Advanced patterning and key process steps

Imec and its partners are working on the improved tools and processes that are indispensable for the advancement of consecutive technology nodes.

Imec works with the world’s leading equipment and material suppliers to develop the most advanced patterning techniques. We combine:

- advanced imaging

- novel patterning materials

- new etch capabilities

- state-of-the-art metrology

These tools and techniques are available in imec’s advanced 300mm cleanroom, resulting in a unique, vendor-neutral lab where the processes for next-generation logic and memory circuits are developed and perfected.

2026 press release: Imec unlocks lever for EUV dose reduction

Do you develop patterning tools, resist chemicals, semiconductor materials, analysis software, semiconductor process technology tools? Or are you perfecting advanced process steps for next technology nodes? Then you’re sure to benefit from imec’s ecosystem, cleanroom and many collaboration options.

Advanced lithography

In the frame of the Advanced Patterning Center collaboration with ASML, we’re developing next-generation EUV patterning solutions while accelerating the industrialization of EUV lithography by pro-actively analyzing and solving technical challenges related to stochastic defects, reliability and yield.

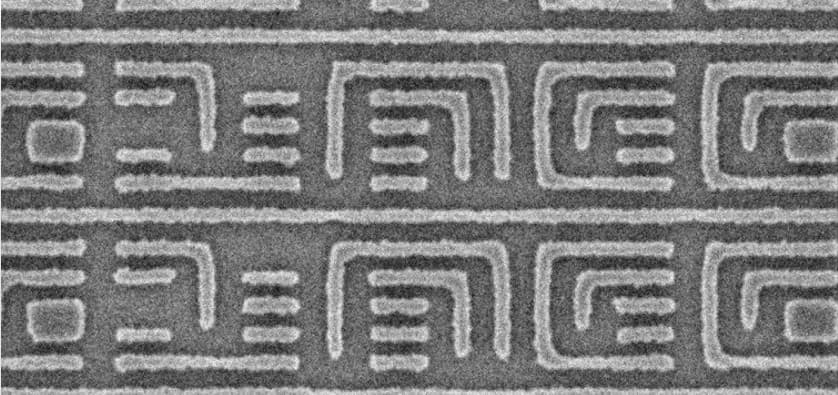

28nm contact holes, obtained on a 0.33NA NXE:3400 full field scanner

To help do that, we’ve set up the AttoLab, where we can image at high-NA EUV dimensions and study EUV photon absorption and subsequent ionization processes at unprecedented timescales from attoseconds to picoseconds.

High NA EUV lithography: launching the industry into the angstrom era

High NA EUV lithography is crucial to extend the logic and memory technology roadmaps into sub-2nm territory.

The case for High NA EUV: unlocking the next era of chip manufacturing

Imec plays a key role in the accelerated adoption of High NA for mass manufacturing. Its pre-competitive research program brings together over 50 partners, from chip manufacturers to equipment/material suppliers and metrology experts sharing risks, costs and IP. They work with imec’s long-time experts on challenges such as mask and imaging optimization, and advanced etch and metrology.

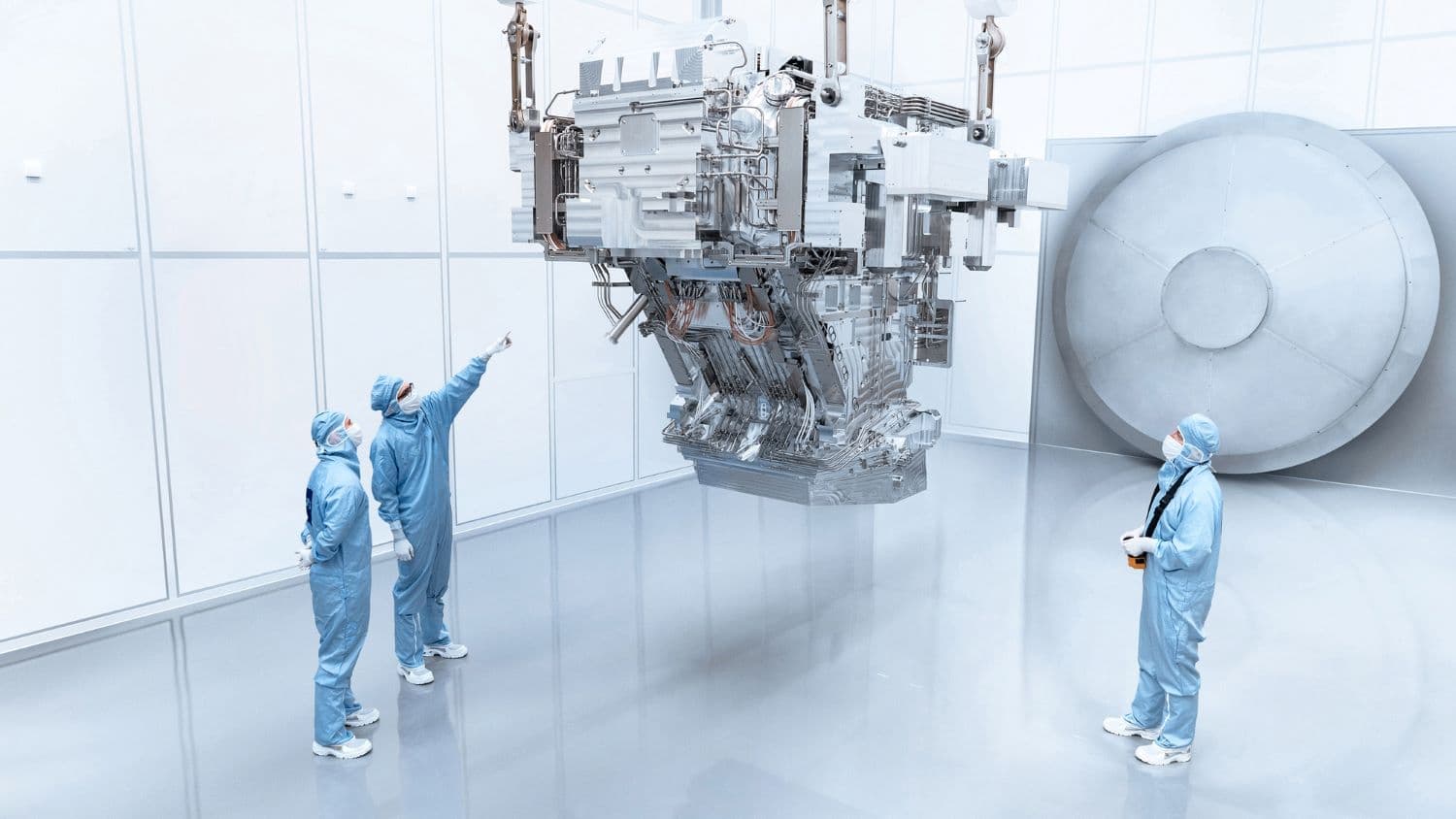

This unmatched access to tools and expertise would be impossible without the unique collaboration between imec and ASML on High NA EUV.

Assembly of a High NA EUV tool in joint imec-ASML High-NA lab at ASML’s headquarters in Veldhoven, the Netherlands. Credit: ASML

In a first phase, this resulted in a joint High NA lab built around the TWINSCAN EXE:5000.

In the next phase, these activities will be ramped up on the next-generation TWINSCAN EXE:5200. This latest High NA tool will be installed as part of the imec pilot line in Leuven, supported by the European NanoIC project.

2024 press release: imec and ASML open joint High NA EUV Lithography Lab

18nm pitch Ru lines obtained with DME after single exposure High NA EUV lithography.

Want to join our research?

Click the button below to get in touch.