There is a lot to be said about a new type of solar cell, based on perovskite material. This unique material was discovered in the Ural Mountains in 1839 and could in the future - thanks to clever interventions by scientists - produce solar cells that are cheap and achieve more than 35% conversion efficiency. The stability of the cells has improved considerably, allowing them to come to market within a few years, both for solar cell parks and for applications in cars, clothing, windows and façade elements. They are also the most environmentally friendly option in the PV world in terms of material use and production process. And, it is a type of solar cell that is best produced locally.

Tom Aernouts, program manager of Perovskiet PV at imec/EnergyVille and Soliance Solar Research, answers 5 pressing questions about perovskite solar cells.

1. What makes perovskite solar cells so special?

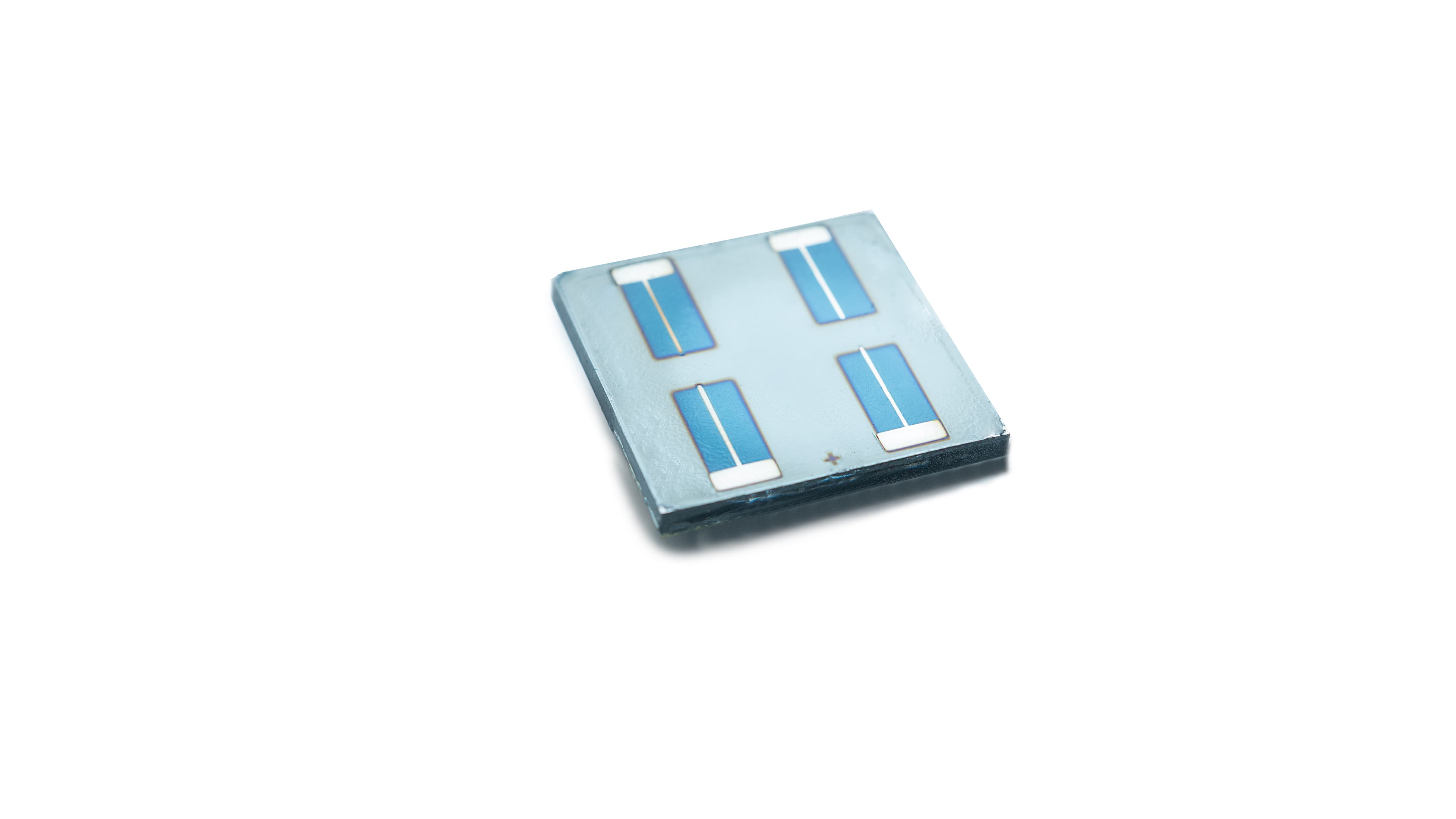

Tom Aernouts: "Never before has progress been so rapid with a solar cell technology as with the perovskite (Pk) solar cells: from 3.8% to 25.2% in 10 years time. It was in Japan, in 2009, that researchers first used Pk material for solar cells. The solar cell itself did not yet offer much with a low conversion efficiency (3.8%), a small surface area (0.24 cm²) and a stability of only a few minutes. But thanks to a worldwide effort - also at imec - we are now able to achieve more than 25% with lab cells".

"The production process is also relatively simple; the cells can be used at lower light intensities, and the material is relatively cheap and available in large quantities. In addition, the solar cells can be made translucent, in different colors and also on flexible substrates."

"The material is quite fascinating. The first perovskites used in research were minerals that were mined in nature. The first member of the Pk family was calcium titanate (CaTiO3), mined in 1839 by the German chemist Gustav Rose during an expedition in the Ural Mountains. He named the mineral after the Russian mineralogist Lev Perovski. All materials with the same crystal structure as calcium titanate - XIIA2+VIB4+X2-3 - which were subsequently discovered or synthesized, were given the name 'perovskite'. This family of materials is huge, precisely because of the enormous flexibility in ions that can be used in the formula. More than 90% of the metals in the Mendeljev Table can be used. In this way you can perfectly 'tune' Pk for certain wavelengths or applications."

Comparative graph showing the evolution of different solar cell technologies. The strong growth of perovskite-based cells is striking. (Source: EPKI White Paper)

2. Is it just a hype, or will they soon actually appear in real-life applications?

Tom Aernouts: "The stability of Pk solar cells has long been a problem and the PV industry was very sceptical about this new kid on the block. But here too, a lot of progress has been made and I expect the first Pk solar cells to roll off the belt within 2 to 3 years. In the EPKI White Paper we state that the production capacity (worldwide) will increase from 0.4 to 1.3 GWp in that period. Dozens of companies around the world are preparing their production processes and expanding their production capacity. One of them is GCL in China, but I strongly believe that Europe can also play an important role in this new technology."

"There is a standard test for (silicon) solar cells to guarantee a service life of 20 years. By 2020, Pk cells will be able to pass this test. The question is whether this test can offer the same guarantees - 20 years lifespan - for Pk cells as it was specifically developed for Si cells. Therefore, in parallel, the research community needs to gain more insights into degradation mechanisms in Pk cells in order to develop new, more suitable tests in the long run.”

"There are two types of Pk-based solar cells that are worth mentioning: the silicon cell with a layer of perovskite on top of it and the pure thin-film Pk cell. I expect it to be the Si-Pk tandem cell that will first be available because there is a big push from the Si-PV industry."

"Si solar cells are now almost at their limit in terms of conversion efficiency and with that extra layer on top of it, it can give a huge boost to efficiency. And that without drastically changing the production process. This type of cell will mainly be used in solar cell parks. For solar cell parks in less sunny areas - where the light intensity and clouds are more variable - bifacial Si solar cells can also be used with a layer of perovskite on top. The second option – thin-film Pk cells - will be used in other applications, integrated applications, such as in cars, building materials, windows, clothing, etc. As this requires a completely new approach, this type of Pk-based cells are likely to appear on the market a little later."

Perovskite solar cells are ideal for integration in building elements (BIPV) or in cars (VIPV). Here is an example of vehicle-integrated PV (not based on perovskite), from the Dutch startup Lightyear.

3. Where will these cells be produced?

Tom Aernouts: "Pk solar cells for integrated applications (in cars, buildings, etc.) are best produced locally because each market has its own regulations and organization that is strongly country-specific. So it is a great opportunity for Europe - which also has a lot of expertise in the field of Pk material and cells - to become an important player in this story."

"For the Si-Pk tandem solar cells, it is possible for Europe to purchase cheap silicon cells in other countries to then apply the Pk finish on it locally. Assuming, of course, that Europe makes good use of its expertise and rapidly expands its production capacities."

4. Are perovskite solar cells really going to be cheaper than the already cheap silicon cells?

Tom Aernouts: "The Si-Pk tandem cells will be more expensive than the current Si-cells because of course extra process steps and material are needed compared to the standard cells. However, the gain in efficiency will compensate considerably for this extra cost, resulting in a lower euro/watt peak. Si-Pk modules will certainly win the race with current cheap Si modules."

"Thin-film Pk cells have the potential to be very cheap. Of course, the final price will depend on the material used, the design of the stack and the type of process used, as well as the application and market size of this application. But as a guide price the EPKI White Paper mentions about 20 eurocents/Wp for the next 5 to 10 years with a reduction to 10 and maybe even 4 eurocents/Wp as further progress is made in the development and efficiency of the cells."

5. Doesn't the lead in perovskite solar cells make them environmentally unfriendly?

Tom Aernouts: "Pk technology is considered to be the most environmentally friendly PV technology available, due to, among other things, the use of synthetic-manufactured material (which does not require mining or complex purification processes), the very small amount of material required, and the low process temperature.”

“The best efficiencies are achieved today with lead-containing Pk cells. Alternatives are being considered, but they do not score very well for the time being. The amount of lead in the cells is very low: the lead-containing layers in a Pk cell are typically about 0.3µm thick, which translates into 1g of lead iodide/m². This is in accordance with the RoHS directive. In addition, solutions are being sought to further minimise the very small chance that lead would end up in the environment as a result of damage to the PV cell. E.g. by integrating materials in the cell that bind with the lead in case of exposure and form water insoluble components."

Want to know more?

EPKI, the European Perovskite Initiative, launched a white paper in September 2019 that gives a good overview of the latest results, the market, possible business models, etc. You can download this paper here.

Dr Tom Aernouts, R&D Manager Thin-Film PV at imec, initiated the research on thin film solar cells at imec in 1999. Till 2006 he was researcher working on fundamental understanding of organic solar cells and developing bulk heterojunction solar cells and fully flexible modules. Since 2006, Dr. Aernouts is group leader of imec’s Thin Film PV group, steering imec’s thin film PV research activities, with a first infrastructure upgrade in 2009 enabling processing devices up to 15x15cm², and a next upgrade just completed in 2018 to extend the device size to 35x35cm². The group has extended its activity in 2014 with the work on hybrid, perovskite-based thin-film solar cells. In a short period of time this group has attracted a lot of attention with its fast progress in this field with world-record certified module efficiency of 12.5%, as well as a recently reported world’s first 4cm² module-on-cell perovskite/silicon stack with a power conversion efficiency of 25.3 percent, outperforming the standalone silicon solar cell. Also, first modules on 30x30cm2 have recently been successfully processed. Dr. Aernouts received his M.Sc. in semiconductor physics from the KU Leuven, Belgium, in 1998, and a Ph.D. in Science in 2006 from the same university.

Published on:

4 November 2019