Optical characterization of SiGe/Si superlattices for future 3D gate-all-around devices

Leuven | More than two weeks ago

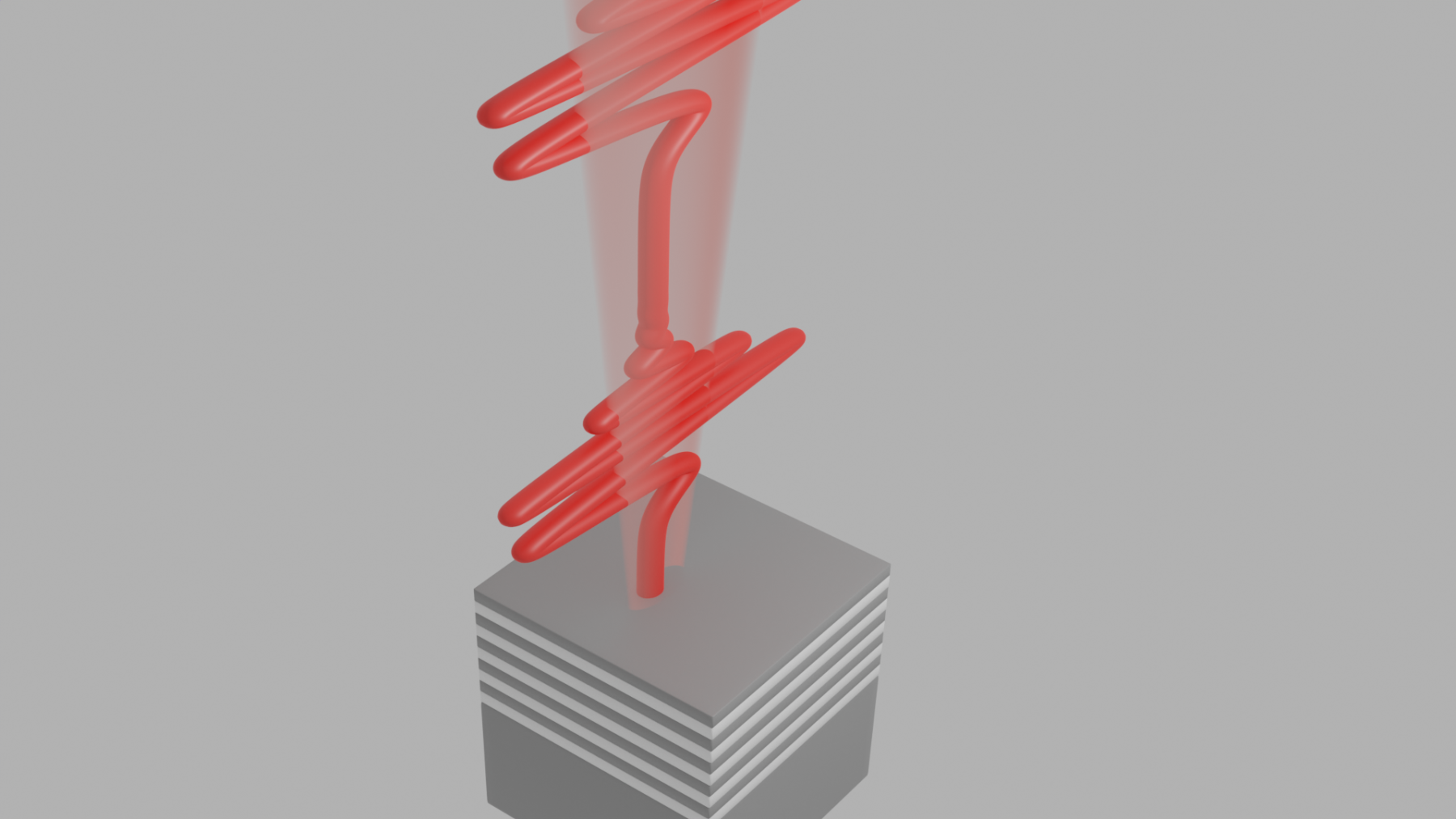

Unravel the geometry of nanoscale 3D devices at the speed of light

As nanoelectronics devices are all transitioning to 3D gate-all-around (GAA) architectures, the relevance of epitaxially grown SiGe/Si superlattices has never been as high. These multilayers are indeed the starting point of nanosheet transistors, wherein the role of the Si layers is no less than being the channels of the future transistor. Albeit later on the technology roadmap, Complementary Field-Effect Transistors (CFET) and 3D Dynamic Random Access Memory (3DDRAM) also rely on SiGe/Si superlattices with, however, a staggeringly increased complexity. All in all, it is therefore crucial to the fast development of these different GAA devices that high-throughput metrology should be available to access geometrical, material and defectivity information about these stacks. To give a few examples, layer thicknesses, Ge concentration profile, strain profile, interface mixing and roughness as well as layer crystallinity all play a critical role in the performance of the final device. Unfortunately, given the lack of optical contrast between SiGe and Si, extracting even basic information such as layer thicknesses is a challenge for most traditional optical techniques. As a result, the industry typically resorts to using slower X-ray metrology, which compromises speed and/or quantity of information.

In this thesis, we aim at reestablishing the value of optical metrology as a reference for GAA devices and develop the high-throughput metrology concepts which semiconductor fabs will need for future logic and memory devices. To serve this purpose, we propose to carry out a fundamental and detailed study of the linear and nonlinear interactions of light with SiGe/Si superlattices with a primary focus on the measurement of the thicknesses of the various layers. Given the sensitivity of light waves to some of the above-mentioned properties, this project will also look opportunistically into the use of optical techniques for measuring these.

In the first phase, the candidate will focus on linear techniques such as reflectometry and ellipsometry to understand the impact of e.g the incident angle, polarization and optical power on the technique sensitivity. Study and proposal of dedicated metrology targets to boost this sensitivity will also be considered. In a second phase, the candidate will explore nonlinear optical technologies, such as Raman spectroscopy, Photoluminescence (PL), spectroscopic pump-probe photoreflectance or Second Harmonic Generation (SHG) to test their ability to extract stack information. Raman spectroscopy and PL should additionally give valuable information on strain and Ge concentrations while SHG should also be a probe of the many SiGe/Si interfaces present in the stack. In a final phase, the candidate will test the hybridization of different linear and/or nonlinear approaches to demonstrate how much information can be extracted from optical measurements only.

This study will rely not only on experiments on tools of the imec cleanroom and various labs but also on numerical simulations to back up and understand his/her experimental findings. Measurements on samples with an increasing complexity (number of layers, variations in the Ge concentrations,...) will help the candidate build progressive understanding about the studied interactions and demonstrate the novel metrology capabilities robustly. The candidate will be part of the advanced patterning metrology group of imec, in close collaboration with the MCA department, which both offer expertise in a multitude of characterization techniques in support of this project. The very close collaboration with the process and integration engineers of imec and its partners warrants direct industrial impact.

Required background: engineering, physics, materials science

Type of work: 60% experimental, 40% modeling

Supervisor: Claudia Fleischmann

Daily advisor: Janusz Bogdanowicz

The reference code for this position is 2024-056. Mention this reference code on your application form.