Deepening insights into the spray coating of perovskite films for solar cells

Genk | More than two weeks ago

Spray coating is a promising scalable deposition method used in the fabrication of perovskite solar cells. Understanding the perovskite deposition via spray coating more in-depth could lead to higher quality perovskite absorbers and therefore higher power conversion efficiencies

Perovskites are considered as promising absorber materials for use in next-generation thin film solar cells. Firstly, due to their high absorption coefficient, perovskite absorber films can be made very thin (~ 600 nm) compared to the ~ 100 micron thick silicon absorber films in conventional silicon PV. This allows to obtain thin film solar cells, which can be made flexible, lightweight and also semi-transparent. Further, perovskite solar cells have the potential to be fabricated inexpensively and with a low CO2-equivalent footprint, thanks to low-temperature deposition methods such as spray coating. EnergyVille has achieved efficiencies close to 17% with in-house spray-coated single-junction perovskite solar cells.

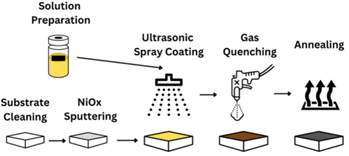

The in-house deposition of perovskite films via spray coating is demonstrated in the figure below. After sputtering a 15nm NiOx layer (used as a hole-transporting layer) on a glass sample, a perovskite precursor solution is spray coated on top. The precursor solution contains a fast and slow evaporating solvent as well as the perovskite precursor salts and additives. Next, a gas quenching step is performed by blowing nitrogen with a nitrogen gun onto the sample whereby the fast evaporating solvent is evaporated. This leaves a supersaturated perovskite solution behind in which fast nucleation occurs. Finally an annealing step is performed to allow the slowly evaporating solvent to evaporate and perovskite grain growth to occur. The result is a compact polycrystalline perovskite film.

Many of the spray coating parameters (such as the distance between the nitrogen gun and the sample, the gas quench pressure, the peroskite precursor solution, ... ) were varied in previous studies performed at EnergyVille. Reproducible perovskite solar cells of 14-16% were achieved when using the best conditions. These devices consisted typically only of 250-400 nm thick perovskite films, which is considered as too thin for optimal performance. Meanwhile, thicker perovskite films were also obtained, but there efficiency was lacking behind. The thicker films had even larger grain sizes, resulting in a lower amount of SRH recombination at grain boundaries. Therefore, both short-circuit current and open-circuit voltage are expected to be higher compared to the thinner films. However, this was not the case because more structural defect, cracks, pinholes and pores were observed which resulted in highly shunted solar cells.

This project tries to look deeper into the perovskite deposition and crystallisation step to better understand the reason for the formation of the defects and holes. The most important parameters in the deposition process will be varied, such as the distance of the gas quench blow and precursor solution, depending on the interest of the candidate. Several batches of Glass|NiO|Pk will be fabricated and characterised in our state-of-the-art thin film solar cell lab environment in EnergyVille 2 (Genk). The film characterisation involves structural, chemical and optoelectronic characterisation techniques such as SEM, XRD, EQE, PL, TRPL, ... Based on these results, perovskite single junction solar cells will be made and in-house record efficiencies regarding spray coated perovskite SJSC could be achieved. Based on the student interest and available time more advanced characterisation or the comparison with spray coating of perovskite for tandem solar cells can be explored as well. The project involves layer as well as device fabrication, characterization and data interpretation. The student will join the highly international and skilled perovskite team at EnergyVille. It is expected that the student is motivated and can work independently.

Literature spray coated single junction perovskite solar cells developed at EnergyVille:

Silvano, J., Sala, J., Merckx, T., Kuang, Y., Verding, P., D'Haen, J., ... & Deferme, W. (2022). A study of quenching approaches to optimize ultrasonic spray coated perovskite layers scalable for PV. EPJ Photovoltaics, 13, 12.

Silvano, J., Hamtaei, S., Verding, P., Vermang, B., & Deferme, W. (2023). Investigating the Fabrication of Perovskite Solar Cells by Ultrasonic Spray Coating: A Design of Experiments Approach. ACS Applied Energy Materials, 6(14), 7363-7376.

Type of project: Combination of internship and thesis, Thesis

Duration: 6-12 months

Required degree: Master of Engineering Science, Master of Science

Required background: Materials Engineering, Nanoscience & Nanotechnology, Chemistry/Chemical Engineering

Supervising scientist(s): For further information or for application, please contact: Joost Caeyers (Joost.Caeyers@imec.be) and Jessica de Wild (Jessica.deWild@imec.be) and Bart Vermang (Bart.Vermang@imec.be)

Imec allowance will be provided for students studying at a non-Belgian university.