Programmable droplet processor

Imec’s programmable droplet processor allows steering millions of droplets at pixel level, enabling fully automated enrichment, purification, and separation workflows through programmable droplet interactions.

A droplet processor is a microfluidic device that can generate, move, merge, and split tiny droplets in a highly controlled and programmable way.

By manipulating droplets instead of bulk fluids, these systems enable precise handling of samples for complex biochemical assays without the need for pumps or valves. Application fields include:

- Proteomics and genomics workflows

- Single-cell editing and multi-omics

- Drug discovery and development

- Diagnostic assays and biomarker analysis

- Automated sample preparation in pharmaceutical research

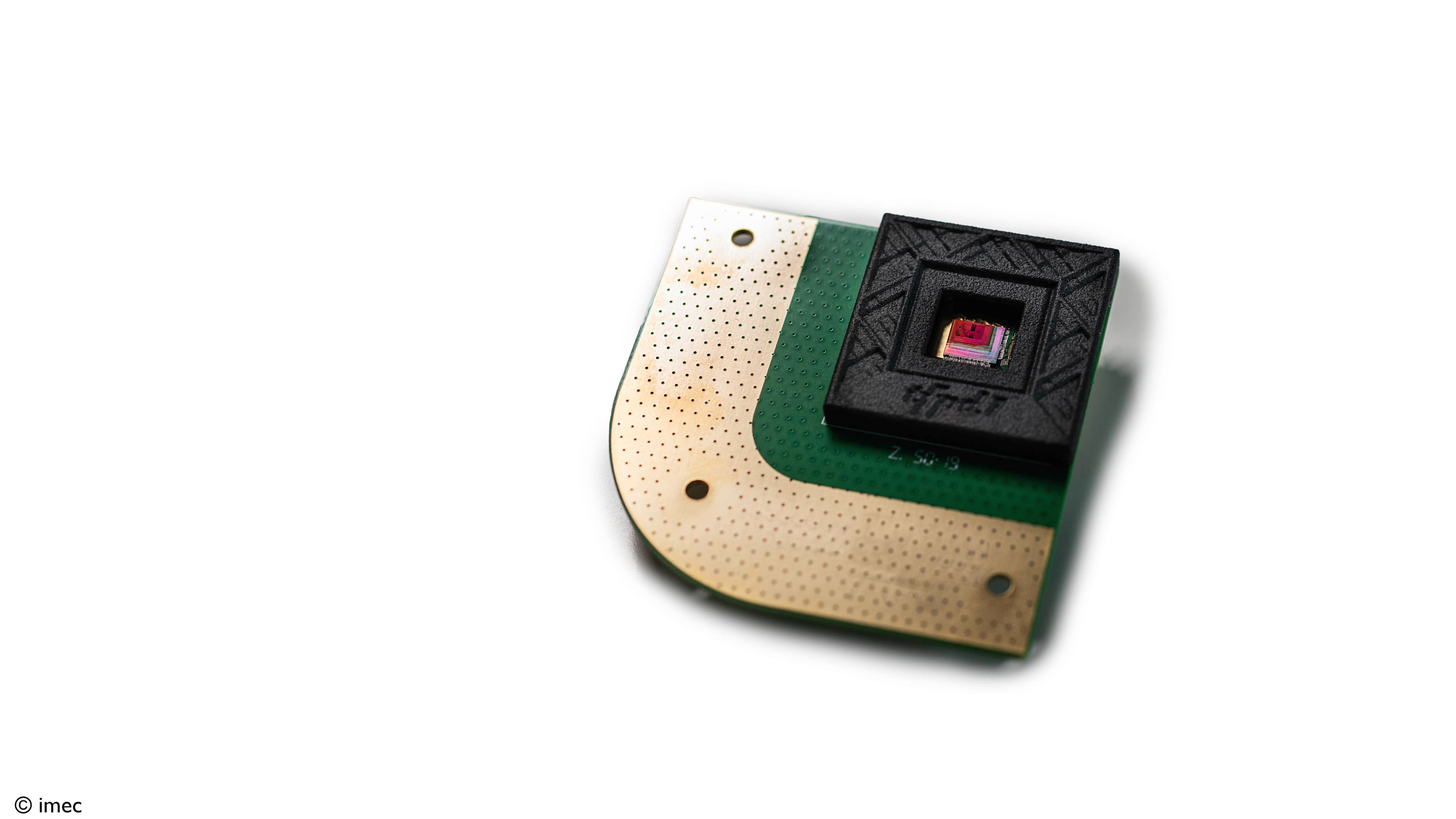

Integrated programmable droplet processor

Imec developed and fabricated a programmable droplet processor (PDP) by combining driving electronics – based on silicon CMOS or thin-film transistor (TFT) technology – and microfluidics with micro-electrode arrays and coating chemistry.

This compact design enables to steer millions of droplets with pixel-level resolution, while also detecting droplet occupation and behavior.

Left: Programmable droplet processor concept (top view); Right: Programmable actuation of suspension droplets

Fabricated programmable droplet processor devices offering a reliable and high-throughput solution for integrated sample prep and analysis assays in e.g., proteomics.

Imec’s technology manipulates droplets in suspension, in contrast to full droplet-device contact in conventional electrowetting on dielectric (EWOD) technologies. Therefore, the dielectric breakdown, biofouling and actuation reliability problems commonly associated with the classical EWOD technology are prevented.

The programmable droplet processor works in a very versatile manner, so that the same hardware can be programmed and adapted to different assays. It allows for easy fluidic handling automation, signal digitization, and high-volume manufacturing for multiple applications.

Left: The moment before two droplets merge. Right: The exponential protein dilution by repeated droplet merging and splitting. The measured protein concentrations match well the designed concentrations in the dilution series.

Work with us

Working with imec means gaining access to a flexible, end-to-end innovation pipeline tailored to your needs. Whether you're exploring a new concept or scaling toward production, we offer multiple engagement models – from intake conversations and concept design to feasibility studies, proof-of-concept development, and prototype manufacturing, to low- and high-volume production.

Click the contact button below to set up a meeting with our team.