Currently, volumetric quality control happens sample-based and offline. The lack of in-line solutions causes batches of products to be taken out of the production process as a quality precaution, and as such a significant waste cost occurs in many sectors. To overcome challenges related to process control and false rejects (for which off-line checks are often applied today) iXCon has developed a breakthrough in non-destructive in-line detection of product defects. The solution that was developed for high-throughput, industrial quality control allows for fast 3D volumetric evaluation of each product on the conveyor belt by means of X-ray imaging. The smart combination of flexible hardware and intelligent software has resulted in three successful use cases and a step-up technology for implementation in sectors such as: agro-food, product manufacturing, process monitoring, 3D printed materials etc. While demonstrated with attenuation-based X-ray tomography setups, the technology may in the future also be integrated together with other imaging solutions such as phase-shift X-ray, multispectral, THz…

The outcomes

1. Robotized rooting of agricultural products that have irregular structures - Robovision

Thanks to the ability of verifying the internal structure and quality of flower bulbs, the efficiency of automated plating can be drastically increased, e.g. by eliminating dried-out bulbs and by planting the good seeds with the correct side upward.

2. Internal quality inspection of fresh fruit by 3D non-destructive imaging - MeBioS

Fast 3D volume inspection of whole fruits (pears in this use case) supports the automated sorting after harvesting, leading to more homogeneous batches ánd less waste.

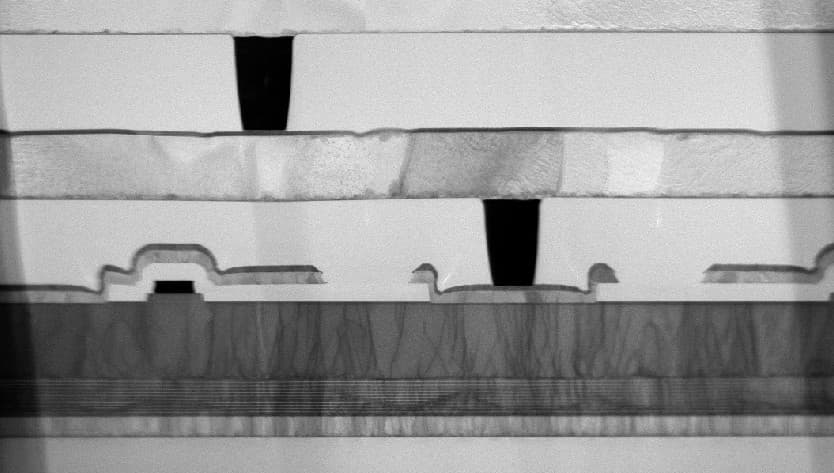

3. Quality control of small medical devices - Terumo

For mass production of medical devices, the technology developed in the iXCon project has proven its capabilities to be used as fast and qualitative inline inspection system. The technology can now be further developed to be added to the various visual-camera inspection techniques already in place.

4. Enabling technologies

A flexible hardware platform speeds up industrial implementation: A dedicated hardware setup has been built which allows three degrees of freedom in the individual movement of source, detector and sample/stage. This is particularly useful in an R&D context or to test a myriad of configurations in the development of a dedicated industrial setup.

Self-learning software decreases ramp-up time: By feeding the software with existing knowledge of the inspected product (material properties, CAD information…), it can self-learn in an automated way and thereby decrease the time that is needed to set-up and validate the detection system for a given industrial application.

Image reconstruction with minimal amount of data allows for realtime in-line monitoring: Thanks to the smart interaction between hardware and software, the technology developed within iXCon allows to reduce the usual amount of up to 1500 scans needed for quality inspection with offline monitoring to only 50 scans or less. This efficiency gain now also allows for realtime in-line monitoring of products passing by on a conveyor belt.

Video

Download leaflet

iXCon

Industrial X-ray CT for high-throughput quality control.

iXCon is an imec.icon research project funded by imec and Agentschap Innoveren & Ondernemen.

It ran from 01.10.2016 until 30.09.2018.

Project information

Industry

- X-Ray Engineering bvba

- Robovision

- Terumo Europe

Research

- UGent - Radiation Physics

- KU Leuven - MeBioS

- imec - Vision Lab - UAntwerpen

Contact

- Project Lead: Denis Van Loo

- Research Lead: Jan De Beenhouwer

- Innovation Manager: Dirk Hamelinck