Reliability of Solid-State-Li-Batteries; Solid Electrolyte Contact Integrity Under Stress

Leuven | More than two weeks ago

Develop next generation reliable and sustainable battery technologies

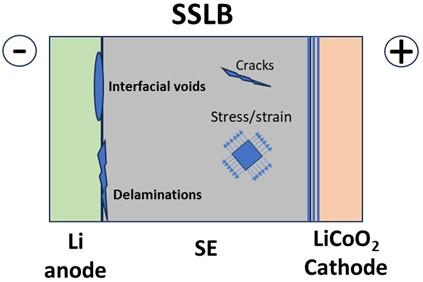

With improvements in ionic conductivity of solid electrolytes (SE), solid-state battery (SSB) technology promises a viable and relatively safer energy storage solution due to absence of flammable organic compounds. SSBs provide high energy densities which can be further increased by using lithium as anode material instead of graphite as in solid-state lithium-ion batteries (SSLBs). In addition, their calendar aging is negligible compared to liquid electrolyte batteries, which is an important sustainability consideration.

Despite numerous advantages, mechanical properties of the material systems in SSLBs, especially elastic, cohesive and interfacial properties of the SE and their impact on the contact integrity of SE with anode and cathode during cyclic deformations, constitute a significant reliability challenge. The cyclic mechanical stresses induced by chemical reactions e.g. intercalation, mismatch of thermal-mechanical properties and also external stack pressures exerted on pouch cells, impact the interfacial contact of SEs. Delaminations, fractures and void formation at the SE interface may lead to deterioration of its contact and thereby battery failure. In addition, tensile and shear stresses in SE can impact its ionic conductivity. Although elastic compliance of SE helps mitigate stresses, excessively soft SEs have been shown to suffer from dendrite penetration. On the other hand, balance of vacancy fluxes at the Li-SE interface induced by the striping current, Li metal creep (induced by stack pressure) and vacancy concentration gradients, has been shown to impact formation and growth of interfacial voids.

Clearly therefore, the mechanical and interfacial properties and also the external stack pressure on pouch cells should be carefully tuned to ensure SSLBs reliability. To this end, in this PhD, a combination of mechanical characterization, constitutive modelling, interface characterization and electro-mechano-diffusion simulations by finite element modelling (FEM) will be employed to optimize the mechanical properties of material systems and stack pressure to improve reliability of SSLBs.

Related reading:

[1] G. Bucci et al. 2017, Mechanical reliability of All-Solid-State Lithium-Ion batteries, ECS meeting abstracts, MA2017-01 124.

[2] H.Yan et al. 2022, How Does the Creep Stress Regulate Void Formation at the Lithium-Solid Electrolyte Interface during Stripping?, Advanced Energy Materials 12(2), 2102283.

[3] I.D. Seymour et al. Suppressing void formation in all-solid-state batteries: the role of interfacial adhesion on alkali metal vacancy transport, Mater. Chem. A, 2021, 9, 19901.

Required background: Master's degree in Engineering, Physics, nanotechnology

Type of work: 10% literature and technological study, 60% numerical modelling, 30% experimental characterization

Supervisor: Philippe Vereecken

Co-supervisor: Houman Zahedmanesh

Daily advisor: Houman Zahedmanesh, Louis De Taeye, Kristof Croes

The reference code for this position is 2024-109. Mention this reference code on your application form.