WiPeR

Wireless, Pervasive & Reliable Monitoring of Industrial Internet of Things Systems

In industrial settings, condition-based monitoring (CBM) uses sensors in combination with data processing to monitor equipment and industrial processes, boosting product quality and preventing downtime. Working cable-free reduces the sensors’ installation times, cuts installation costs and enables measurements deep inside a machine. But removing network and power cables implies considerable computation and energy management challenges to achieve the sensor data quality and operational reliability that is expected in industry. The WiPeR project will develop an innovative solution for condition-based monitoring that eliminates sensor cables without compromising data quality or reliability.

IoT sensors that take care of themselves

Many companies are looking for cable-free sensors that can deliver high-quality data for at least a maintenance period, ranging from one to 15 years. Cable-free sensors enable a reduction of installation times from days down to minutes. Additionally, they avoid the complex and expensive routing of power and network cables and can therefore be installed deep inside a machine.

Going wireless poses obstacles in industrial settings

Removing network and power cables from sensors is easier said than done. First of all, the available energy via energy harvesting is limited and is constantly changing, and the backup battery must survive stand-alone for up to 15 years to avoid costly on-site maintenance visits. Secondly, low-power wireless networks cannot transmit all the data that is collected by a sensor, and simultaneously signal processing is highly computation (and thus also energy) intensive. Still, state-of-the-art CBM applications call for detailed data input. Furthermore, the wireless network conditions inside a machine are harsh due to magnetic interference, packet reflections, vibrations and extreme temperatures. Yet, CBM applications must reliably receive critical sensor data to achieve quality insights.

Cable-free, longer-lived and rugged

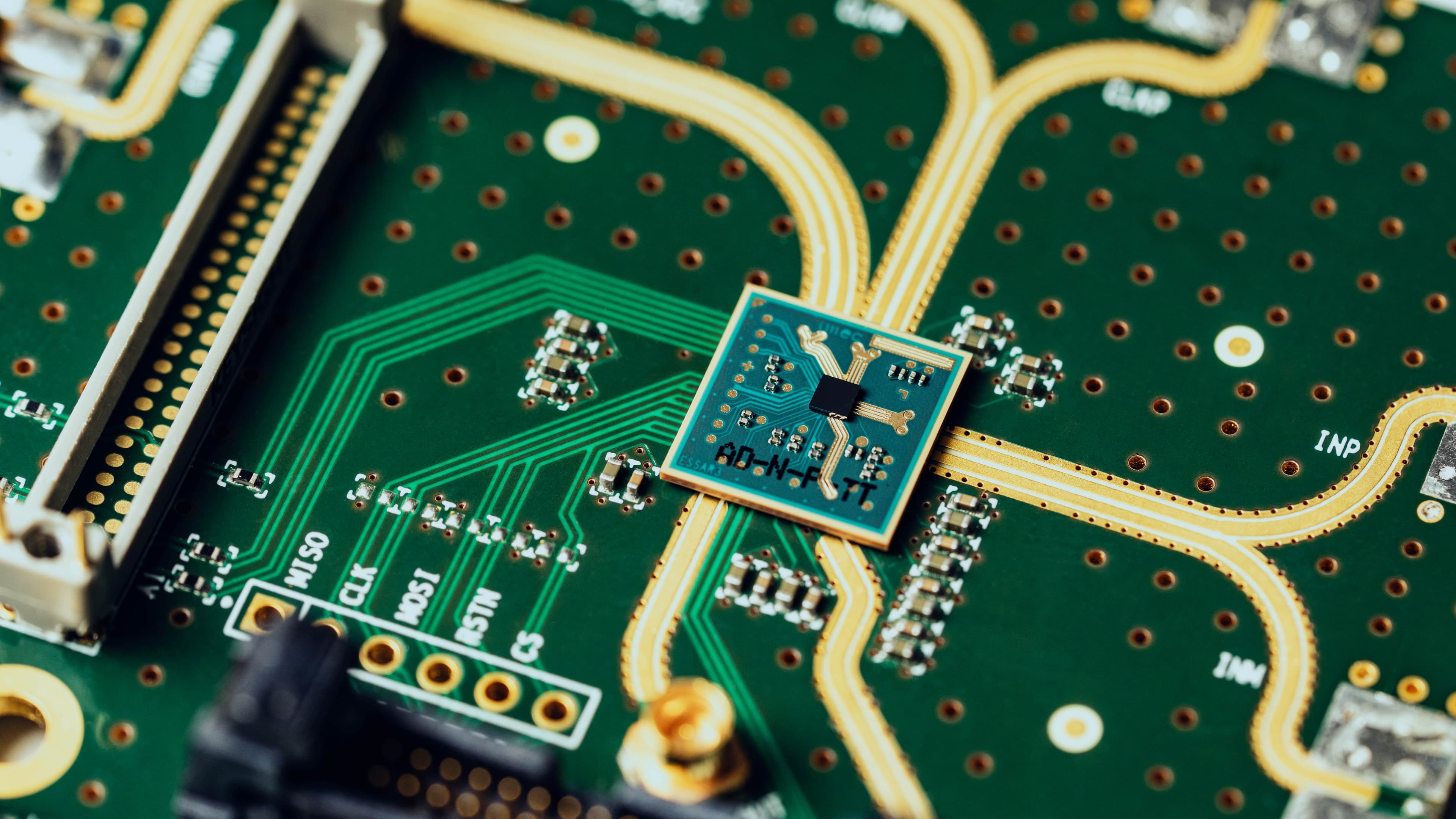

The WiPeR project will create a cable-free IoT sensor solution that addresses these obstacles (cf. the initial hardware prototype shown in the figure). WiPeR will provide sensors with an intelligent hardware/software platform for energy management in order to continuously and automatically guarantee a lifetime of up to 15 years. This solution will reduce the necessary network bandwidth and tailor it to the varying data quality needs of the CBM application. The WiPeR solution will be intensively tested to ensure reliable behavior under various operational conditions (e.g. vibrations and shocks, magnetic fields, heat, moisture and dust), both in the lab and in real-life industrial settings provided by the industry partners. Industry will benefit from the WiPeR technology that improves CBM by collecting high-quality, in-machine sensor data, while reducing the cost of installing and maintaining sensors.

“The WiPeR project will develop an innovative solution for condition-based monitoring that eliminates sensor power and network cables without compromising data quality or reliability.”

Video

WiPeR

Wireless, Pervasive & Reliable Monitoring of Industrial Internet of Things Systems

WiPer is an imec.icon research project funded by imec and Agentschap innoveren & ondernemen.

It started on 01.10.2020 and ended 31.12.2022.

Project information

Industry

- Televic Rail

- Bekaert

- VersaSense

- Umicore Hoboken

Research

- imec - DistriNet - KU Leuven

- imec - EA

Contact

- Project lead: Steven Lauwereins

- Research lead: Danny Hughes

- Proposal Manager: Sam Michiels

- Innovation manager: Eric Moons