SloGaN

System and GaN device co-design for fully optimized, efficient GaN-based power systems in a full-chain approach, demonstrated by integrated half-bridge point of load and power supply circuits

The Gallium Nitride (GaN) power market is currently dominated by discrete components. However, to unlock the full potential of fast-switching GaN HEMT technology, inductive parasitics between the gate drivers and power devices in half-bridge circuits need to be reduced. Taking a complete value chain approach, the SloGaN project targeted point of load (PoL) convertor and power supply circuits with fully integrated half-bridge GaN ICs.

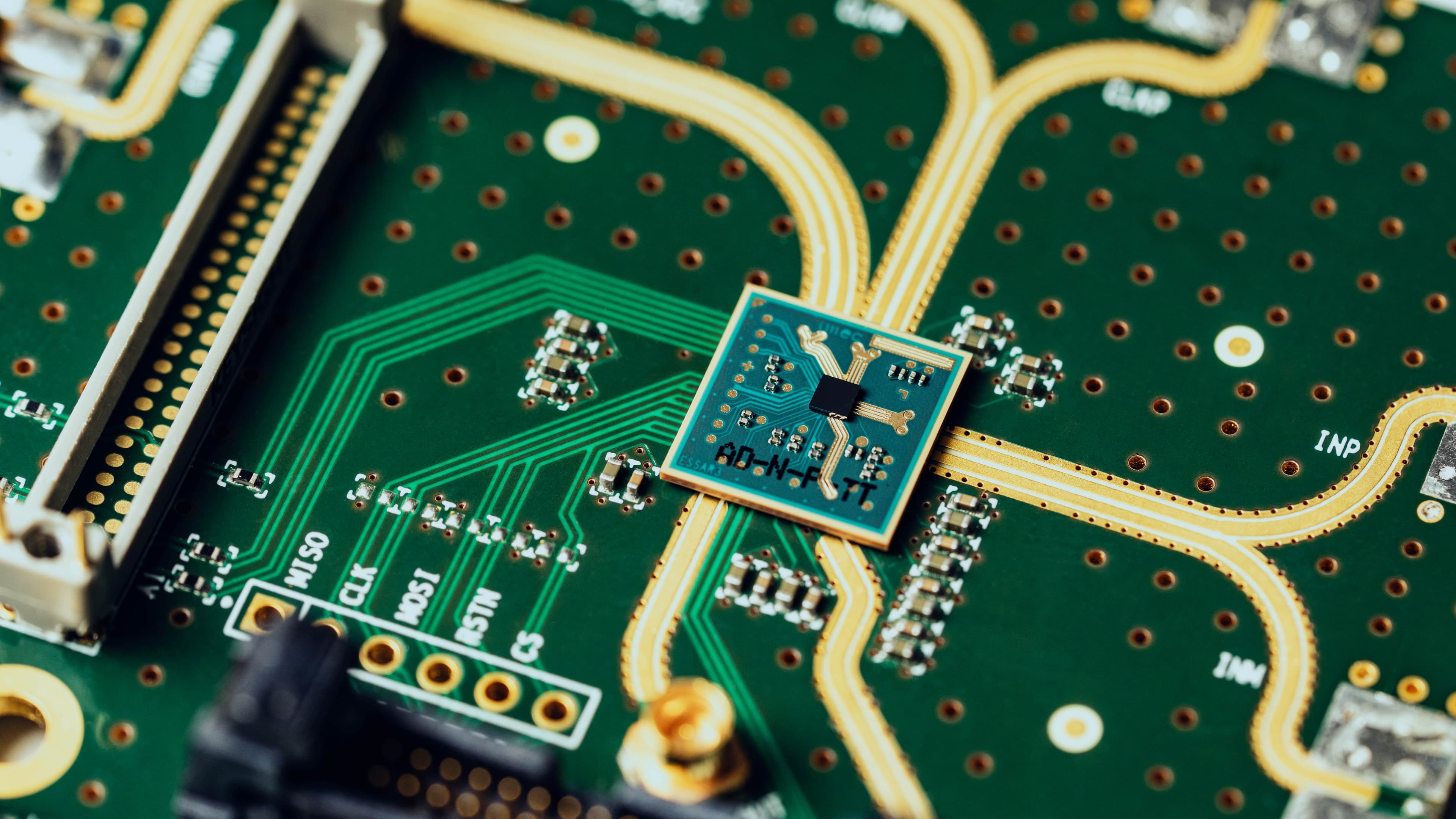

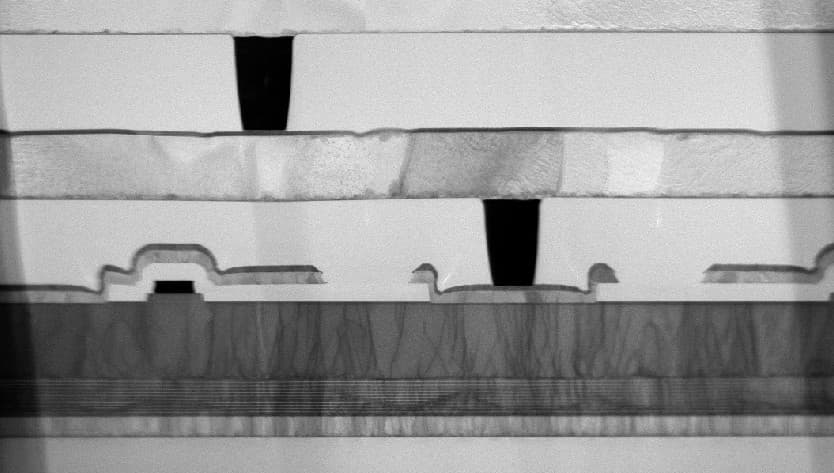

Using imec’s GaN-on-SOI (Silicon on Insulator) process combined with oxide filled deep trench isolation (DTI), the SloGaN project was able to monolithically integrate the two power transistors (high-side and low-side) of a half-bridge along with their respective gate drivers on a single chip. Greatly reducing parasitic inductance while simultaneously cutting the component count. The results were demonstrated in a DC-DC buck converter by end-user Thales Alenia Space Belgium.

The SloGaN approach aimed to set up a complete value chain from GaN substrate fabrication right through to a DC/DC convertor demonstration. This full chain approach, including development of a process design kit (with compact models), GaN power device design based on 2D simulations, and validation of building-block improvements as well as GaN IC design and assembly, allowed the system to be optimized as a whole, rather than in sequential steps.

In particular, the project aimed to:

- develop an updated component roadmap for GaN integrated components (integrated switching poles), producing and validating prototype components

- develop a low loss driver set with built-in isolation fit for (integrated) GaN power components

- improve component-level models: reduced-order (equivalent circuits), thermal and reliability models

- demonstrate a substrate / package, bonding techniques and associated circuit mounting (soldering, sintering) for GaN power stages, aiming at improved thermal paths, thermal resilience, improved reliability and parasitic reduction

- validate the above building-block improvements in several complementary circuit categories representative of multiple applications such as power supplies in a wide voltage/power range, DC-DC interfaces for photovoltaics, batteries, DC-AC interfaces for drives and grid-coupling.

THE OUTCOMES

1. Successful integration

One of the primary goals of the project was to successfully develop and integrate various components on a single die.

- High-side (HS) & low-side (LS) GaN transistors – many other companies and research centers have failed at this step. This is a key asset of imec’s GaN on SOI with DTI isolation between transistors.

- Gate driver - allows fast switching but also prevents parasitic turn on of the opposite side transistor when one (either HS or LS) turns on

- Gate driver voltage regulators - gate structure is known to be fragile with GaN transistors, so any overdrive should be avoided. However, in a fast transient switching system overshoots are difficult to avoid, hence gate voltage control is a key asset.

In addition, IMEC’s GaN-on-SOI process has been improved to avoid deep trench delamination, and a copper (Cu) redistribution layer was developed. Based on the design feedback, the threshold voltage has been reduced by 0.5 Volt.

2. Extending supply chain capabilities

As part of the complete value chain approach, several specific learnings were achieved during the project.

- Magwel’s ptmet tool capability was enhanced to achieve the SloGaN project goals while supporting design activities.

- C-MAC has built tangible know-how of the sintering processes, based on the theoretical research, assembly and testing of demonstrator boards.

- IMEC-EA contributed with modelling tools at die assembly level to provide support to power die assembly designs.

3. Validation and demonstration

The project resulted in the validation and demonstration of a series of power converters designed for different power levels. These were implemented in printed circuit boards (PCBs) which were used to characterize the performance of both the newly developed and reference components. The power efficiency results, demonstrated in a buck DC-DC converter, showed that the integrated half-bridge behaved as well as its discrete-based predecessor. This was a key result, confirming that the integration was successful and that it did not degrade efficiency – meaning that designers can now move away from using discrete components.

SloGan

System Level Optimization of GaN-based power devices.

SloGaN is an imec.icon research project funded by imec, Innoviris and Agentschap Innoveren & Ondernemen.

It started on 01.05.2018 and ran until 30.04.2020.

Project information

Industry

- C-Mac Electromag

- Magwel

- MinDCet

- Thales Alenia Space Belgium

Research

- EA-imec/EnergyVille

- PMST-imec/EnergyVille

- ELECTA - KULeuven

Contact

- Project lead: Marc Fossion

- Research lead: Stefaan Decoutere

- Proposal Manager: Stefaan Decoutere

- Innovation manager: Eric Moons