PVDEBOND

PV module design for recycling by adding "debonding-on-demand" functionality

Why PVDEBOND matters

As global energy demand continues to rise, billions of additional photovoltaic (PV) modules will be installed over the coming decades. To ensure this growth is sustainable, the modules must made so that they can be easily dismantled and efficiently recycled.

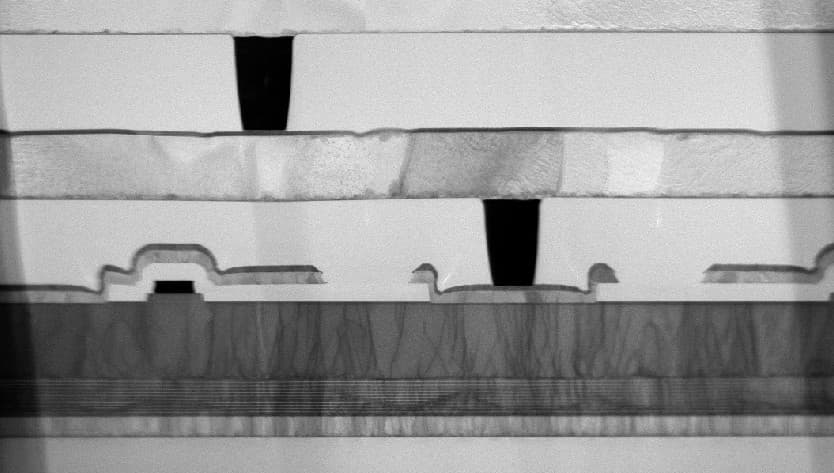

Current recycling methods, such as shredding, often lead to downcycling and the loss of valuable resources like silver. This is largely due to encapsulants engineered to protect solar cells and endure harsh environmental conditions for up to 30 years. But these same encapsulants also hinder the clean separation of components at the module’s end of life.

PVDEBOND offers a sustainable and economically viable alternative by addressing these challenges—maximizing material recovery and minimizing environmental impact. This approach supports a cleaner, more resource-efficient future for the PV industry.

Innovative additives for next-generation recycling

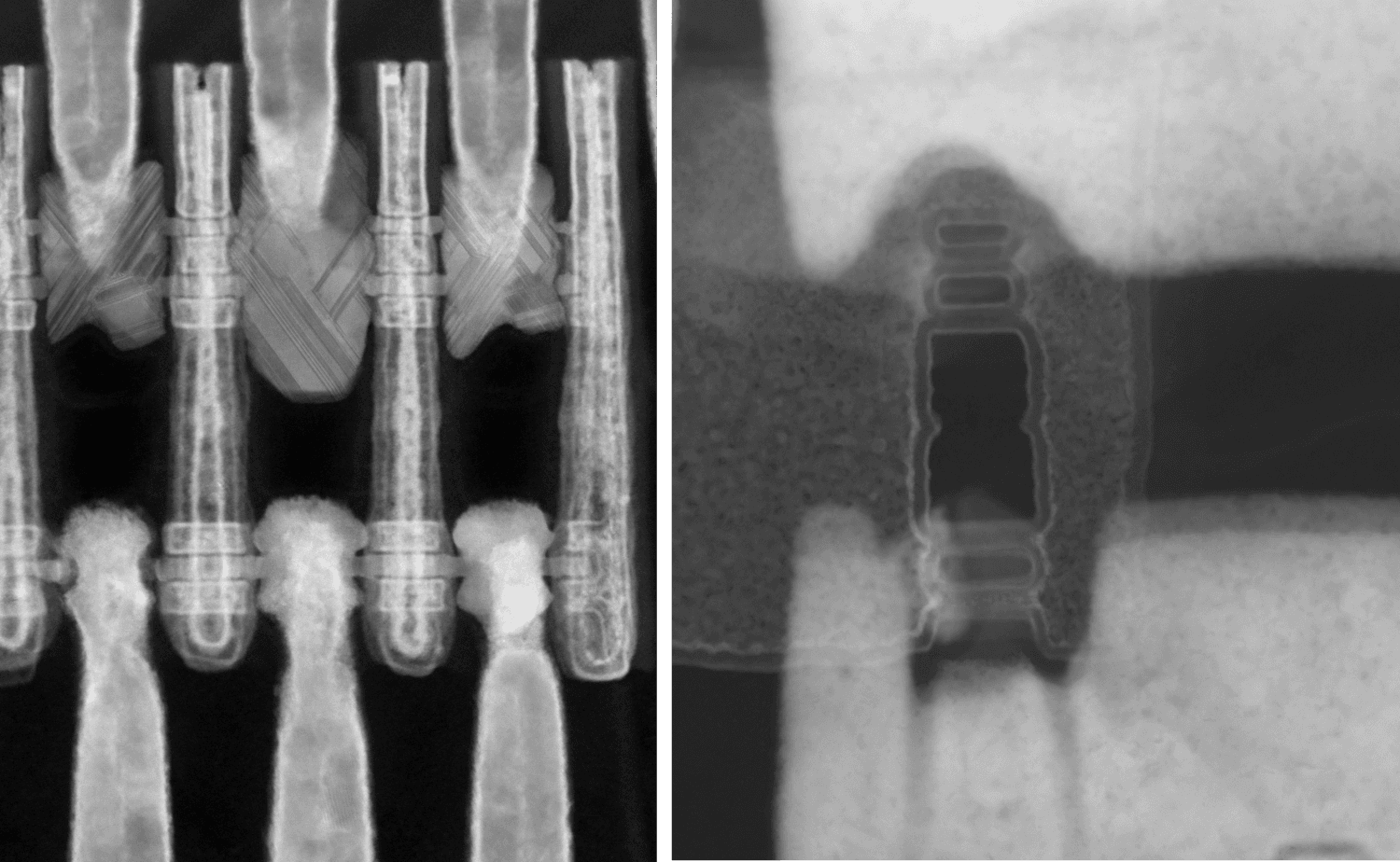

The core goal of the PVDEBOND project is the development of innovative, highly specialized Debonding-on-Demand (DoD) additives. These will either be applied as coatings on the glass cover or back sheet, or be added on/in the encapsulant.

The additives will enable a fast debonding of the different layers in a PV module when a certain debonding trigger is applied. This trigger can be, e.g., infrared or UV illumination, or heat.

These additives should maintain their performance throughout a PV module's 30-year lifespan. They will be designed to:

- Ensure minimal optical and power losses during the lifetime of the PV module.

- Enable clean and residue-free material separation when triggered at the end of life.

- Seamlessly integrate into current PV module production processes.

This innovation paves the way for efficient recycling without compromising the durability or reliability of PV modules, aligning sustainability with industrial practicality.

A strong partnership driving change

This ambitious initiative brings together leading experts in photovoltaics, chemistry, and recycling to tackle complex challenges. From developing irradiation trigger techniques to creating durable additives and scalable debonding tools, PVDEBOND combines advanced R&D with real-world applications to make sustainable PV recycling a reality.

The PVDEBOND project is built on the expertise of a balanced consortium of research and industrial partners, each contributing complementary capabilities across the entire value chain.

“The primary objective of PVDEBOND is to address photovoltaics recycling by designing PV modules specifically for end-of-life separation. This is achieved through debonding-on-demand technology that enables the clean separation of module layers.”

Project information

PVDEBOND

PVDEBOND aims to incorporate debonding-on-demand additives to existing PV encapsulant foils to enable fast, clean, and precise separation and recycling of materials.

PVDEBOND is an imec.icon research project funded by imec and Agentschap Innoveren & Ondernemen (VLAIO).

The project started on 01.12.2024 and is set to run until 30.11.2027.

Industry

- Becquerel Institute

- Galloo

- IP FAB

- Soltech

Research

- Analytical & Circular Chemistry (ACC) – UHasselt

- imec – IMO-IMOMEC – UHasselt

Contact

- Project lead: Kristof Proost (IP FAB)

- Research lead: Arvid van der Heide (imec – IMO-IMOMEC – UHasselt)

- Proposal manager: Arvid van der Heide (imec – IMO-IMOMEC – UHasselt)

- Innovation manager: Annelies Vandamme