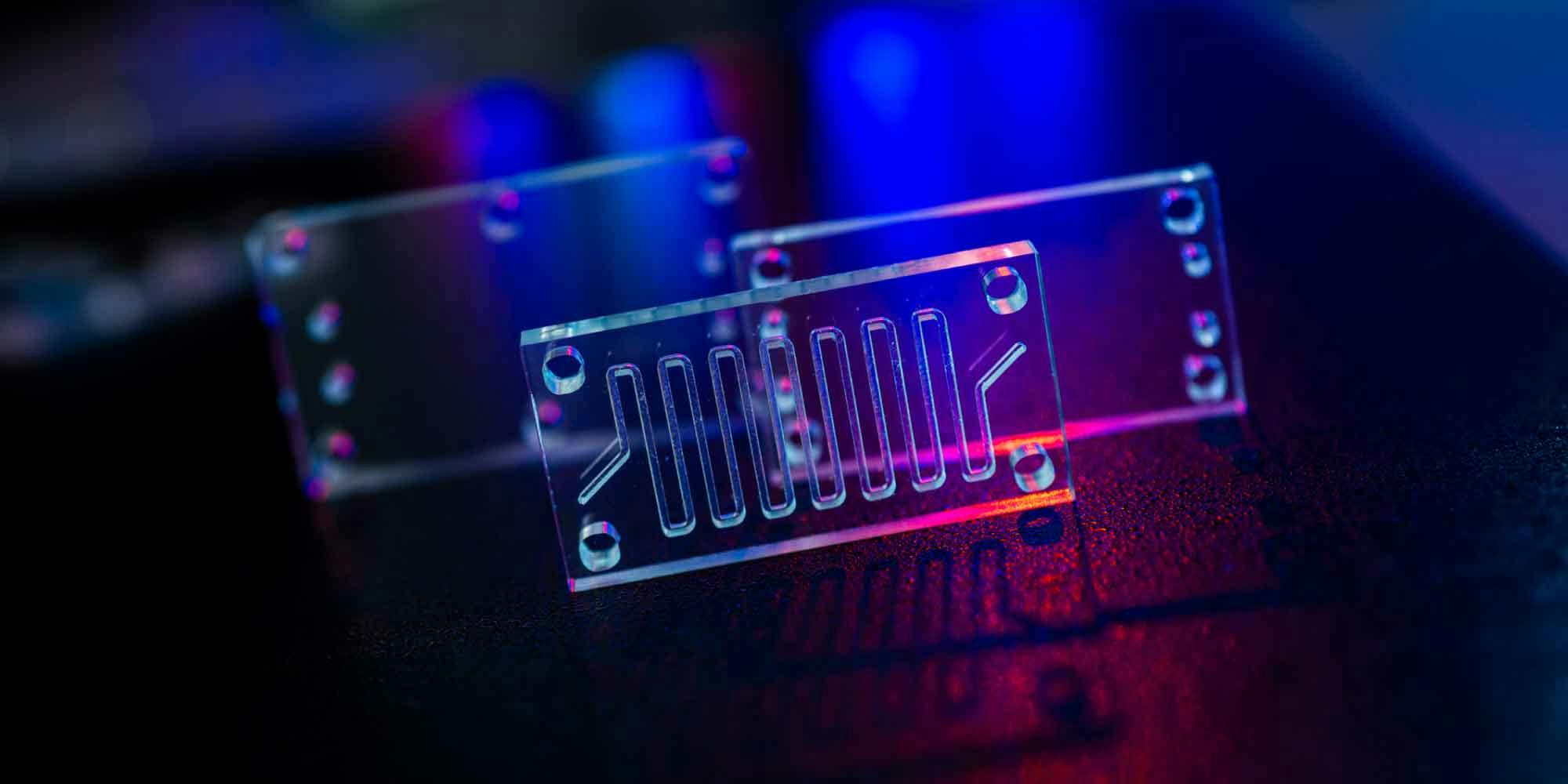

Imec develops integrated sample-to-result chips to perform PCR tests. For most microfluidic structures, we use silicon channels, sealed with glass. Silicon is more costly than polymers, and more complex to handle. But it also results in better prospects for mass production and easier integration of other lab-on-a-chip components such as sensors and signal processors.

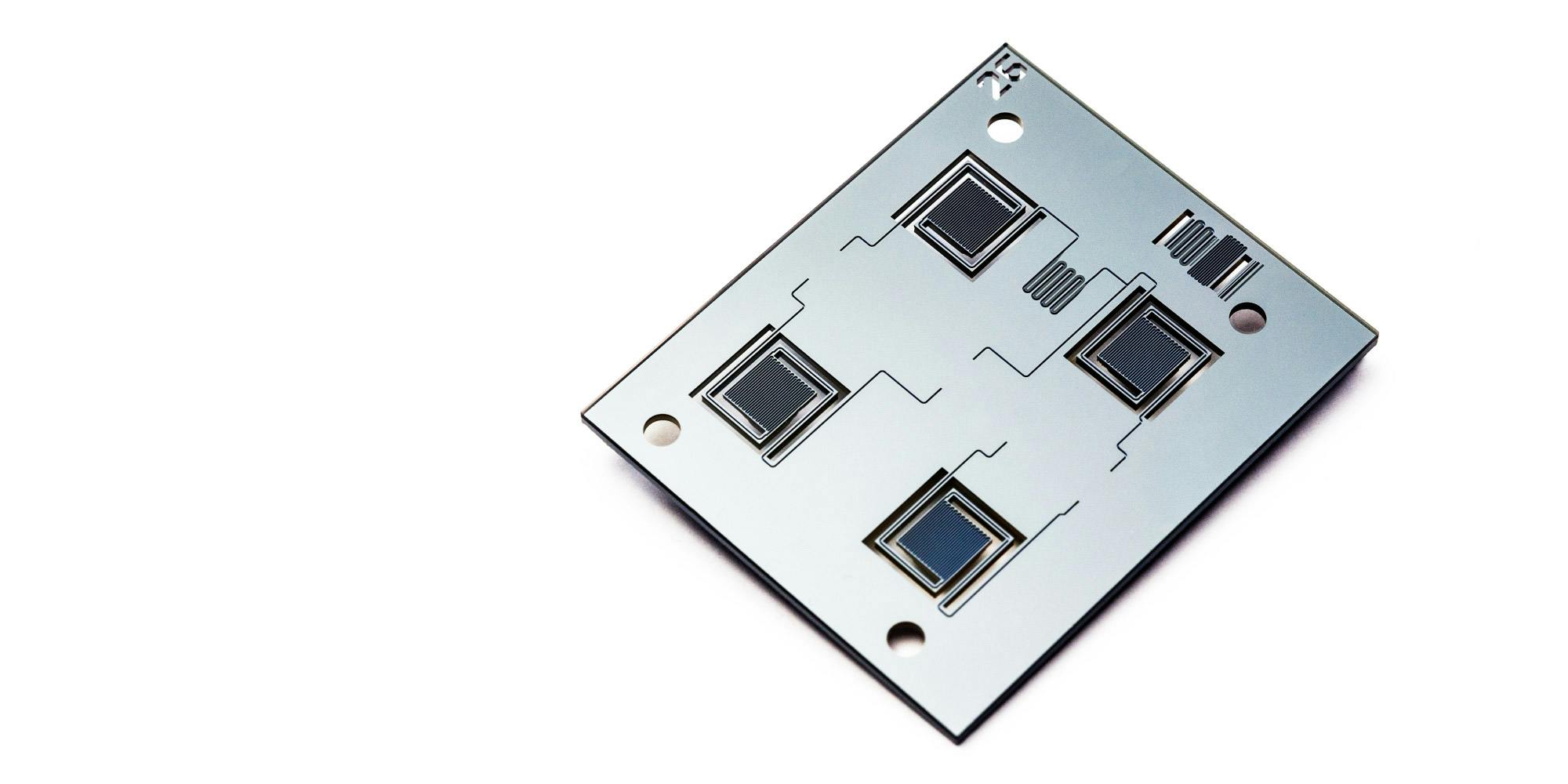

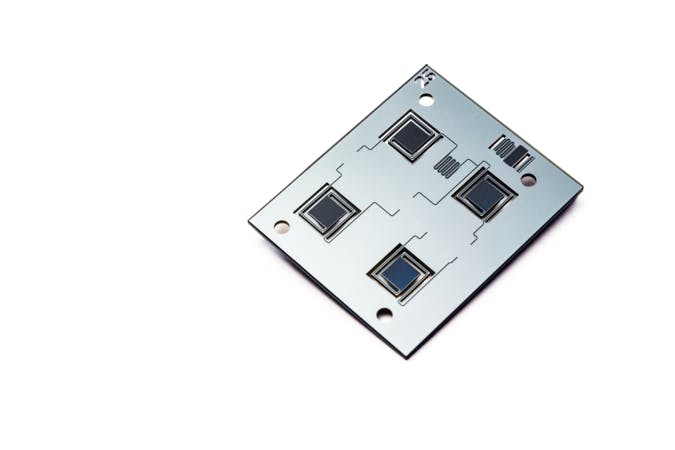

Imec’s integrated microsystem for detection of multiple single nucleotide polymorphisms directly in human blood.

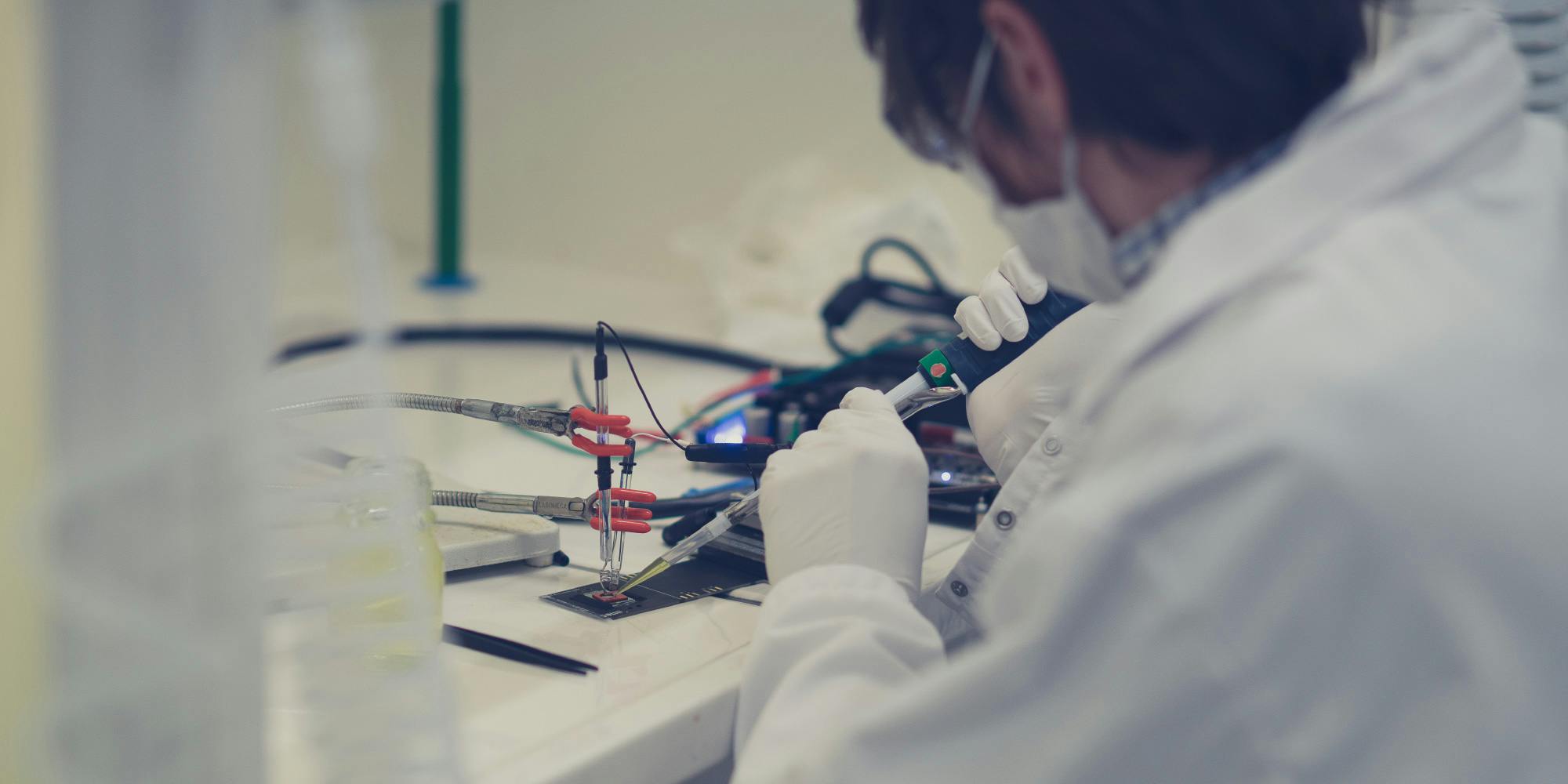

Imec’s on-chip technology stands out because of its capacity for extreme miniaturization and parallelization. It performs a full PCR analysis from whole-blood in less than ten minutes. The on-chip workflow integrates:

- filters

- mixers

- lysis

- extraction

- enrichment

- droplet handling

Digital droplet PCR (ddPCR)

Imec’s lab-on-a-chip platform also incorporates microfluidic components to generate, merge and split droplets. This enables a process called digital droplet PCR, a less cumbersome alternative for the well-established method of quantitative PCR (qPCR) using fluorescent markers.

Read this article for more insights into the importance of droplets for microfluidic systems

The goal of quantitative PCR is to establish not only the presence, but also the amount of a certain DNA molecule in a sample. Digital droplet PCR achieves this by:

- Dividing the sample into tiny droplets.

- Performing on-chip PCR on all the droplets

- Calculating the DNA concentration in the original volume based on the presence/non-presence ratio in the droplets.

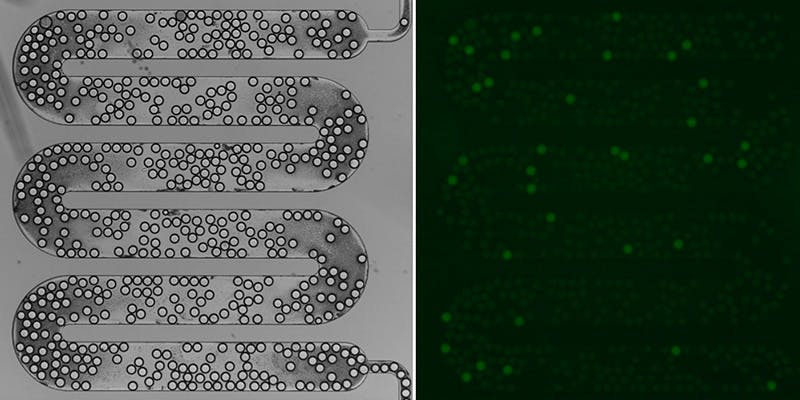

Microfluidic chip reactor of the digital droplet-based PCR chip for establishing a micro-RNA profile quickly for determining the type of cancer. The first photo depicts a chip reactor filled with droplets, at the right the same reactor, but after the PCR reactions. The luminous droplets contain a DNA molecule or molecules.

Because ddPCR dispenses with the need for calibration curves, it’s a very efficient and robust method. Moreover, it allows the detection of two DNA variants in a sample – even if one is much more abundant than the other.

Work with us

Want access to our on-chip PCR or ddPCR technology? Do you want to build a lab-on-a-chip solution to improve the throughput and accuracy of your processing while reducing the system cost and size?

Imec supports you with your R&D, process development and low-volume production. We create a whole lab on one cm² through monolithic integration of silicon microfluidic structures, micro-optics, photonics and electronics.