Next-generation composite electrode materials for lithium-ion batteries

Hasselt | More than two weeks ago

Powering Tomorrow: Pioneering Next-Gen Materials for Lithium-Ion Batteries at Imec.

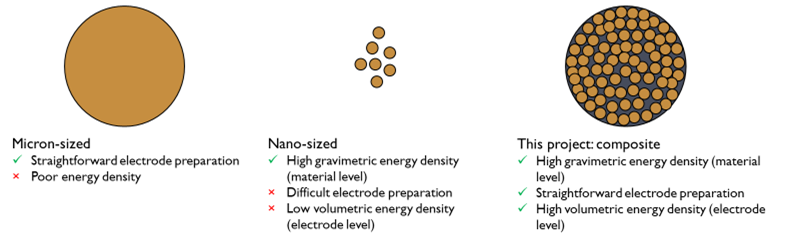

Current state-of-the-art bulk lithium-ion batteries can contain positive electrode materials that operate through the insertion and deinsertion of lithium ions in a transition metal oxide with a layered or a spinel-type structure. However, further improvements in their energy density are expected to be limited because of their moderate operating potential and/or capacity. Therefore, these materials may not be able to meet the ever-increasing need for electrochemical energy storage necessitated by electric mobility applications and renewable but intermittent energy sources. More impressive improvements in energy density may be realized by next-generation positive electrode materials such as advanced polyanion compounds, disordered rock salts, etc. The former material class has a very rigid structure, which endows them with exceptional electrochemical stability. Furthermore, the polyanion groups increase the ionic character of M-O bonds (inductive effect), which increase their operating potential (e.g. >4 V vs Li+/Li). Some polyanion compounds can reversibly extract two lithium ions per metal ion, offering a high theoretical capacity (e.g. >200 mAh g-1). The latter class is cobalt free and can allow fast charging. Therefore, next-generation materials have the potential to offer a very high energy density and/or fast charging. Unfortunately, a common limitation of polyanion compounds is their low electronic (and ionic) conductivity, which significantly hampers their practical energy density. Whereas nano-sizing has been explored as a way to overcome this challenge, this in turn leads to difficulties in electrode preparation and to low volumetric energy densities on electrode level, owing to the low tap density of nano-sized particles.

In this project, we aim to achieve high energy densities at both the material level (gravimetric) and the electrode (volumetric) level. To achieve this goal, we will use chemical synthesis processes for the preparation of nano-sized next-generation positive electrode material particles with high gravimetric energy density. The solution-based nature of these synthesis processes allows a careful control of the phase composition, particle morphology, and size. Subsequently, we will use a spray-based approach to embed the nano-sized particles in a conductive matrix. The type of conductive matrix and the active material/matrix ratio are important parameters to be optimized. The resulting composite particles, with particle size in the micrometer range, will allow straightforward electrode processing and high volumetric energy densities because of their higher tap density. The nano-sized particles and composite particles will be subjected to a comprehensive list of physicochemical and electrochemical characterization techniques. This will allow us to generate fundamental and applied knowledge on the link between the synthesis parameters, physicochemical characteristics, and electrochemical performance of the materials.

Required background: Inorganic Chemistry, Electrochemistry, Materials Science or equivalent

Type of work: 80% experimental, 20% literature

Supervisor: An Hardy

Co-supervisor: Marlies Van Bael

Daily advisor: Dries De Sloovere

The reference code for this position is 2024-097. Mention this reference code on your application form.