CMOS: advanced and beyond

Discover why imec is the premier R&D center for advanced logic & memory devices.

Integrated photonics

Take a look at technologies for optical transceivers, sensors and more.

Health technologies

See how imec brings the power of chip technology to the world of healthcare.

Sensing and actuation

Explore imec’s CMOS- and photonics-based sensing and actuation systems.

Connectivity technology

Look into our reliable, high-performance, low-power network technologies.

More expertises

Discover all our expertises.

Research

Be the first to reap the benefits of imec’s research by joining one of our programs or starting an exclusive bilateral collaboration.

Manufacturing

Go from idea to scalable and reliable semiconductor manufacturing with IC-Link.

Venturing and startups

Kick-start your business. Launch or expand your tech company by drawing on the funds and knowhow of imec’s ecosystem of tailored venturing support.

Education and workforce development

Imec supports formal and on-the-job training for a range of careers in semiconductors.

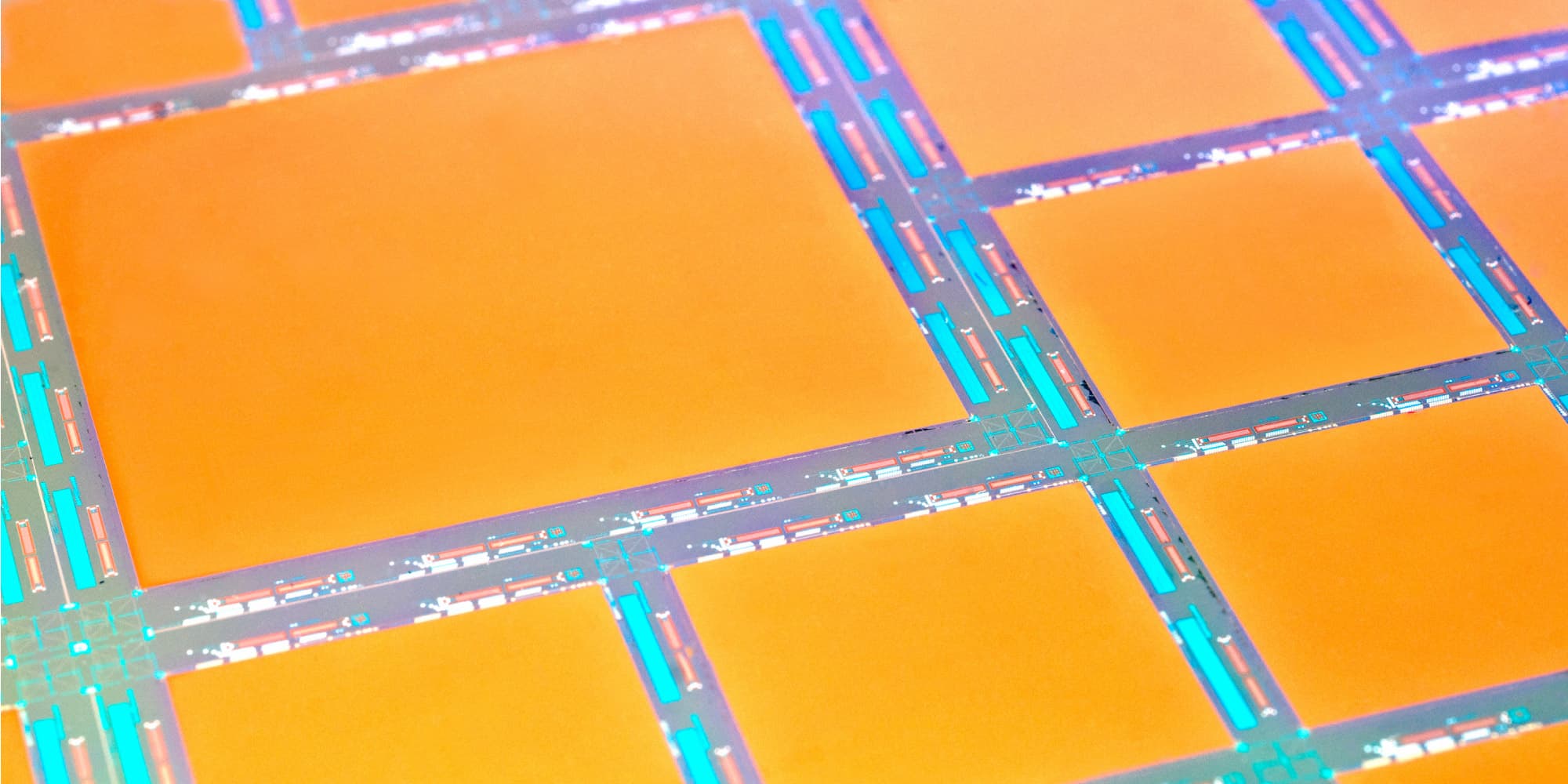

NanoIC pilot line

Aligned with the EU Chips Act, access to the pilot line will accelerate beyond-2nm innovation.

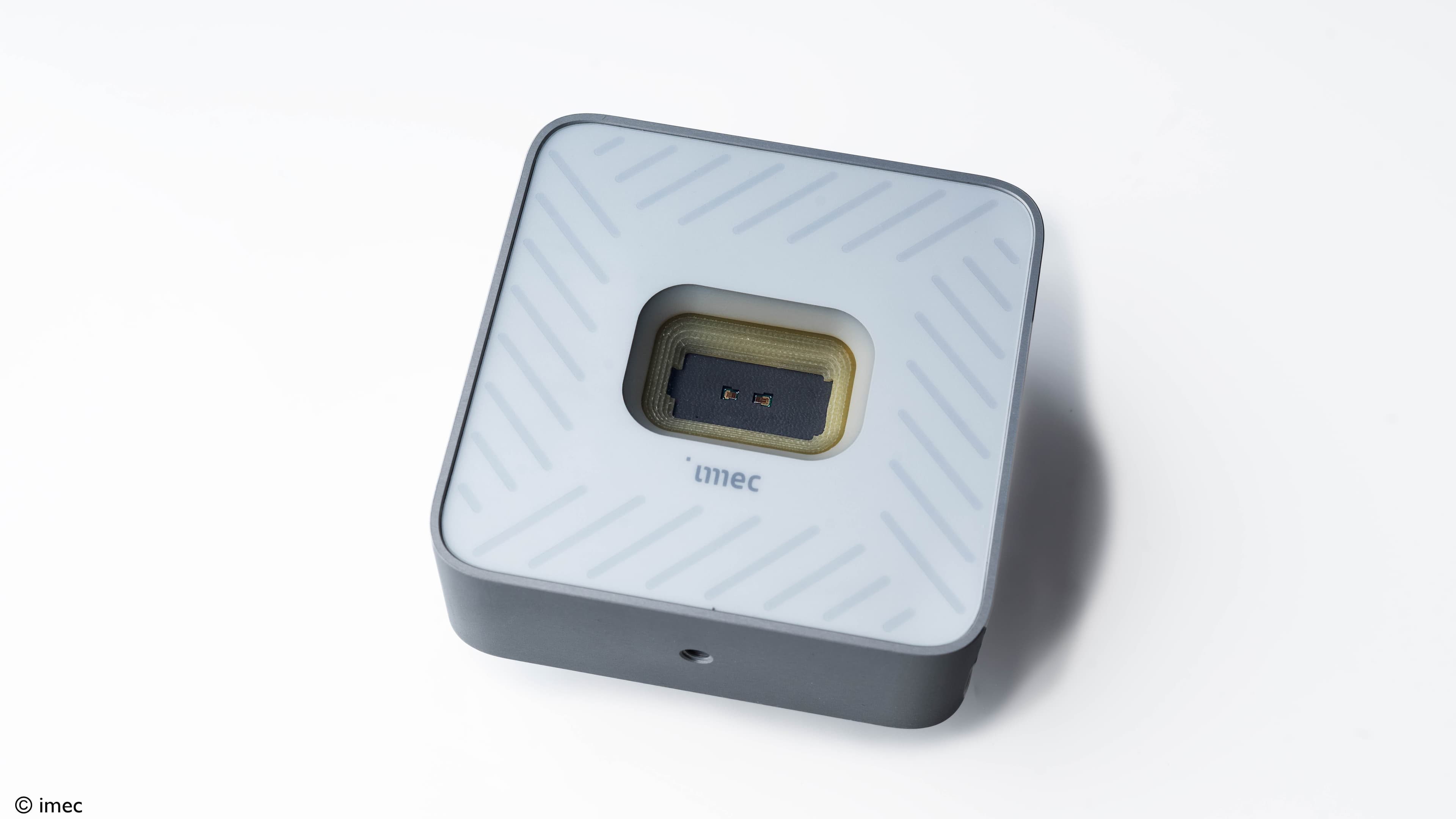

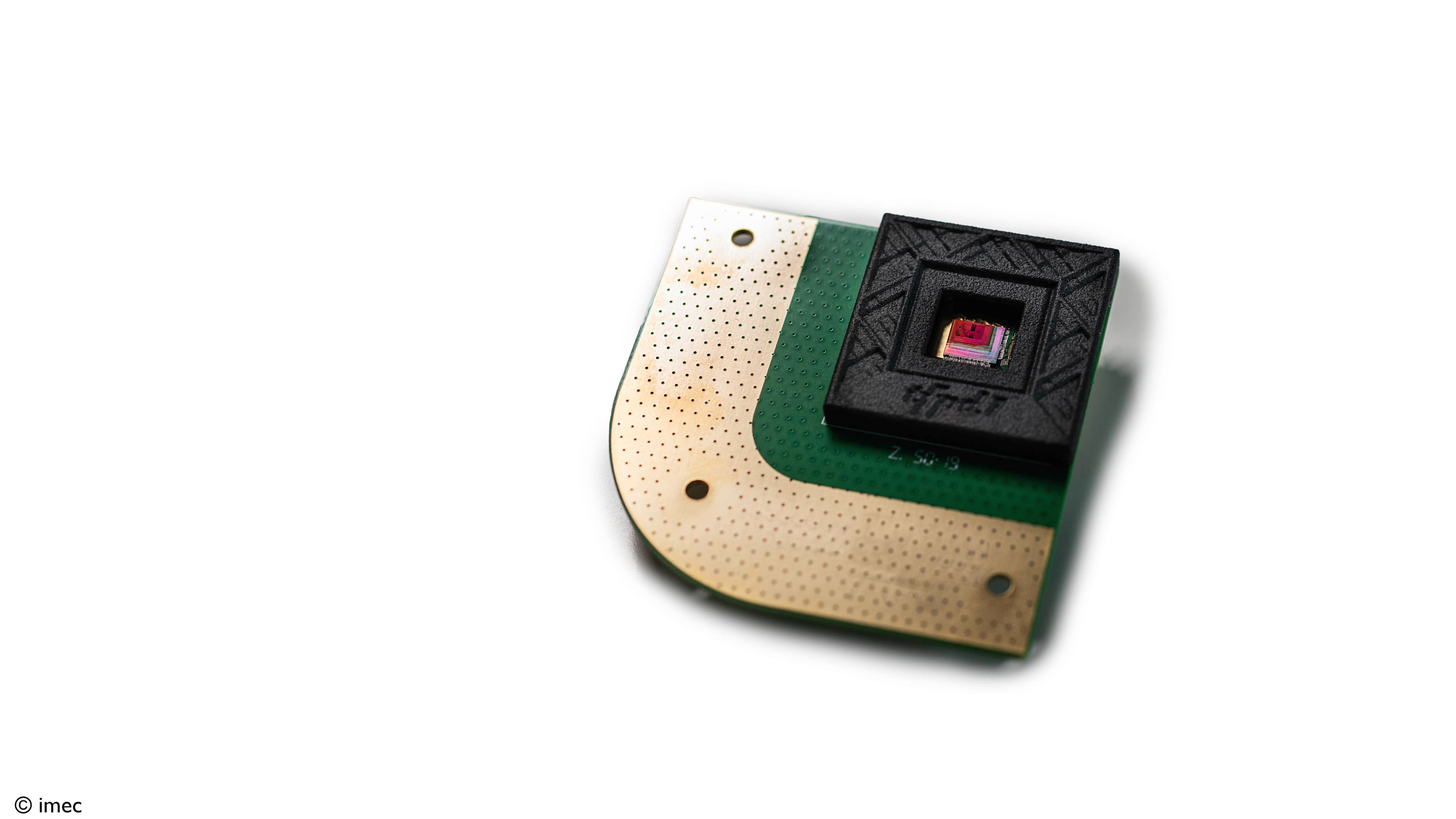

Sensing and actuation

Explore imec’s CMOS-based sensing and actuation innovations.

Sensor and actuator devices are multiplying in both consumer and professional domains. That’s in no small part due to the exceptional capability of semiconductor technology to downscale prices and form factors.

Imec aims to extend this path and enable new applications in domains such as life sciences and agrifood. We work on a wide array of sensor-actuator technologies – and their integration into comprehensive solutions.

Learn more about these technologies by clicking the images below. Or contact us directly for more information.

What can we do for you?

- We offer flexible collaboration models ranging from pure contract research for concept design, prototyping and low volume manufacturing, to full support in process technology transfer and licensing to a CMOS foundry for high-volume production ramp-up.

- We offer custom product development with strong engagement model of collaboration matching your own internal R&D team objectives.

Why work with us?

- Our comprehensive expertise includes image processing expertise, HW and SW system design, calibration, simulation and more.

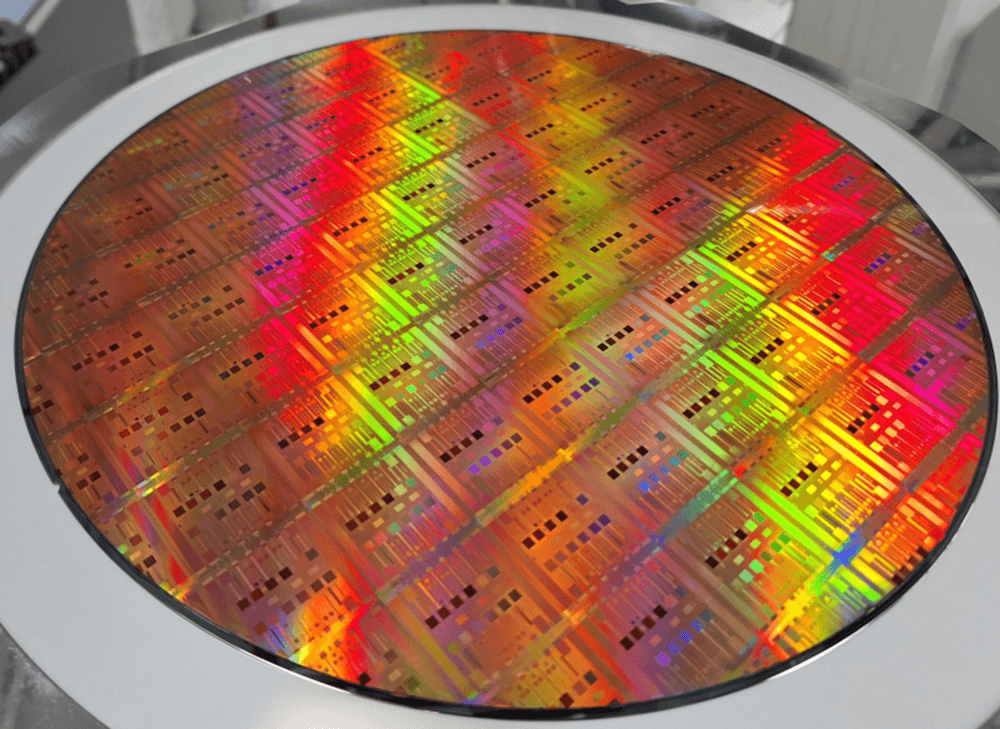

- Our unique CMOS semiconductor infrastructure includes a 1 billion euro state-of-the-art 200mm and 300mm cleanroom for process technology development.

- Ideal environment from early prototyping to ramping up small-volume production of up to 500 wafers per year per project.

Subscribe to our thematic newsletters