Electroplating of difficult to plate metals and alloys from non-aqueous solutions for fabrication of 3D nanomesh scaffolds

PhD - Leuven | More than two weeks ago

Many puzzle pieces are required to enable the energy transition towards a sustainable future. It is undeniable that production of renewable energy alone is not sufficient. Energy storage in the form of hydrogen, e-fuels or batteries, as well as other means of decarbonization, such as CO2 reduction to building blocks for the chemical industry, are required in order to limit and eventually reverse our impact on global warming.

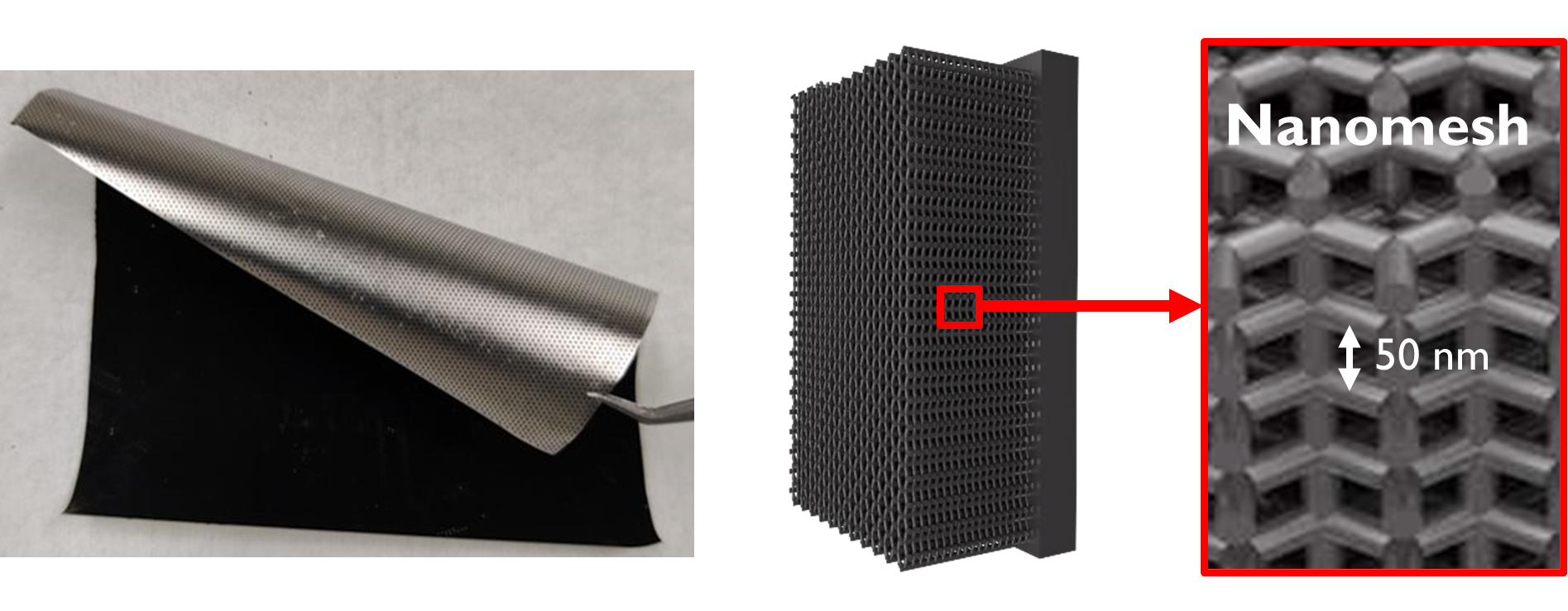

At imec we developed a novel type of nanostructured electrode with a unique combination of very high surface area, open porosity, and mechanical stability. Today, these nanomesh electrodes are already being developed for water electrolysis and CO2 reduction [1-3]. Apart from fundamental insights that will benefit the general applicability of these nanostructured scaffolds, the main focus of this project is to extend their scope of applications as electrodes for energy storage and conversion, but also as membranes, filters, heat adsorbers and even magnetic structures.

The nanomesh scaffolds are fabricated by template-assisted electrodeposition and today already metals and alloys from nickel, cobalt, copper, silver and platinum can be fabricated from standard aqueous solutions. For several other applications, however, difficult to plate metal and alloys from aluminium, titanium, tungsten, silicon and even carbon are of interest. For example, for acid water electrolytes, acid resistant current collectors such as Ti and W are required. For battery applications, Al current collectors are needed for the cathode. For bio-medical applications, stainless steel would be of interest. All these materials are difficult to plate and need non-aqueous electrolytes. Within this doctoral research you will develop electrodeposition processes for the fabrication of these nanomesh scaffolds and create fundamental understanding of their physical and mechanical properties. This incorporates a combination of state-of-the-art analysis methods and modelling of mechanical properties, with a deep dive into the geometry, crystallographic structure, and potential defects of these nanostructures.

Required background: Material's Science, (Electro-)Chemistry

Type of work: Mainly experimental

Supervisor: Philippe Vereecken

Daily advisor: Siggi Wodarz

The reference code for this position is 2025-147. Mention this reference code on your application form.