Silicon nitride applications

Tap into imec’s silicon nitride-based photonics platform to enable a wide variety of novel applications.

Silicon nitride (SiN) is the ideal platform for a growing number of photonic integrated circuit (PIC) applications. This page gives you an overview of some of the most promising ones.

Want to put one of these silicon nitride applications into practice? Imec’s SiN pilot line supports you from prototyping toward low- and high-volume manufacturing.

Communication

A silicon nitride platform with distinct features such as tight process control (1-nm thickness control over full 200-mm wafer), CMOS compatibility, low propagation loss, and high-power handling is the perfect environment for developing devices in the communication domain. For example:

- A low-loss silicon nitride interposer chip can function as a wavelength multiplexer that filters and interfaces between a core photonic chip and fiber or other chips.

- Silicon nitride can be used to achieve a long delay line and high-power capability in an optical beamforming network configuration for microwave photonics – used in applications such as 5G and optical satellite communication.

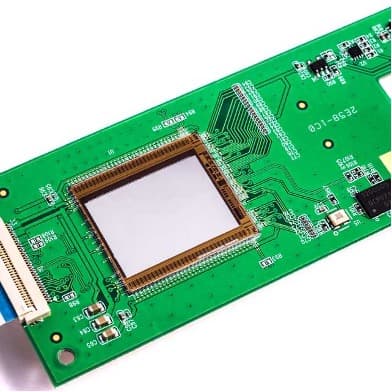

Photonics transceiver prototype

The transparency of a silicon nitride platform covers a wide spectrum, including the telecom/datacom window (1310 nm and 1550 nm). Imec’s CMOS-compatible 200-mm/300-mm silicon nitride technology enables communication companies to integrate their silicon photonic and indium phosphide (InP) technologies in a hybrid approach for applications that require 100 G, 400 G, and beyond.

Here are some of the building blocks they can use:

- waveguides

- ring resonators

- array wave grating (AWG)

- focusing elements

Imec’s 200-mm and 300-mm pilot line supports the development of reliable and scalable products – from prototyping to high-volume manufacturing. It’s already being used by big players in markets from data centers to long-reach telecom.

Key benefits of imec’s silicon nitride platform for the development of communication applications:

- wafer-scale manufacturing technology: 200-mm wafer run

- tight process control over full wafer: 1-nm thickness control

- extremely low propagation loss: 0.3 dB/cm down to a few dB/m

- high-power handling to eliminate nonlinearity issues

- high tolerance to thermal variation of the environment

Quantum applications

Quantum key distribution, quantum computing, and quantum sensing are no longer distant dreams. Groundbreaking technological approaches make it possible to deliver the intrinsic security, ultra-fast calculation, and quantum limit sensing needed for these applications.

Recently, key entities in Europe, the United States and China announced programs promoting quantum technology research, thus demonstrating that quantum is becoming a strategic technology for applications such as ultra-secure communications, super-fast computing and ultra-sensitive sensors.

Quantum photonics is one of the most promising routes towards quantum technology. However, it still faces major challenges:

- Because every photon is counted in the quantum domain, you need an extremely low-loss photonic circuit with low-phase noise distribution.

- Quantum devices need to scale to large systems to be practical for real-life use cases. Without a highly integrated platform, this will lead to bulkiness and high optical loss.

Both of these challenges can be overcome using imec’s 200-mm/300-mm silicon nitride platform for building quantum building blocks such as:

- low-loss waveguides: from visible to SWIR

- high-Q ring resonators

- efficient phase shifting

- MZ interferometer

- comb laser source

- super continuum generation

Key benefits of imec’s silicon nitride platform for the development of quantum applications:

- wafer-scale manufacturing technology

- wide wavelength transparency window: visible to SWIR

- extremely low propagation loss: 0.3 dB/cm down to a few dB/m

- high-power handling to eliminate nonlinearity issues

- high tolerance to thermal variation of the environment

High-performance light sources

Photonic technology is used in a growing number of market domains and end-user products such as spectroscopy, ranging, quantum computing, communicating, and sensing. This also increases the need for high-performance laser sources. To realize them, the hybrid integration of III-V (InP, GaAs) dies with SiN cavities combines the best of both technologies.

Some examples of such promising hybrid integrations are mode-locked lasers with high repetition rates, tunable low-linewidth lasers, multi-wavelength visible laser sources and high-power/low-noise single-mode lasers. Imec, its associated labs at Ghent university and commercial customers have demonstrated many of these with state-of-the-art performance.

Key benefits of imec’s silicon nitride platform for the development of high-performance light sources:

- low-loss interface for coupling to InP/GaAs chips

- low-cost, wafer-scale manufacturing technology

- extremely low propagation loss (0.3 dB/cm down to 2 dB/m)

- high-power handling to eliminate nonlinearity issues

- high tolerance to thermal variations of the environment

Biophotonics

Imec’s low-loss and stable SiN platform enables the development of extremely sensitive, low-cost and disposable solutions for sensing and biophotonic applications in industries such as food, medical tools and life sciences. Dedicated runs for visible applications could be setup according to your specifications and requirements, since the platform is fully flexible in term of layers and materials (SiO, metal, ...)

Our integrated photonic platform allows flexible development and optimization of technology stacks – with considerable freedom when it comes to materials and designs. The evanescent tail of the guided modes can efficiently excite Raman-active molecules that are in the cladding of a sensor. Many spectrometers – both interferometer- and ring-resonator-based – have been demonstrated in silicon nitride technology.

Imec’s on-chip solution for Raman spectroscopy.

Our experts can guide the custom development of your biophotonic application.

Optical beamforming

Optical communication is already well-established and widely deployed within the internet backbone. With customized photonic technology and modified circuit design, it’s now ready to equally prove its use for other applications, such as:

- Autonomous vehicles that need long-range and high-resolution sensing mechanisms.

- 5G networks and high-resolution mechanisms that use microwave photonics to establish flexible and high-bandwidth directional communication links.

- Satellite and ground remote links that rely on high-data-rate and secure free-space optical communication.

- Accurate diagnostic and scanning tools that need novel imaging technologies.

All these applications need an optical beamforming network to non-mechanically steer, shape and focus light. Thanks to its low loss and high-power handling, the silicon nitride platform is ideal to accomplish this.

Gas sensing

Most gases show strong absorption peaks in the infrared wavelength range. Those can be used as unambiguous fingerprints by compact and low-cost sensing applications, for instance for:

- freshness analysis in the food industry, such as fruit and meat

- environmental analysis

- industrial pollution analysis

Key benefits of imec’s silicon nitride platform for the development of gas sensing applications:

- waveguiding opening process to expose the optical field to its surroundings

- wide spectrum ranging: from 400 up to 2000 nm and beyond

- low-cost, wafer-scale manufacturing technology

- extremely low propagation loss: 0.3 dB/cm down to a few dB/m

- high-power handling to eliminate nonlinearity issues

- high tolerance to thermal variation of the environment