Silicon photonics, in the footsteps of electronics

The evolution in electronic chips has made devices such as microprocessors and mobile phones more compact, lower-priced, and smarter. Also, for the medical community, they have been a game-changer with complex electronic functions packaged into small and smart boxes such as pacemakers and oximeters.

Today, the same technology as used for electronic chips, is being used to build circuits for the manipulation and transportation of light. Silicon photonics promises major advances for all kinds of medical devices that use light: scanners, microscopes, biosensors, spectrometers etc.

While silicon photonics was very much an academic topic 20 years ago, it now is a mature technology with a library of components such as waveguides, ring resonators, and multiplexers. Many commercial fabs have added this photonic technology to their portfolio for various applications including communication, LiDAR, and quantum. Also, the first set of medical photonic devices are reaching the market to make medical instruments more compact and more performant.

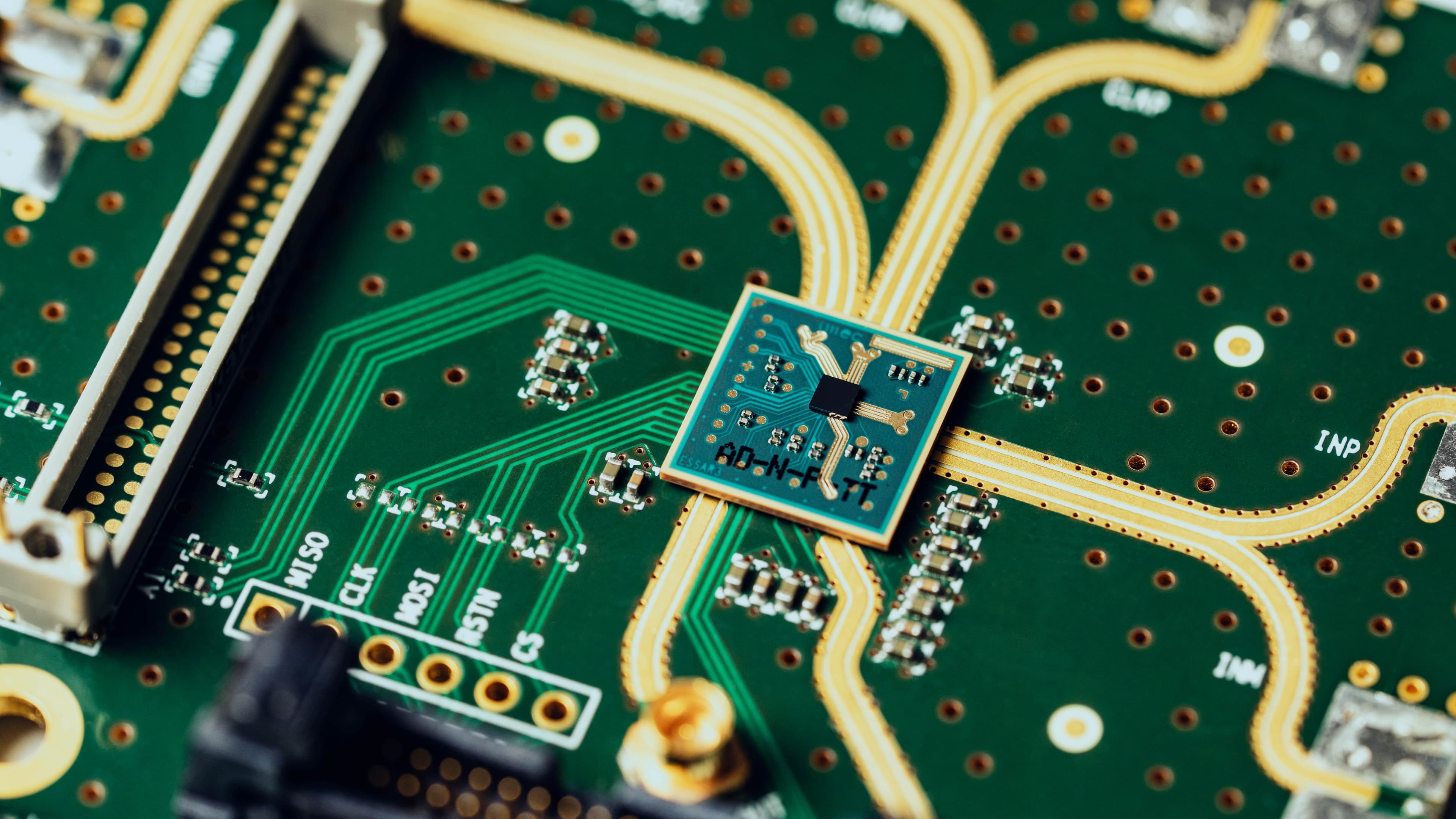

Compact, high-performance integrated laser for spectroscopy application. This hybrid integration chip with silicon photonics and III-V gain materials is only a few millimeters in size.

Research groups worldwide – among which also imec – are further building this ‘photonic’ road with the smart design of complex photonic circuits, more integration of specific photonic components, and the use of new materials to extend the wavelength range: silicon waveguides on top of silicon oxide material can be used to transport light with a 1 to 3µm wavelength; For applications using light with shorter wavelengths, it is better to use silicon nitride (SiN) waveguides and for longer wavelengths, germanium (Ge) waveguides are built.

For medical applications, the SiN-based technology is often the best choice since these applications are based on the use of visible light and require very low loss.

Depending on the light that is used in the medical application, different flavors of silicon photonics can be used with silicon, silicon nitride or germanium waveguides.

See the light with these 5 examples

Here are some striking examples that illustrate how silicon-based photonics can transform medical devices:

1. Optical coherence tomography (OCT): from desktop to handheld device

OCT is a non-invasive imaging technique that uses light waves to visualize the different layers of tissues. It is used in cardiology and dermatology, its broadest use is in ophthalmology to study the retina. It is an important tool for the diagnosis of and treatment guidance for glaucoma, macular degeneration and diabetic eye disease.

Today’s OCT scanners are expensive and quite large, filling up a table. By replacing the optics with more compact photonic components, it would be possible to make handheld, fast and low-cost OCTs. This would broaden its use towards point-of-care diagnostics, e.g. for newborns, children, bedridden elderly, and remote diagnosis.

Since 2010, imec has been researching silicon photonics for handheld OCTs. For example, imec has developed miniaturized interferometers based on photonic waveguides. Interferometers are the key building block of spectral-domain OCTs which use a broadband light source, such as a super-luminescent diode, and a spectrometer to measure the optical interference signals.

The most recent work in the domain of photonics for OCT is done in the framework of the European project ‘Handheld optical coherence tomography’. This collaborative project with Carl Zeiss deals with the monolithic integration of silicon nitride optical waveguides, germanium photodiodes, and micro-optics. In this project, the focus is on the hybrid integration of a novel compact all-semiconductor akinetic swept source which is a key component of swept-source OCTs. These are faster and have a longer imaging depth range than spectral-domain OCTs.

Photonic circuitry for optical coherence tomography.

2. Under your skin: a complete glucose monitoring system

The Belgian startup Indigo was founded in 2016 as a spinoff of the University of Ghent and imec, by researchers from its photonics research group. The company implanted its integrated photonic-based sensor in patients in their first clinical study.

The multi-metabolite sensor is a spectrometer-on-chip that measures glucose, ketone and lactate levels in people living with diabetes. It does this continuously while being implanted under the skin. This helps people with diabetes to live more normal lives without the need for an external monitoring system. The fact that ketones can also be monitored will add to their life quality since this is an important metabolite to protect them from developing ketoacidosis.

The inert, miniature integrated silicon photonics spectrometer chip measures the absorption of light in the interstitial fluid under the skin to quantify the concentration of multiple metabolites simultaneously without the use of enzymes or fluorophores. It securely and wirelessly connects to mobile devices to show and capture concentration profiles of metabolites for the user. A rechargeable sensor battery powers the measurements.

Photonic spectrometer-on-chip for biomarker detection for diabetes patients. At the right is a mockup of the application. (copyright: Indigo)

3. Detecting cardiovascular diseases by shining light

In the European project CARDIS, nine research partners including imec and Medtronic, developed a prototype medical device to screen arterial stiffness and diagnose cardiovascular diseases such as arterial stenosis and heart failure.

The low-cost handheld device houses a silicon photonic chip containing the optical functionality of a multi-beam laser doppler vibrometer device. A very low power laser is directed to the skin overlying the artery. The skin’s vibration amplitude and frequency, resulting from the heartbeat, are extracted from the Doppler shift of the reflected beam. The device includes two rows of six beams, thereby scanning multiple points on the skin above the artery in parallel.

Prototype device for the diagnosis of cardiovascular diseases (left) and design of the photonic chip inside (right).

4. Photonic biosensors for diagnostics

Imec and Genalyte collaborated on making photonic-based biosensor chips for Genalyte’s diagnostic equipment. The chips contain up to 128 proprietary ring resonator sensors coated by Genalyte with application-specific chemistry to create very sensitive molecular detection capability. This bio-compatible passivation technology was developed on waferscale (200mm wafers), making it more cost-effective. On-chip grating couplers were used to couple the infrared light from and to Genalyte’s diagnostic equipment.

Wafer with photonic-based biosensor chips developed by Genalyte and imec.

5. A fluorescence microscope-on-chip

Fluorescence microscopy has evolved to become an indispensable tool in biology and medicine. Such microscopes are typically expensive, bulky devices that require highly skilled operators. The next big step in microscopy is the development of high-resolution microscopy on a single chip. Because the microscope is smaller and more affordable, more of them would be available in the lab. As a consequence, experiments could be set up in a different way: studying more parameters simultaneously in real-time.

After developing a compact on-chip solution for bright-field microscopy (for use cases such as inspection of cell cultures in incubators, particle or blood cell counts, scratch & defect detection in industrial inspection systems), imec is now focusing on fluorescence microscopy (for use cases such as DNA sequencing, biological research and drug testing). It uses photonics on chip to create light interference patterns for very high resolution fluorescent excitation. The work is done in the context of an ERC Starting Grant project IROCSIM.

The microscope contains an image sensor (a pixel array), topped with an integrated photonic circuit consisting of waveguides and phase modulators that form focused illumination spots to selectively excite the fluorophores in the sample. Unlike in a confocal microscope that operates traditionally with one focus point, many spots are generated and scanned simultaneously. Because the integrated photonic circuit where the spots are generated is very close to the image sensor, the numerical aperture of the on-chip microscope is inherently high. The chip presents a high-throughput alternative to conventional microscopy, especially for sequencing-related applications or for cell imaging for drug development.

The concept of the fluorescence microscope on chip. Illumination spots are generated in the photonic circuit. The imager picks up a signal where the light excites the fluorophore.

An advanced Si and SiN platform available for companies

Imec has set up two platforms for photonics, based on silicon or silicon nitride as the core material, and with an extensive library of experimentally verified components. Silicon nitride is especially interesting for life science and medical companies, using visible light in their applications.

These photonic platforms are highly advanced and versatile. The best evidence for this is that it overcomes one of the biggest challenges in the photonics world, i.e. including an integrated light source. Because silicon and silicon nitride cannot emit light efficiently, other light-emitting materials need to be used to build an integrated light source in a photonic circuit. Imec uses III/V materials such as indium phosphide to build an on-chip laser.

Imec’s Si and SiN platforms include an integrated light source, based on indium phosphide.

Another interesting feature of imec’s advanced SiN photonics platform is its clad opening technology. This technology allows opening up the top of the wafer, thereby exposing the waveguide. The cavity on top of the waveguide can contain a gas or fluid that needs to ‘sensed’, which is interesting for sensing applications, for example.

The platform also includes technology for advanced SiN thickness control at wafer level (for 200mm wafers). Different techniques are available to deposit the SiN films: low-pressure chemical vapor deposition, plasma-enhanced chemical vapor deposition, and advanced SiN film deposition. The latter generates the best results in terms of uniform film thickness across the wafer, which is key for building photonic circuits efficiently.

Good film thickness control is essential for efficiently building photonic circuits on silicon wafers.

And finally, the platform allows building photonic circuitry on top of CMOS wafers such as imager wafers. This is extremely interesting for applications such as OCT and spectrometry.

It’s not an academic lab, and it’s not a foundry. It’s imec

In the academic world, much work is done on photonics, focusing on new concepts, simulations, and prototyping. At the other end of the spectrum are the commercial fabs where the most mature standardized photonic components are made in very large volumes. For medical technologies the required volumes are somewhere in the middle and it is hard to find partners helping to bridge the gap.

Imec tries to bridge the gap , developing new non-standard photonic components that are manufacturable. Moreover, imec can also provide small-to-medium volumes of photonic components and circuits. All research, development, and manufacturing is performed at the heart of the imec campus - its 200 and 300mm cleanroom - packed with state-of-the-art semiconductor manufacturing equipment.

Lowering the barriers to entry

For the European industry, imec is strongly involved in all kinds of initiatives that further lower the threshold to derisk novel photonic components that might make it to commercial products. For example, a unique platform for SiN photonic components and circuits was set up by the European project PIX4life, aiming to lower the entry to SiN photonic platforms via multiproject wafers as well as to create according design and packaging services. Next, imec participates in MedPhab, a European initiative to reduce the derisking cost and in that way accelerate the commercialisation of diagnostic devices and instruments based on photonics. And the goal of the future PhotonHub is to provide a full-service one-stop-shop Photonics Innovation Hub to provide companies, in particular SMEs and mid-caps, for different sectors with open access and guided orientation to a broad range of photonic services and capabilities.

In conclusion, we can say that both the technology and the fabrication scene are ready for companies to fully benefit from the enormous potential of integrated photonics for medtech applications.

Want to know more?

Read the paper ‘Novel light source integration approaches for silicon photonics’ published in Laser & Photonics Reviews.

The publication ‘Silicon nitride photonic platform for sensing applications’ gives more details on the clad opening technology.

Read the press release “Imec Joins Forces With Sivers Photonics and ASM AMICRA to Accelerate Hybrid Integration of InP Lasers and Amplifiers with Silicon Photonics”

Go to our dedicated webpage on integrated photonics to get a good overview of our capabilities.

Have a question on imec’s silicon or silicon nitride technology, or on the different kinds of business modes? Contact us.

Published on:

12 November 2021