AID-WELD

Optimizing Robotic Arc Welding.

Improving weld quality at the source

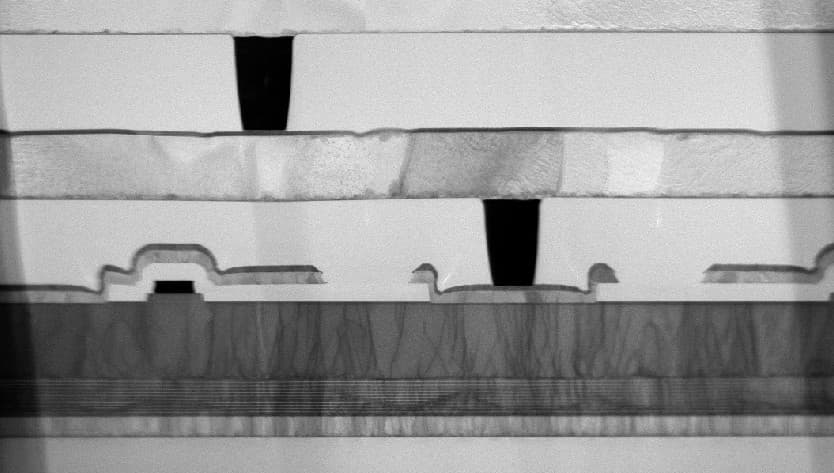

Robotic arc welding is a key fabrication technique for components in the metal processing industry; its use is expected to grow significantly in the coming years. However, due to the complexity of the arc welding process, it inherently produces defects.

Today, weld defects are mainly detected after the production, through manual checks, visual inspection, or non-destructive testing. This timing leads to rework, waste of materials, higher energy use, lost time, and potential safety risks.

A major challenge for the industry, therefore, is to detect the defects earlier, preferably as soon as possible in the production process, in a way that is reliable and cost-effective. However, real-time detection of weld defects is rarely done, mainly because so many factors influence the weld quality, and because the harsh industrial conditions make in-line monitoring difficult.

AID-WELD addresses these challenges by enabling early, in-process detection of weld defects. The goal is to improve production quality and efficiency without disrupting existing production setups.

Innovation beyond the state of the art

Systems for inline monitoring of welding already exist, but they are largely limited to laboratory environments and often rely on a single type of sensor. In real fabrication conditions, these approaches struggle with noise, heat, and changing process parameters. AID-WELD aims to surpass current monitoring solutions by delivering a complete, real-time quality monitoring system designed for industrial deployment.

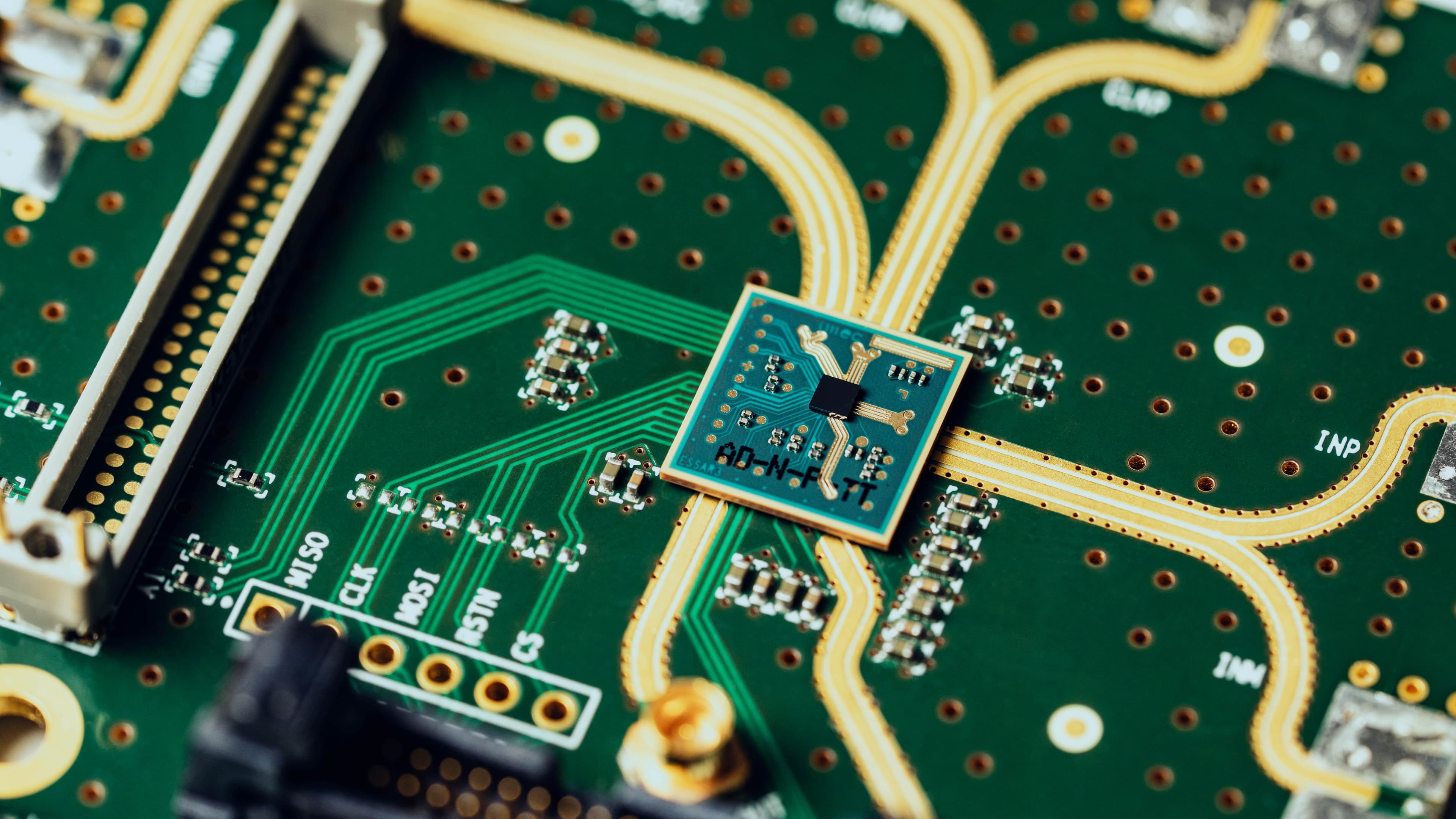

The project introduces a low-cost multi-sensor approach that combines complementary sensing technologies. AID-WELD studies how different sensors relate to each other, and selects combinations that improve defect detection reliability. The sensors will be integrated into a compact, wireless hardware unit that can be mounted on a welding robot and that supports fast data transfer without disrupting existing processes.

In addition, AID-WELD advances real-time machine learning for weld quality monitoring. Current algorithms achieve high accuracy but are not designed for real-time use or for realistic variations in materials and environments. AID-WELD develops efficient models with built-in robustness to noise and geometric variations. The models can adapt to new setups using reference and transfer learning, reducing the need for extensive retraining. The project also automates data interpretation: instead of manual analysis, operators receive clear, human-readable quality feedback.

Finally, AID-WELD plans to validate its approach in real industrial welding environments, linking detection performance to existing quality standards. This makes real-time monitoring both practical and cost-effective for many companies, including SMEs.

Benefits for manufacturing, technology providers, and society.

For industrial users, the project improves weld quality and consistency. Early detection allows operators to intervene during welding instead of after the production. This reduces scrap, rework, and downtime. Productivity gains are another key impact. By reducing offline inspections, production becomes faster and more efficient.

For technology providers, the project creates new opportunities in AI-based monitoring, sensor platforms, and industrial analytics. The modular design researched in AID-WELD will allow for reuse in other manufacturing processes that face similar monitoring challenges.

From a societal perspective, AID-WELD contributes to safer and more reliable industrial products. It also supports sustainability by reducing material waste, energy use, and unnecessary rework.

“By enabling real-time, in-process weld quality monitoring, AID-WELD shifts inspection from a reactive to a proactive approach. It lays the foundation for future self-optimizing welding systems and more resilient manufacturing processes.”

AID-WELD

AID-WELD optimizes robotic arc welding through the use of real-time monitoring and artificial intelligence.

AID-WELD is an imec.icon research project funded by imec and Agentschap Innoveren & Ondernemen (VLAIO).

The project started on 01.01.2026 and is set to run until 31.12.2027.

Project information

Industry

- Bosal Emission Control Systems

- Dekimo

- iba Benelux

- Sanha Fittings

Research

- Belgisch Instituut voor Lastechniek

- imec – IPI – UGent

Contact

- Project lead: Pieter-Jan De Clerck, Sanha Fittings

- Research lead: Brian Booth, imec – IPI – UGent

- Proposal manager: Brian Booth, imec – IPI – UGent

- Innovation manager: Demen Lamon, imec.icon