Artificial leaves for solar fuels generation

Genk | More than two weeks ago

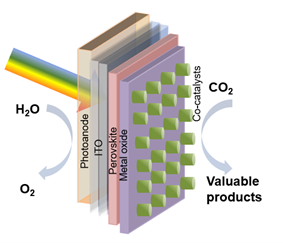

Photoelectrochemical conversion of CO2 to valuable products

The adverse environmental impacts of CO2 emissions are driving the demand for sustainable approaches to clean-energy production. CO2 can be converted to value-added products through photoelectrochemical reactions using solar energy. However, the thermodynamic and kinetic challenges associated with such a reaction make it a complex system. The key elements for achieving high direct solar-to-fuel conversions are semiconducting materials and co-catalysts. When a semiconductor material is exposed to light, it generates electrons and holes that have the potential to conduct oxidation and reduction reactions. Co-catalysts can be employed to lower the energy barrier for these reactions further and enhance selectivity for the desired product. Therefore, there is a significant interest in developing efficient photo absorbers and co-catalysts to improve energy conversion and catalytic activity. The semiconducting-co-catalyst systems can deliver a standalone device that mimics the functionality of leaves by converting CO2/H2O to energy.

In this project, you will fabricate perovskite-based thin films as photocathodes via state-of-the-art deposition processes and tools. These perovskite layers will be coated with multiple layers of metal oxides and co-catalysts to promote the intended photo(electro)chemical reaction. You will conduct various electrical, physical, and photo(electrochemical) characterizations and studies to evaluate their performance for solar fuel generation in different electrolytes. Thanks to your study, by combining with a suitable photoanode developed by our group, you will fabricate a standalone artificial leaf-like device that reduces atmospheric CO2 to valuable products like CH4, CH3OH, or water to H2.

The work will be conducted in the newly built laboratories at imec in EnergyVille, Genk, working in one of the world’s premier research centres for energy research.

Skill required: background in semiconductors or photo/electrochemistry. Good knowledge of device physics, nanotechnology, and lab process.

Type of project: Combination of internship and thesis

Duration: 3 months

Required degree: Master of Engineering Technology, Master of Science, Master of Engineering Science

Required background: Chemistry/Chemical Engineering, Electrotechnics/Electrical Engineering, Materials Engineering, Nanoscience & Nanotechnology, Physics

Supervising scientist(s): For further information or for application, please contact: Vishal Kakkarakunnel Jose (Vishal.KakkarakunnelJose@imec.be) and Anurag Krishna (Anurag.Krishna@imec.be)