Imaging technology development

Leverage imec’s longstanding expertise to develop image sensors with specifications outside those of commercial sensors.

Imec’s specialty image sensors are based on CMOS image technology and tuned to meet exceptional specifications such as extreme speeds or ultra-low noise.

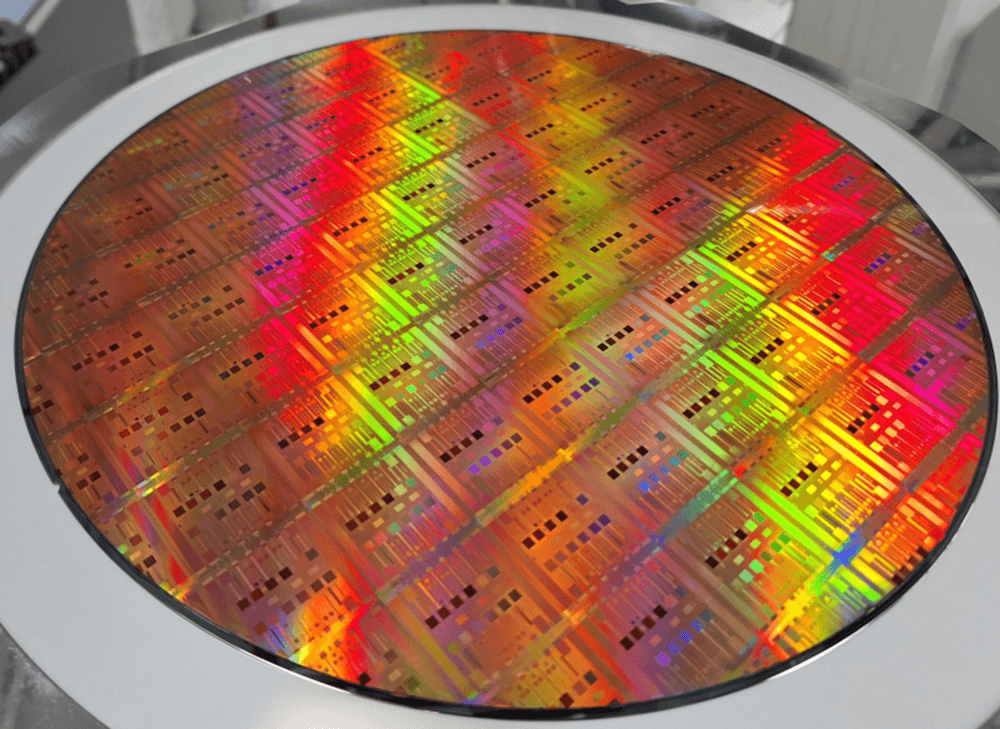

By combining this expertise with our heterogeneous integration processing platform, we can help you to develop and implement your ideas and concepts into a microsystem product. Prototyping and low-volume manufacturing of your dedicated high-end CMOS imagers and vision systems is achieved in-house on 200 and 300mm wafers. If needed, we can transfer the manufacturing process to a high-volume foundry.

Imaging technology expertise

Imec’s imager activities are based on a 130nm CMOS process technology on 200mm silicon wafers, including a dual-gate module and MiM capacitors. Our baseline platform is extended with a number of imager-specific process modules:

- special epitaxial silicon wafers

- stitching for large area imagers

- CCD-in-CMOS process to combine the best of high-speed, low-power CMOS read-out circuitry with lowest noise, highest QE charge transfer domain CCD pixel technologies

- backside illumination with custom (ARC) anti-reflection coatings for maximal QE performance with possibility for tuning photon collection in UV, visible to NIR (near-infrared) wavelength range

- pixel-level Fresnel lenses

- hyperspectral filters

- organic photodiodes

Explore our imaging, sensing and actuation expertise

Tailored solution

We customize your imager according to your specifications, from design and development up to low volume manufacturing.

Choose up to which level you want to engage with imec:

- Design and develop your custom imager with imec, both at pixel and at imager system-on-chip level, including:

- fast and power-efficient column analog-to-digital convertors

- full imager architectural design including digital I/O

- Develop your custom imager including integrated filters:

- addition of 7 spectral filters to enable multispectral TDI

- post-processing of spectral filters on the wafer or on the glass lid

- Obtain ceramic-packaged imagers.

Monolithic thin-film image sensor for the SWIR range

Examples of our imaging technology capabilities

CCD-in-CMOS for time delay integration (TDI) imaging

Imec’s CCD-embedded TDI CMOS image sensors combine the high level of integration and power efficiency of CMOS technology with low-noise, high-speed, spectrally-flexible CCD technology. Our CCD-in-CMOS technology combines single poly CCD photogates into a standard 130nm CMOS.

This technology is ideal for imaging scenes that move in a linear way:

- satellite-based earth observation

- drone-based earth observation

- industrial inspection

Ultra-high-speed imaging

Imec pushes the limits of fast imaging by maximizing the achievable frame rate. We realize this by leveraging a combination of:

- dedicated epitaxial silicon wafers

- backside illumination including backside bias

- state-of-the-art CMOS mixed analog/digital design

Backside-illuminated CMOS imagers feature very high intrinsic light sensitivity and are extremely efficient in detecting (near) ultraviolet and blue light.

Imec and Pharshighted: capturing reality at 326,000 frames per second

Lens-free microscope

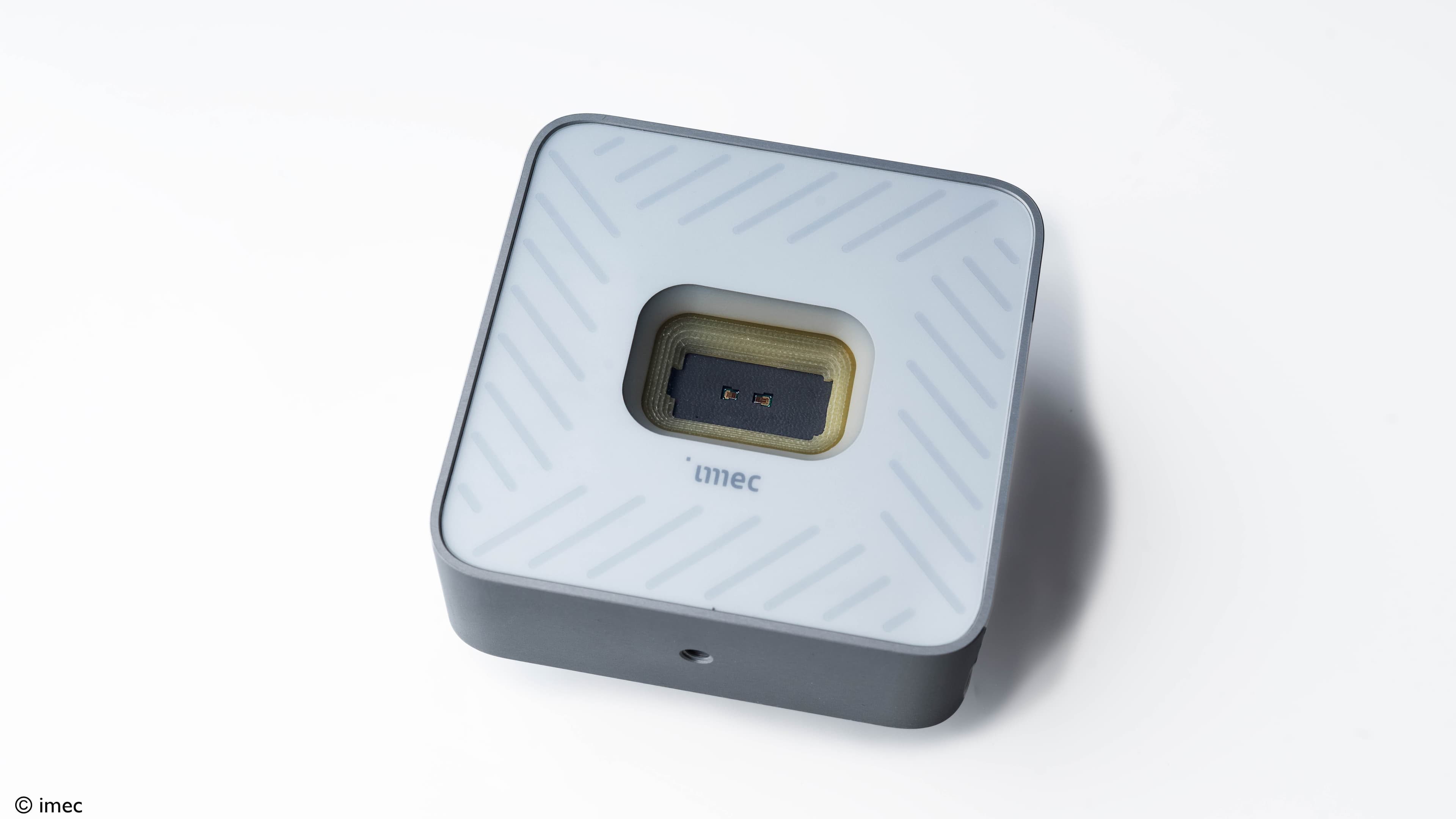

Imec’s on-chip lens-free microscope offers large-field-of-view live imaging at micrometer resolution. It can be integrated into life sciences and biotech tools, targeting multiple applications such as label-free cell monitoring, automated cell culturing, or automated high-throughput microscopy.

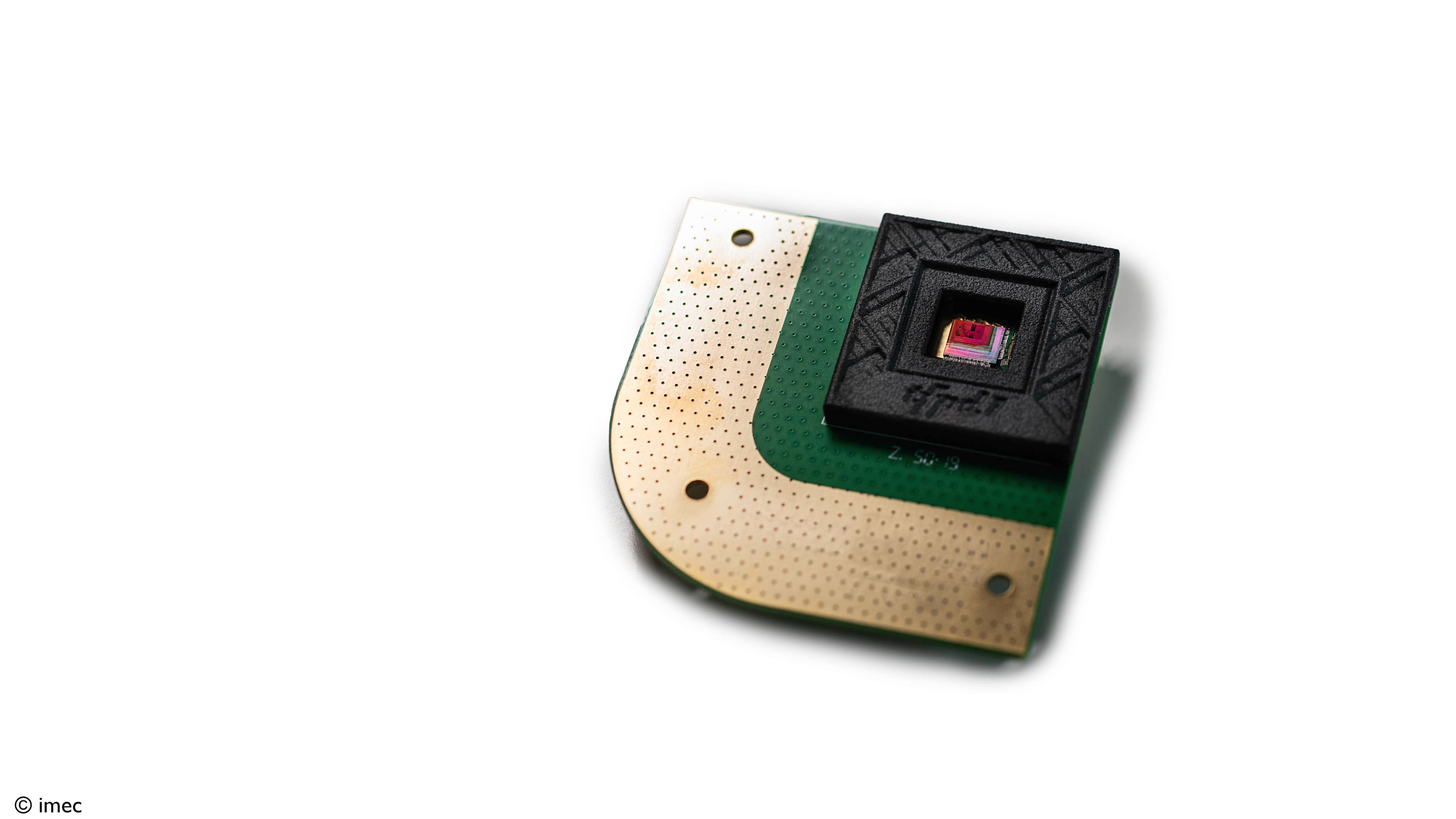

Hyperspectral imaging

Imec has developed a process for depositing hyperspectral filters directly on top of CMOS image sensors at wafer level. The combination of the production of filters and sensors in one CMOS-compatible flow, leads to an overall simplification and cost reduction, and enables mass production.

The imec snapscan VNIR camera, with an integrated imec hyperspectral sensor.

Imaging technology prototypes

We’ve developed several prototypes of TDI imagers using our CCD-in-CMOS technology:

Analog output TDI imagers

|

Spec |

Value |

|

Array size |

512 stages x 1024 columns |

|

Pixel size |

5µm |

|

Stage selection |

8 or 512 |

|

Full well |

18ke- |

|

Noise |

20e- |

|

Conversion gain |

25µV/e- |

|

Dark current |

3nA/cm2 |

|

CTE |

>99.995 at 400kHz |

|

Supply voltages |

3.3V, 1.2V and -1.5V |

Digital output TDI imagers

|

Spec Target |

Value |

|

Array size |

4k x 256 per band |

|

Pixel size |

5.4µm |

|

Stage selection |

1-to-256 per band individually |

|

Bi-directional |

Yes |

|

Number of bands |

1 band or 7 bands #bands can be enabled |

|

Line rate |

Up to 300kHz aggregate (e.g. 57kHz per band when all bands enabled) |

|

Power |

<5W |

|

Dynamic range |

>60dB – 40dB |

|

CTE |

>0.99995 at >300kHz |

|

QE |

>90% VIS /wo color filters >60% UV |

|

Package type |

Ceramic µPGA |

|

Output type |

32x 1Gb/s LVDS |

|

Color filters |

On glass lid or on the sensor |

Multispectral TDI imager

We have developed a color or multispectral TDI imager based on our 7-band digital TDI. This is particularly interesting for airborne remote sensing, satellite imagery, life sciences instrumentation and machine vision applications.

Want to tap into out expertise and infrastructure to develop your dedicated image sensor?