Being small, conceptually simple, fast and relatively cheap, lens-free microscopy enables an abundance of applications to which traditional microscopes are less amenable. Examples are particle monitoring in a cleanroom environment, or cell monitoring with the microscope integrated in the biotech tool. Built on earlier prototypes, imec now offers its lens-free digital microscope as a ready-to-use evaluation kit for life sciences and industrial applications. With this demo kit, companies can try out their own applications, and, with the help of imec’s engineers, fine-tune the tool towards their own requirements.

A lens-free digital microscope: small, simple, cheap and fast

Lens-free digital microscopy has recently emerged as an attractive alternative for optical microscopy in certain biomedical and industrial applications. The technique is conceptually simple: the interference pattern between the light that illuminates an object and the light that diffracts off an object is captured by a digital image sensor. The resulting digital hologram is then further processed to reconstruct an extremely detailed image of the object, including depth information. The setup requires only a light source, an image sensor and a powerful processor to compute the images. As such, lens-fee digital microscopy removes the need for expensive and bulky optical lens components to acquire and visualize microscopy images. At the heart of the setup is the digital image sensor. This image sensor determines important metrics such as the field-of-view and the spatial resolution of the microscope. The field-of-view may be orders of magnitude larger than what is possible with traditional microscopes, where it inversely relates to the tool’s resolution.

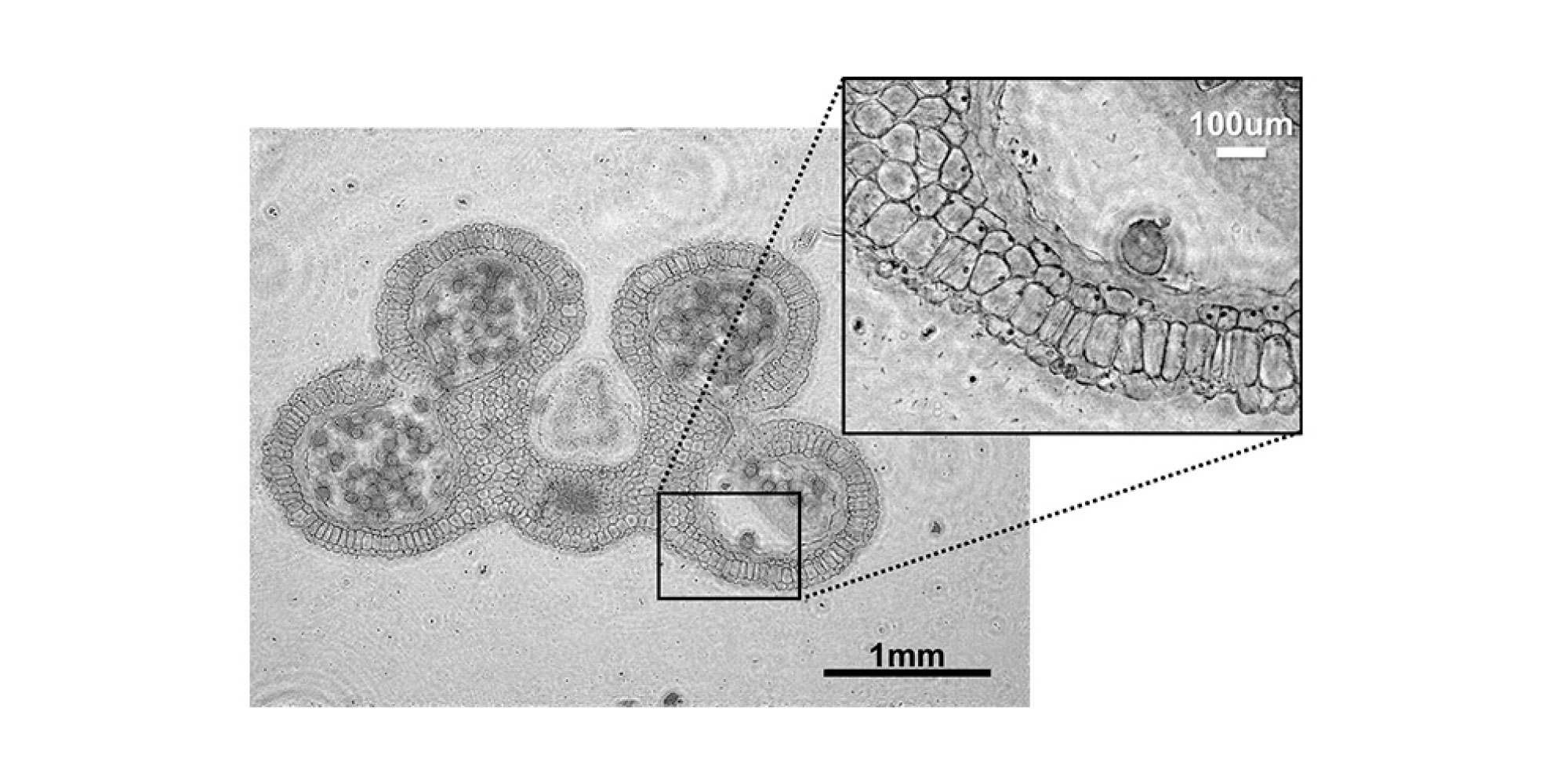

Full field-of-view (16.5mm2) lens-free image of a lily anther, with high-resolution details (zoom in)

An evaluation kit to try out

Originally built for in-house life sciences applications, imec has gradually deployed the technology for other, industrial types of applications. This was the starting point for turning the technology into a multiple-purpose platform, targeting various life sciences and industrial applications. Today, the focus is on the customization of the technology towards the requirements of its partners. Therefore, imec offers its lens-free imaging solution as a full, ready-to-use evaluation system. The demo kit contains a light source, an image sensor, control and read-out electronics, a software interface and a laptop with pre-installed imaging software. The system features a field of view as large as 16.5mm2 and a spatial resolution of about 1 micrometer. In the set-up, the lens-free microscope is coupled to an accelerated image processing unit (i.e., a graphics processing unit or GPU). This allows a fast and user-friendly operation of the system. Companies can use the evaluation kit to try out their own applications. Imec’s engineers can then adapt the system by fine-tuning the hardware and software towards the application requirements of the customers.

Detailed view of the acquisition stage of the lens-free microscopy evaluation system

Prototypes for life sciences applications

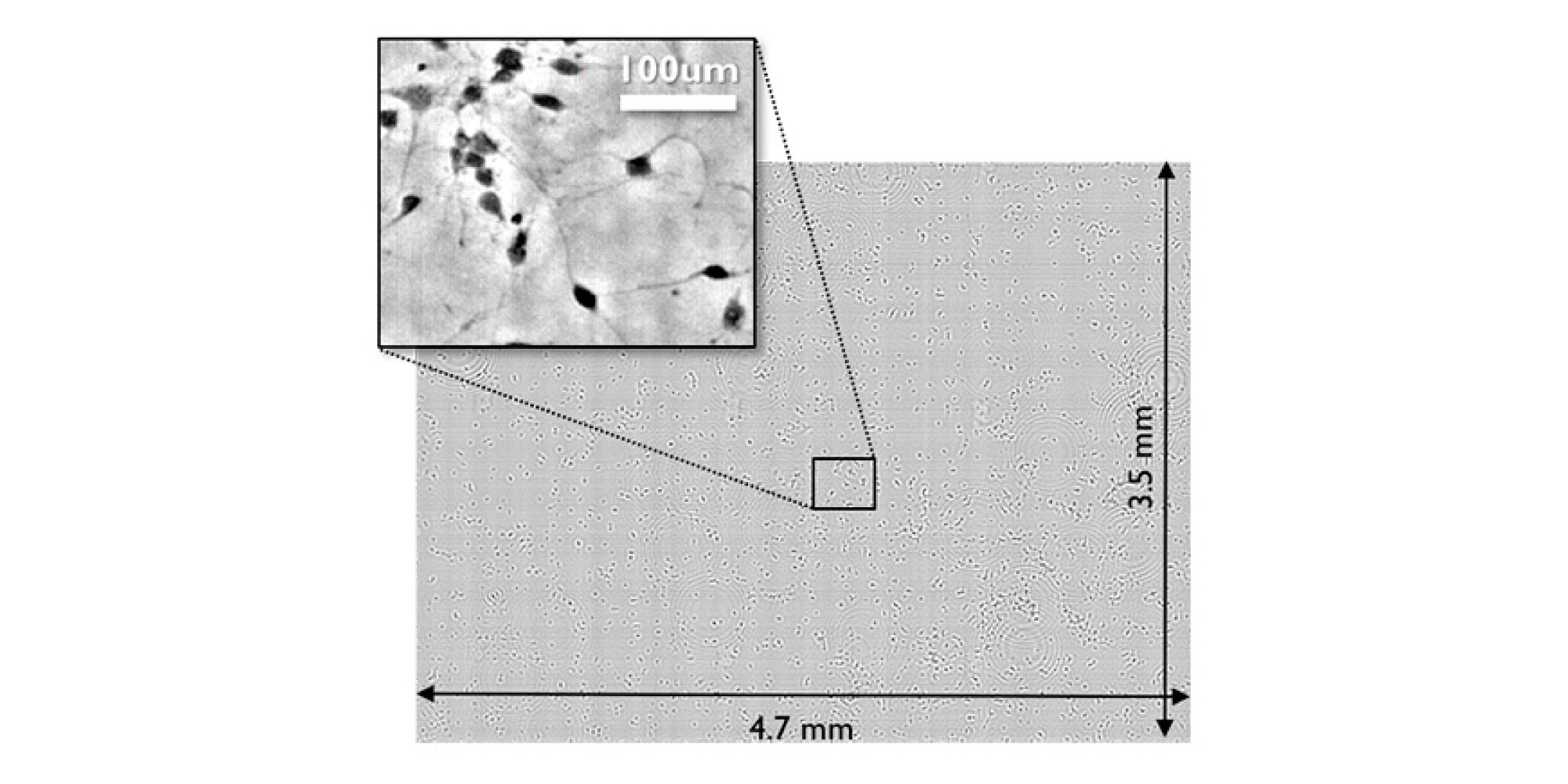

In the past, imec already built variations to the lens-free microscope setup to meet specific application requirements. One example is the integration of the lens-free microscopy system in a stem-cell incubator environment. In such incubators, stem cells grow and have to be inspected regularly to see whether the cells are thriving and when they can be harvested. In a traditional biological context, the inspection is done outside the incubator environment by using optical microscopes. But the quality of the cells may go down when they are manipulated too many times. Imec’s engineers have solved this problem by integrating the lens-free microscope into the incubator. This way, the cells can be inspected inside the incubator itself, without any manipulation. The selected image sensor yields a field of view that is large enough to monitor the entire cell colony (29mm2) and its individual cells at the same time.

In another prototype, imec adapted the field-of-view and the speed of the set up to enable the monitoring of contracting lab-grown layers of heart cells. The challenge was to monitor these heart cells and to follow the conduction speed from one cell to the next in a monolayer of cells. The acquisition speed of a lens-free digital microscope depends on the speed of the image sensor, but also on the speed with which the pictures are digitally computed. The researchers optimized both the computation and hardware setup, using a combination of a central processing unit (CPU) and a graphics processing unit (GPU). For this prototype, they achieved an imaging speed of almost 150 frames per second, with higher speeds possible. The availability of this setup creates a path towards testing potential new drugs on lab-grown layers of heart cells.

Playing with internals and form factors

The lens-free imaging technology is not necessarily intended to replace a traditional microscope, but rather to complement it. It is intended to go to places where the traditional microscope is either too large (e.g. inside an incubator), too expensive, or does not have a sufficiently large field-of-view (e.g. for monitoring contracting heart cells). And that’s one of the strengths of lens-free imaging technology. It can also be applied in even the most demanding situations, where traditional microscopy would just not be applicable. For example in a cleanroom environment to detect and classify particles (types and sizes).

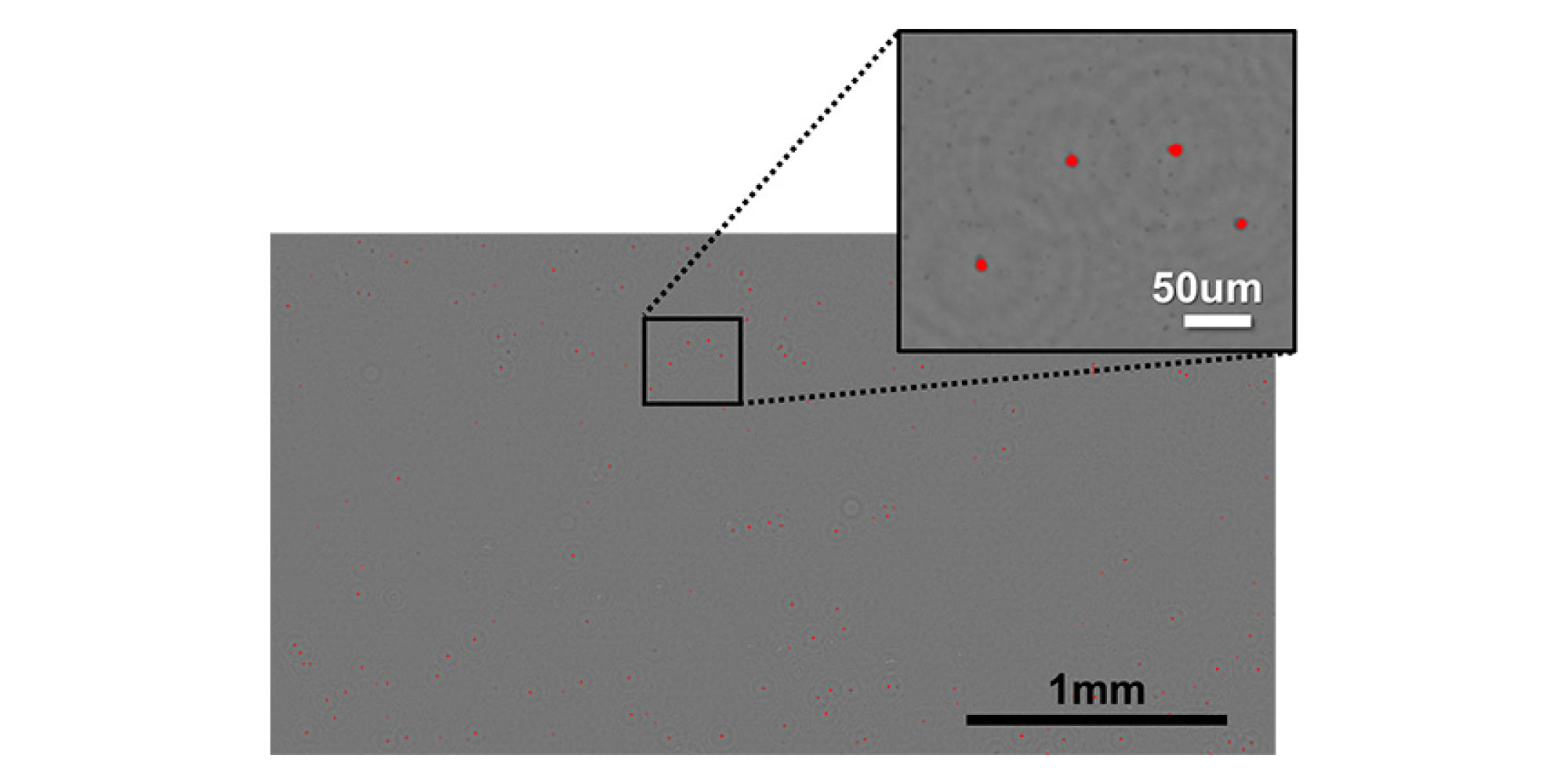

Particle detection with automated counting and classification, e.g. for cleanroom cleanliness monitoring applications

It can also be tuned to applications that require an ‘ultralarge’ field-of-view, such as for the inspection of thin-film displays. Thin-film displays are being produced with ever smaller pixel size. Traditionally, microscopes with a small field-of-view need to make thousands of mechanical movements to inspect the whole surface. And this slows down the manufacturing speed of the displays. A lens-free microscope offers the possibility of duplicating the image sensors, by placing them next to each other with no gaps in between. This allows extending the field of view in one dimension, ending up with a high-throughput scan stage. This massive duplication of microscopes is not possible with the traditional solutions. Imec’s team is currently exploring the ability to meet the requirements for inspecting thin-film displays. A similar solution could be useful for other applications as well.

As all these examples demonstrate, our multidisciplinary team of engineers, physicists, biologists and software experts can flexibly tune the specifications of the lens-free microscope to meet specific application requirements. They can play with both internal parameters (such as field of view and acquisition speed) and form factors. This will enable a variety of new applications that would not be feasible with traditional microscopes. As such, lens-free microscopes are becoming new building blocks for innovative biotech and industrial research and development.

Lensfree imaging single shot capture of fine neurite structures

The development of lens-free imaging microscopes is part of imec’s research domain on image sensors and vision systems, including also hyperspectral imaging, embedded CCD, backside illumination and ultrasound imaging.

On April 19 and 20, 2016, during the Industry Events at SPIE Defense and Commercial Sensing in Baltimore, USA, imec will present its latest results in CMOS-based hyperspectral imaging, embedded CCD and ultra-high-speed pixels, and also mm-wave radar solutions

Published on:

21 December 2016