ANALYST PV

IntegrAted seNsors and dAta analYSis fault detecTion tools for PV plants

Modern photovoltaic (PV) technologies are highly efficient and productive and can last up to 25 years and more. However, continuous maintenance is needed to keep them operating at top capacity. An estimated 30% of PV plants underperform, and current maintenance practices fall short in reliably identifying faults in PV equipment.

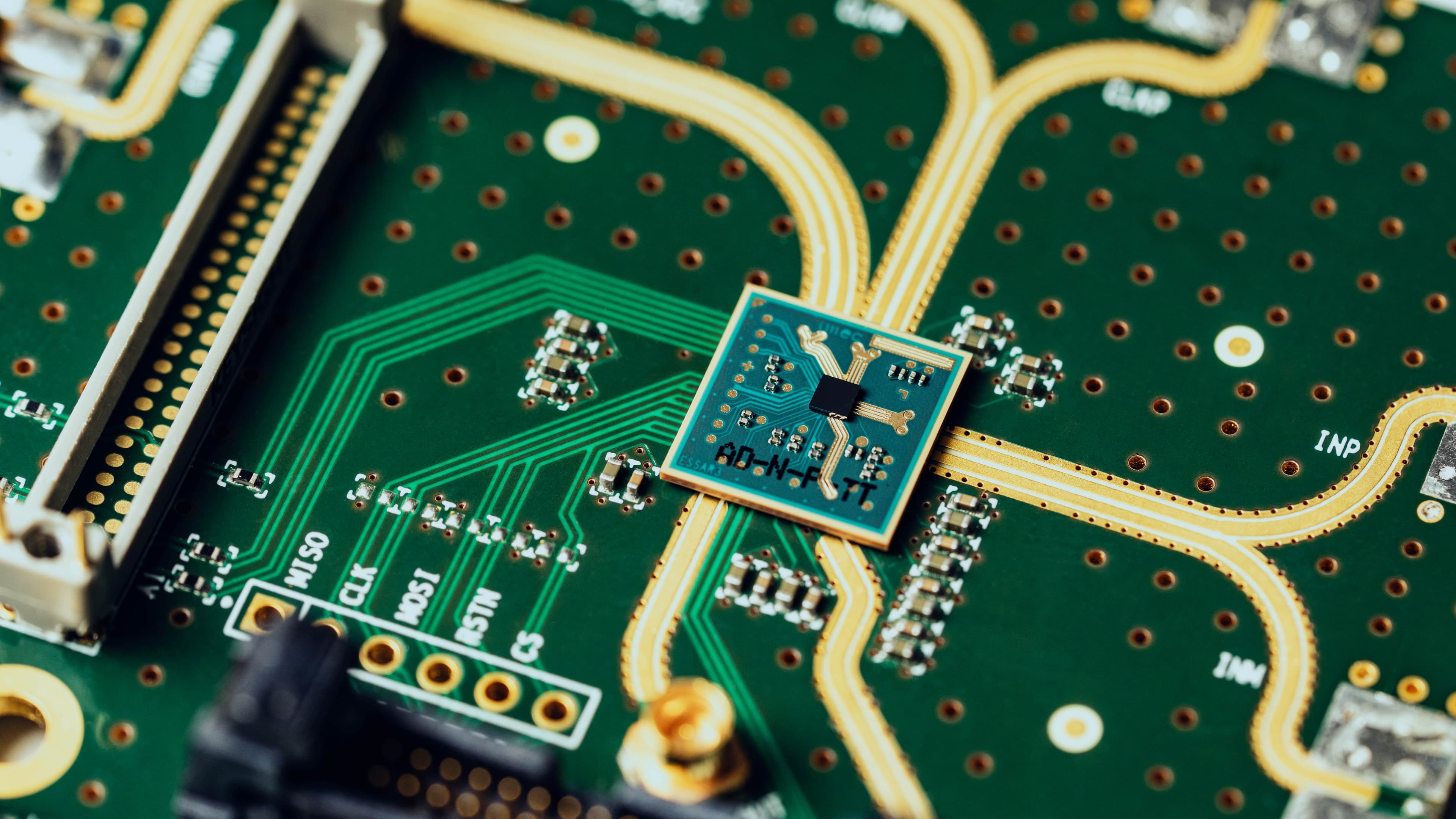

The ANALYST PV consortium will develop a fault diagnosis framework that relies on Internet of Things (IoT) sensors, AI-enabled root cause analysis and automatic image analysis. The proof of concept will be used to simplify practices for preventative PV asset management using the power of data.

Current PV monitoring systems fall short

Photovoltaic technology is a necessary driver of society’s transition toward fully renewable energy sources. Combined, global PV power generation capacity is predicted to reach 1 TW by 2022 compared to 500 GW of total installed capacity in 2019. PV equipment requires a large up-front investment that companies expect to recoup over the plants’ 25-year lifespans. However, a large portion of existing PV plants underperform, potentially because current O&M practices and PV monitoring systems fail to reliably identify problems. As a result, maximizing return-on-investment requires a new approach to PV asset management.

The power of automation and machine learning

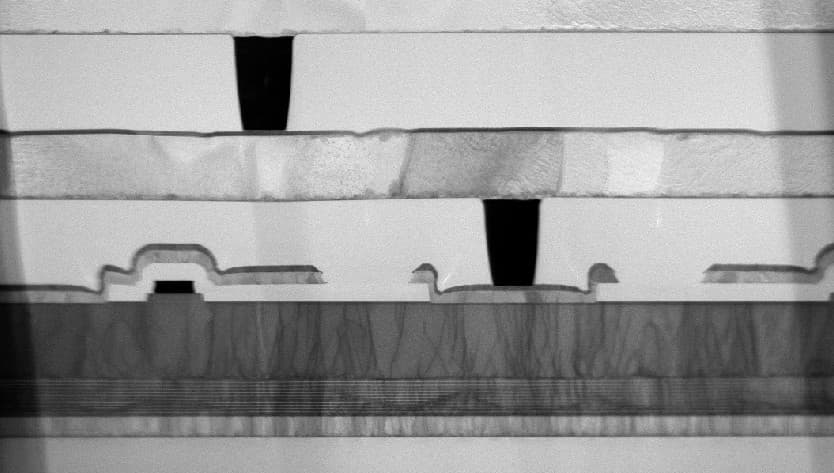

Most PV monitoring and maintenance systems continuously measure the performance of PV cells, but their resolution is too low to identify exactly where the power losses originate. Instead, they rely on manually entered data, which is a time-consuming activity and prone to errors from misconfiguration. Aerial infrared scans performed by drones are also used to gather additional information about PV cells, but current image analysis algorithms generate many false positives.

These shortcomings offer opportunities in the development of a self-learning continuous monitoring solution with high spatial resolution based on data from IoT sensors and the fusion of regular and infrared images.

A digital twin approach that fuses sensor and image data

The ANALYST PV consortium is made up of partners that cover the entire PV value chain, and benefit from imec’s expertise in detection and analysis algorithms. The consortium will accomplish 4 innovation goals:

- Use machine learning to develop an automated digital twin of the PV asset to serve as the basis of a rapid fault detection system.

- Create an automated, efficient and reliable, trustworthy PV fault detection algorithm.

- Validate and measure the benefits of the new framework.

- Link framework observations with decision-making by providing insights into PV equipment lifespan, power and revenue loss and possible repair/replacement actions.

Efficient asset performance management to reduce labor costs and increase revenue’

The framework developed by the ANALYST PV consortium will significantly reduce manual intervention and man hours spent on PV asset management. It will also help maximize the output of PV plants by automating the processes involved in the detection and amelioration of faults.

“The ANALYST PV project will develop a fault diagnosis framework that relies on IoT sensors, AI-enabled root cause analysis and automatic image analysis. The ultimate goal is to optimize photovoltaic asset management and performance.”

ANALYST PV

IntegrAted seNsors and dAta analYSis fault detecTion tools for PV plants

ANALYST PV is an imec.icon research project funded by imec, Innoviris and Agentschap Innoveren & Ondernemen.

It started on 01.10.2019 and is set to run until 30.09.2021.

Project information

Industry

Research

- imec – IPI – UGent

- imec – PVMS

Contact

- Project lead: Mauricio Richter

- Research lead: Eszter Voroshazi

- Proposal Manager: Eszter Voroshazi

- Innovation manager: Annelies Vandamme