White paper cell therapy

Raising the bar in manufacturing cell therapy products

Nanoelectronics driving accuracy, improving turnaround times and increasing yields in cell therapy workflows

Introduction

The field of cell therapy reached a major milestone with the first CAR T products getting FDA approval: USD Kymriah of Novartis and Yescarta of Kite Pharma. It's likely that this is just the beginning of a wave of T-cell immunotherapy success stories. Now, the focus has turned to clinical adoption. That requires the manufacturing process to be more efficient, upscalable and standardized in order to achieve a safe and efficacious therapy for numerous patients.

The fact that the adoptive therapy consists of live cells, manufactured from T cells derived from the individual patient, represents major challenges for the process development. Today, this has resulted in a long production time (3 weeks to 3 months), high costs and – due to manual intervention at different stages in the process flow – a risk for contamination.

This whitepaper describes some unique results that clearly demonstrate how nanoelectronic sensors can contribute to a standardized, cost-effective and fully automated cell therapy process flow.

What you will learn

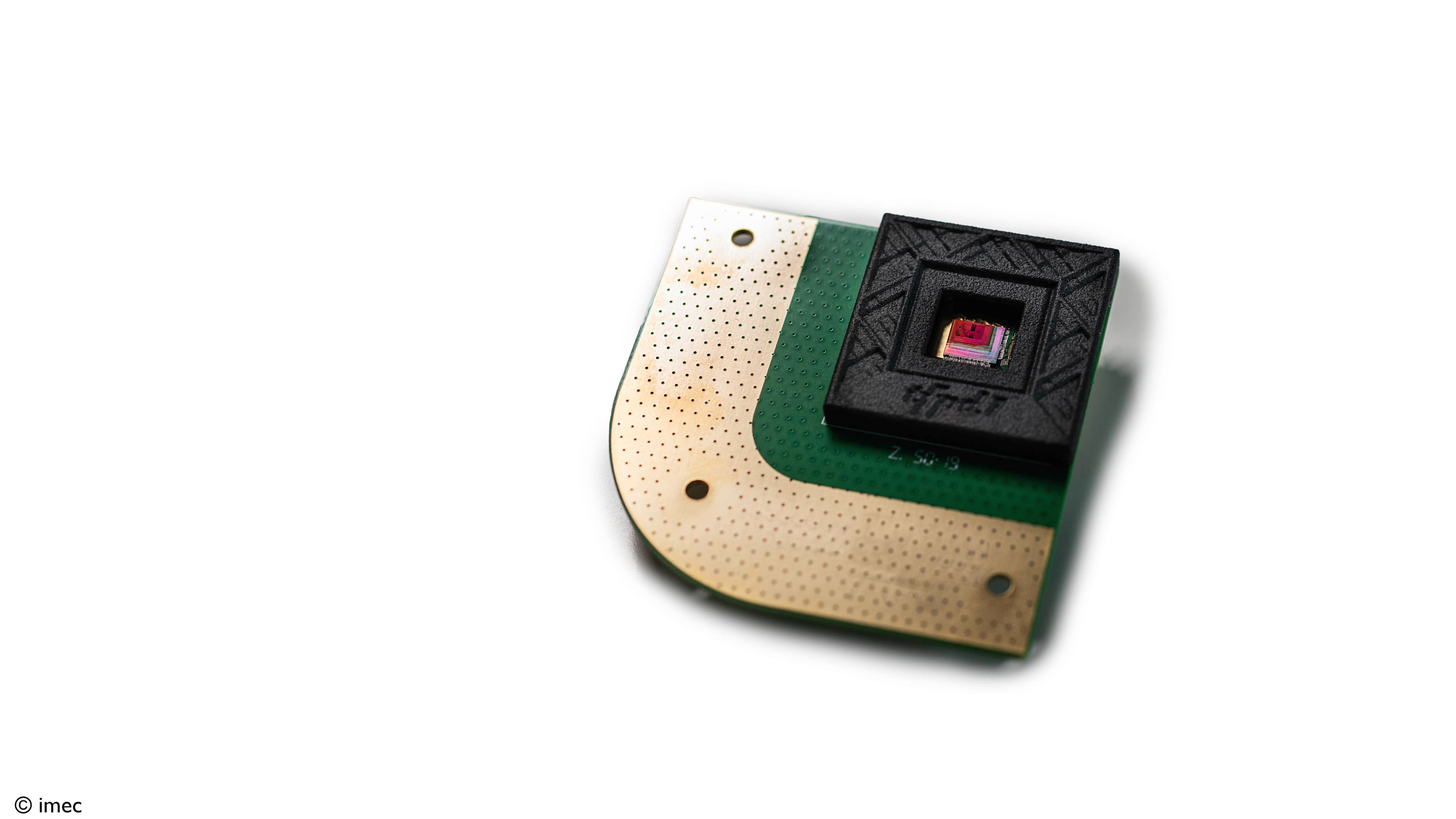

- How novel developments in nanoelectronics and silicon technology enable ully integrated sensor solutions combining microfluidics, photonics-based biosensors, single-cell manipulation, lens-free on-chip microscopy etc.

- How these technologies can be combined and integrated to drastically upscale and reduce the production cost and turnaround time of a (CAR T) cell therapy process flow

- How these technologies can be used to automate cellular analysis and to measure cell number, cell viability, cell morphology, growth medium parameters and cell products for improving the efficacy of cell therapies.

- How such an integrated and automated approach can significantly improve the cell therapy workflow both in terms of ease of use, reliability and reproducibility and scalability.