Metal additive manufacturing is changing the way we design and produce parts for products in aerospace, energy, automotive, medicine, tooling, and other sectors. By melting metal powder using high power lasers, metal 3D printers can rapidly create lightweight and complex objects while using less material.

One of the major challenges with this process is precision control, especially concerning the temperature of the metal. If the metal gets too cold, it will not melt completely; if it gets too hot, we risk damaging the previously printed layers. With 3D metal printers operating at high speeds, such problems are not visible to the human eye until it is too late to intervene and correct them. As a result, roughly 10% of printed parts have to be scrapped due to a low print quality.

While high-speed camera recordings of 3D print jobs have already been used to gain insight into the formation of defects, they have provided only limited benefits to the optimization of the print process. To really overcome the challenges in print quality, we have now built a high-speed visual system that is integrated into the additive manufacturing process, allowing for quick interventions in the printing process to prevent defects.

The goal of the Vision-in-the-Loop project was to prove and demonstrate that metal additive manufacturing can produce parts with a better quality by controlling the print process in real time using a high-speed vision system.

To be able to do this – to close the loop between process monitoring and control – this vision system required advances in:

- high-speed imaging

- real-time video analytics

- the correlation of these analytics to print quality

- real-time 3D printer control

The outcomes

The Vision-in-the-Loop project attained the following achievements:

1. The design and creation of a high-speed camera running at 20,000 frame-per-second

This camera has the ability to change the region of recording for each video frame. This allows focussing the camera on what the printer’s laser is doing regardless of the size of the printed object.

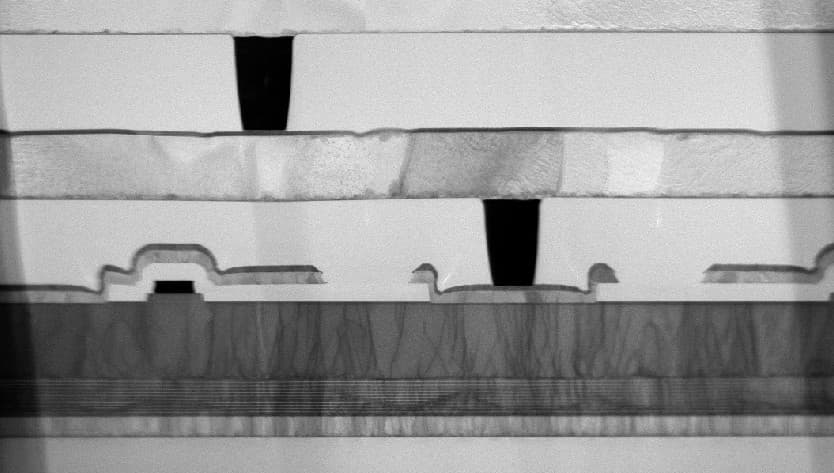

2. The design and creation of new CT image reconstruction algorithms that reduce image scattering artifacts by 92%

This allows detecting printing defects that are smaller than 100 micrometers. These advances in CT imaging provide us with precise measurements of the printing defects that we can then link to the images from the high-speed camera.

3. The design and creation of real-time, AI-based algorithms for the detection of printing defects and the adjustment of the printing process

In particular, new video features were developed to capture the stability of the printing process, a new AI model linked the video features with known defects, and new multi-input, multi-rate control algorithms were designed to convert defect creation probabilities to corrective adjustments in the printer’s laser power. This real-time platform improved the accuracy of defect detection by 42%, and this with a low latency of approximately 1 millisecond. This accuracy and low latency make it possible to correct the laser power in real-time in order to prevent printing defects.

The project partners combined these achievements into a single high-speed vision platform to monitor, analyze, and adjust the printing process in real-time. This platform was the result of all VIL-research and demonstrated that closing the feedback loop from monitoring to control effectively reduced the likelihood of seeing print defects in metal additive manufacturing.

Video

VIL

Vision In the Loop: high-speed image processing for real time control of 3D printers.

VIL is an imec.icon research project funded by imec and Agentschap innoveren & ondernemen.

It started on 01.04.2020 and is set to run until 30.06.2022.

Industry

- AdditiveLab

- Dekimo Products

- Esma NV

- Materialise

Research

- Flanders Make - MaPS - KU Leuven

- imec - IPI - Ugent

- imec - Vision Lab - UA

Contact

- Project lead: Tom Craeghs

- Research lead: Wilfried Philips

- Proposal Manager: Wilfried Philips

- Innovation manager: Annelies Vandamme