Infrared and 3D sensing technology

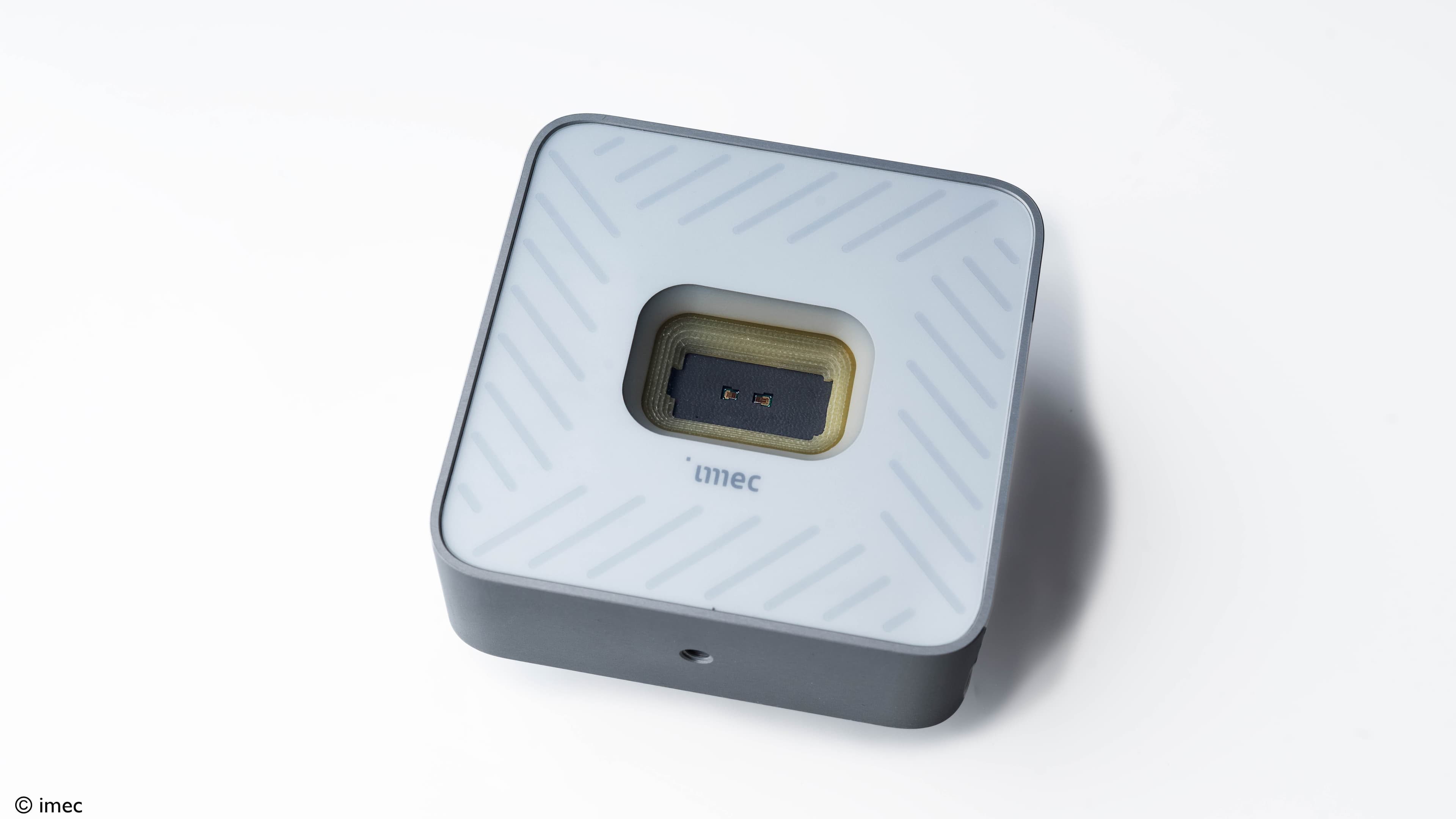

From AR/VR to autonomous driving and face recognition: tomorrow’s consumer applications need affordable imaging technologies that transcend the visible spectrum. That’s why imec’s Pixel Technology Explore activity is looking into innovative routes towards low-cost, high-resolution infrared sensors and 3D imaging.

CMOS technology has made visible imaging compact, low-power and affordable. Just about every smartphone now harbors a digital camera that’s capable of professional photography.

But the needs of the market are changing. Applications such as augmented reality and face recognition, autonomous driving and food scanning require a shift from imaging to sensing – from taking a picture to acquiring information.

The challenge is to bring these new imaging applications within reach of the consumer technology market, by lowering their cost without compromising their resolution. This is the goal of imec’s Pixel Technology Explore research activities, which break new ground in NIR/SWIR sensing and 3D imaging.

Imec intends to develop technologies for companies with a roadmap in innovative image sensors, cameras and smart imaging applications.

Near-infrared (NIR) and short-wave infrared (SWIR) sensing technology

The sensitivity range of silicon-based sensors is fundamentally limited to below 1100 nm. That’s why infrared imaging has been dominated by III-V detectors that are flip-chip-bonded to silicon readout circuits. This both drives up the costs and limits the pixel pitch and resolution.

The Pixel Technology Explore activity is looking at two methods for cost-effective uncooled IR detection:

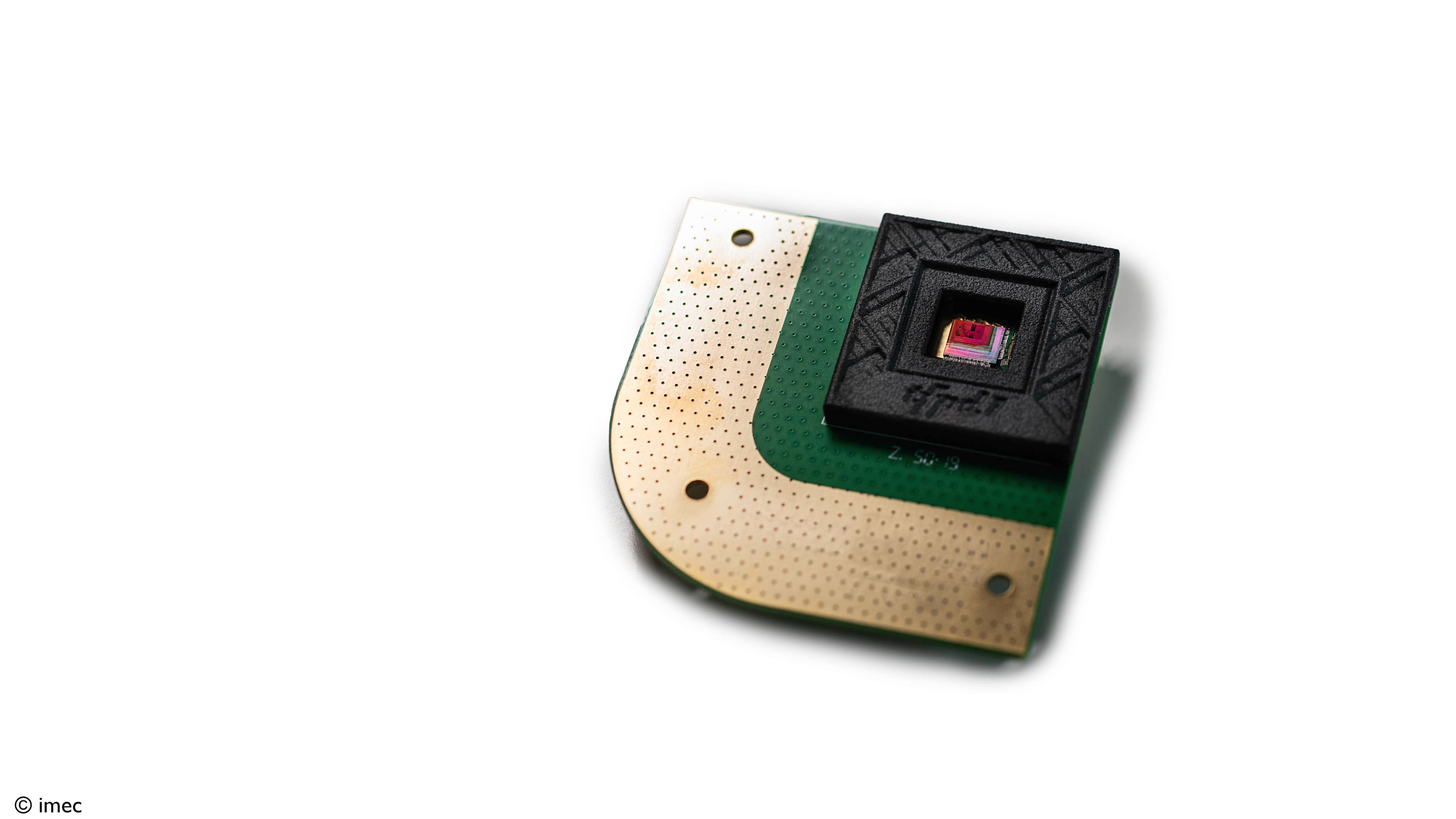

- thin film on silicon – Materials such as organic and colloidal quantum dots offer low-cost synthesis, compatibility with a variety of substrates and processing feasibility on a large area. This article gives you an in-depth view.

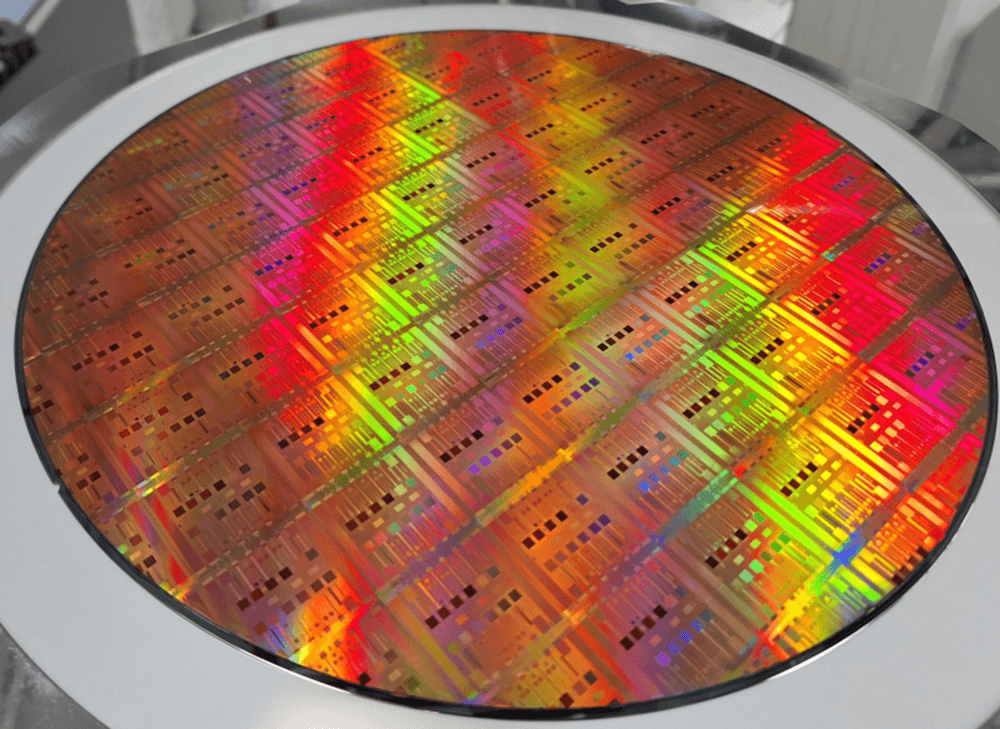

- hybrid infrared imagers – Both III-V hetero-epitaxy on silicon and III-V material transfer on silicon are compatible with processing in a silicon wafer fab and reduce the manufacturing costs of IR sensors.

In-depth article: pioneering advances in semiconductor design for sensing light beyond the visible

2024 press release: Imec and partners unveil SWIR sensor with lead-free quantum dot photodiodes

Watch this demonstration of SWIR imaging. The imec QDPD camera captures the image through the silicon wafer:

Historic overview of imec's research on the use of thin-film photodector (TFPD) technology to enable infrared imaging.

Program tracks of imec's research into manufacturable TFPD sensors.

Silicon-based pixels for 3D sensing

Making use of the third dimension is another way of extending picture content beyond visible photography. For 3D sensing, imec is exploring these research avenues:

- IR laser dot projection – This is addressed by the research topics above that look into uncooled IR detection.

- Continuous Wave (indirect) Time-of-Flight (CW-ToF) – This also relies on an NIR laser pulse but measures the reflected light phase difference within each pixel to get access to distance.

- Direct Time-of-Flight (D-ToF) – This combines an NIR laser pulse with high speed Single Photon Avalanche Diodes (SPAD) that measure the time for a photon to travel between the laser source and the imager.

Want to become our partner in developing new infrared sensing technologies?

As our partner in the Pixel Technology Explore activity, you’re provided with:

- TCAD/optical simulations and pixel architectures

- device demonstrators with analog readout

- process integration at die and wafer level (200/300 mm)

- PCM testing and pixel characterization (PTC, QE, MTF, ...)

- material characterization (TEM, SEM, AFM, ...)

We can also assist you with the development of prototypes. Here, you can take advantage of imec’s unique combination of expertise regarding imaging R&D – from material research all the way up to camera integration.

Imec not only helps you to address technological challenges. Thanks to our thorough knowledge of the industry, we function as your full-fledged strategic partner – right down to venturing support.

Click the button below to get in touch.

Links

- Leaflet: Thin-film infrared imagers

- Press release: Imec Presents a Thin-Film Short-Wave-InfraRed Image Sensor with Sub-2µm Pixel Pitch

- Press release: Imec reports monolithic thin-film image sensor for the SWIR range with record pixel density

- Article: SWIR cost cut: Imec achieves 1.82µm pixels

- Article: Building low-cost infrared sensors with sub-micron films (registration required)

- Article: Make smartphones and autonomous vehicles see the impossible

- Blogpost: Imec PbS QD photodiodes for CMOS integration

- Blogpost: Imec Quantum Dot Sensor