ELITE

Efficiency-optimized production Lines using industrial Internet of Things Enhancements

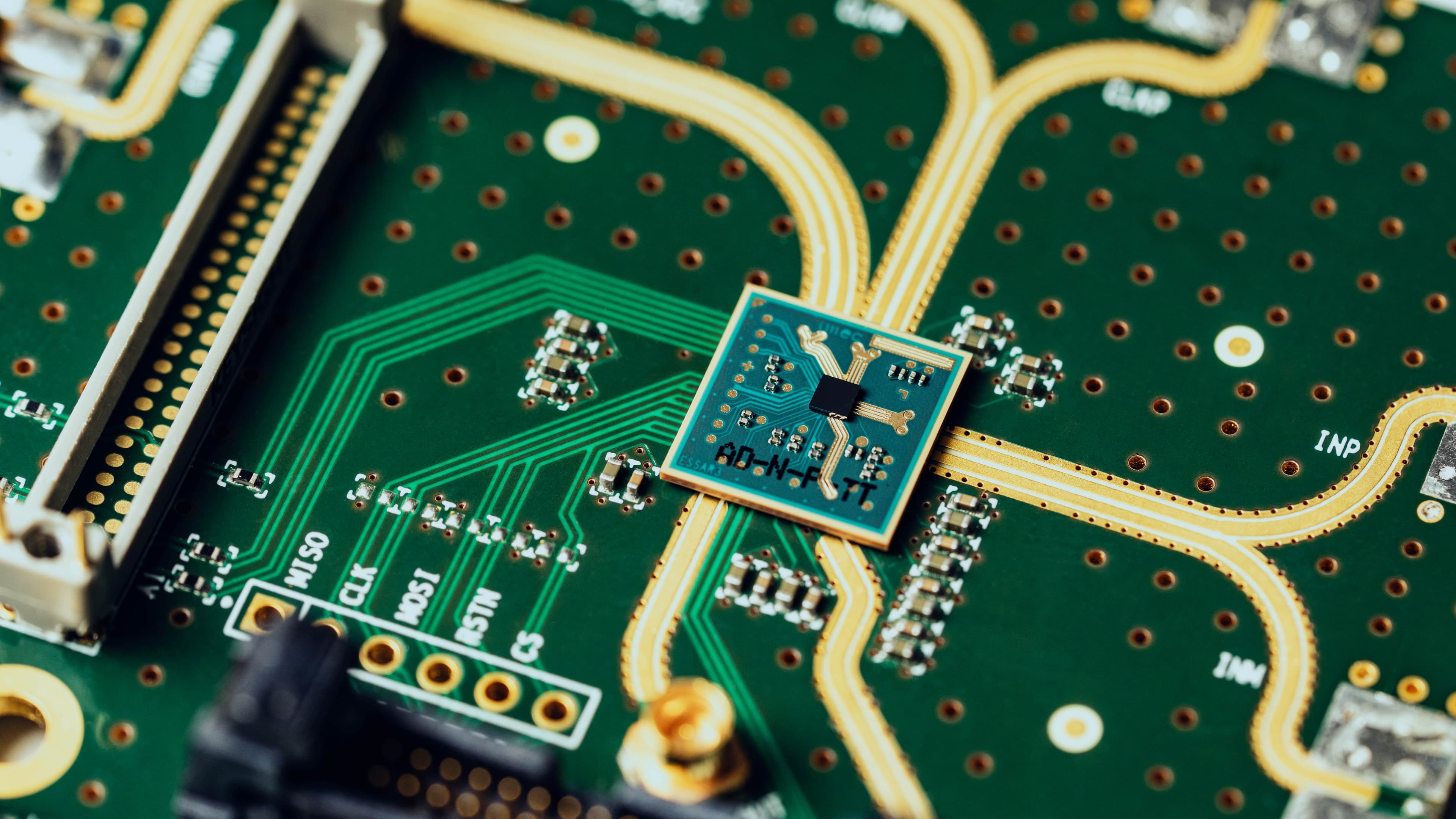

The Internet of Things (IoT), which is the network generated when everyday objects can send and receive data, has the potential to transform production. Data generated by equipment and infrastructure can be used to schedule maintenance, prevent issues and reduce waste. The ELITE project seeks to optimize the management of IoT-generated data to boost the production efficiency of SMEs, resulting in less downtime, streamlined processes and lower energy costs.

IoT technologies bring competitive advantages

In order for companies to remain competitive in the age of Industry 4.0, they must constantly improve the cost efficiency of their operations. Data can have a huge impact on efficiency, but many manufacturers fail to collect it, gather only fragmented information or store it without analyzing it. New IoT technologies for the manufacturing sector may facilitate the easy, low-cost, flexible collection and analysis of production line data. However, parameter measurement, big data management and insight-based production strategies must be explored further within the context of production line efficiency.

End-to-end solution for two production environments

The ELITE consortium features a variety of diverse research and industry players with expertise in plug & play wireless sensors, process control and automation, data analysis and visualization, statistics, predictive analytics and more. They will collaborate to develop an end-to-end production efficiency optimization solution to be implemented at Soubry and Voeders Huys, food product and animal feed manufacturers.

The solution will:

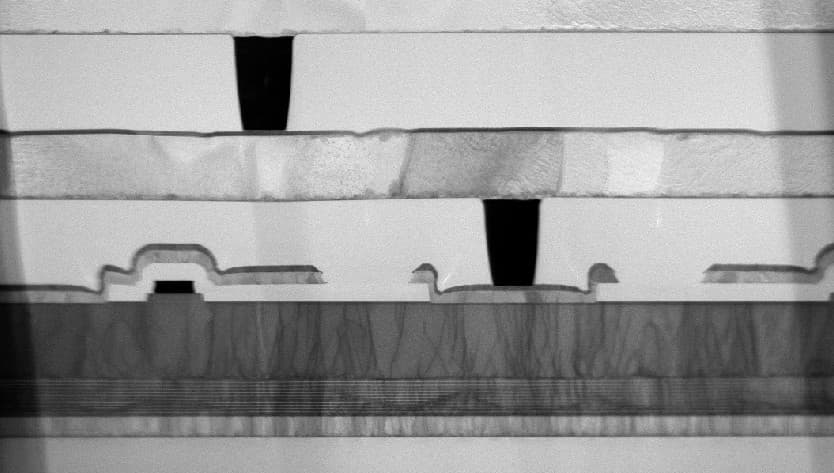

- measure process data cheaply and non-intrusively;

- integrate process data into the existing process management system;

- analyze the data to gain insights useful for operators;

- optimize process parameters and lead to energy-aware scheduling algorithms.

Concrete components and methodologies

The results proposed by the ELITE project will provide manufacturers with more opportunities to reduce costs, boost the performance of their production processes and be more competitive in a global marketplace. Partners will benefit directly by taking advantage of new market segments, offering new products and optimizing their own manufacturing processes.

“The ELITE project seeks to optimize the management of IoT-generated data to boost the production efficiency of SMEs, resulting in less downtime, streamlined processes and lower energy costs.”

ELITE

Efficiency-optimized production Lines using industrial Internet of Things Enhancements.

ELITE is an imec.icon research project funded by Agentschap Innoveren & Ondernemen and imec.

It started on 01.10.2017 and is set to run until 31.12.2019.

Project information

Industry

- Intation

- Trendminer

- Indeff

- Etablissementen Joseph Soubry

- Voeders Huys

Research

- imec - WAVES - UGent

- imec - IDLab - UGent

- Flanders Make

Contact

- Project Lead: Tom Drieman

- Research Lead: Toon De Pessemier

- Innovation Manager: Piet Verhoeve