ClaXon

Improving the interaction between people and collaborative robots in factories

For safety reasons, robots in a manufacturing environment are typically shielded from humans. However, humans and robots have very complementary skills. Combining the dexterity, flexibility and problem-solving ability of humans with the strength, endurance and precision of robots, the quality of industrial production can be improved – as well as people’s working conditions.

Yet, introducing so-called ‘cobots’ (collaborative robots) to flexibly assist human personnel in a range of tasks faces several technological and acceptance hurdles.

“We explored how uncaged cobots can more effectively be used in factories,” explains An Jacobs (imec - VUB). “One challenge we looked into, was how to make cobots sufficiently robust for use in manufacturing settings – leveraging for instance multimodal sensor input and vision technology to enhance human-machine interaction in noisy environments. Secondly, we investigated the human side of the equation: how do machine operators want to interact with robots? And how do they expect robots to help them with their daily operations?”

Project outcomes

- New adaptive control software that increases flexible robots’ accuracy by 60%

- Novel ways to tell a robot what it needs to do – using multimodal sensor input, and based on extensive living lab user research

- Putting the ClaXon learnings into practice at Audi Brussels

ClaXon

Improving the interaction between people and collaborative robots in factories.

ClaXon is an imec.icon research project funded by imec, IWT and Innoviris.

It ran from 01.01.2015 until 31.12.2016.

Project information

Industry

- Robovision

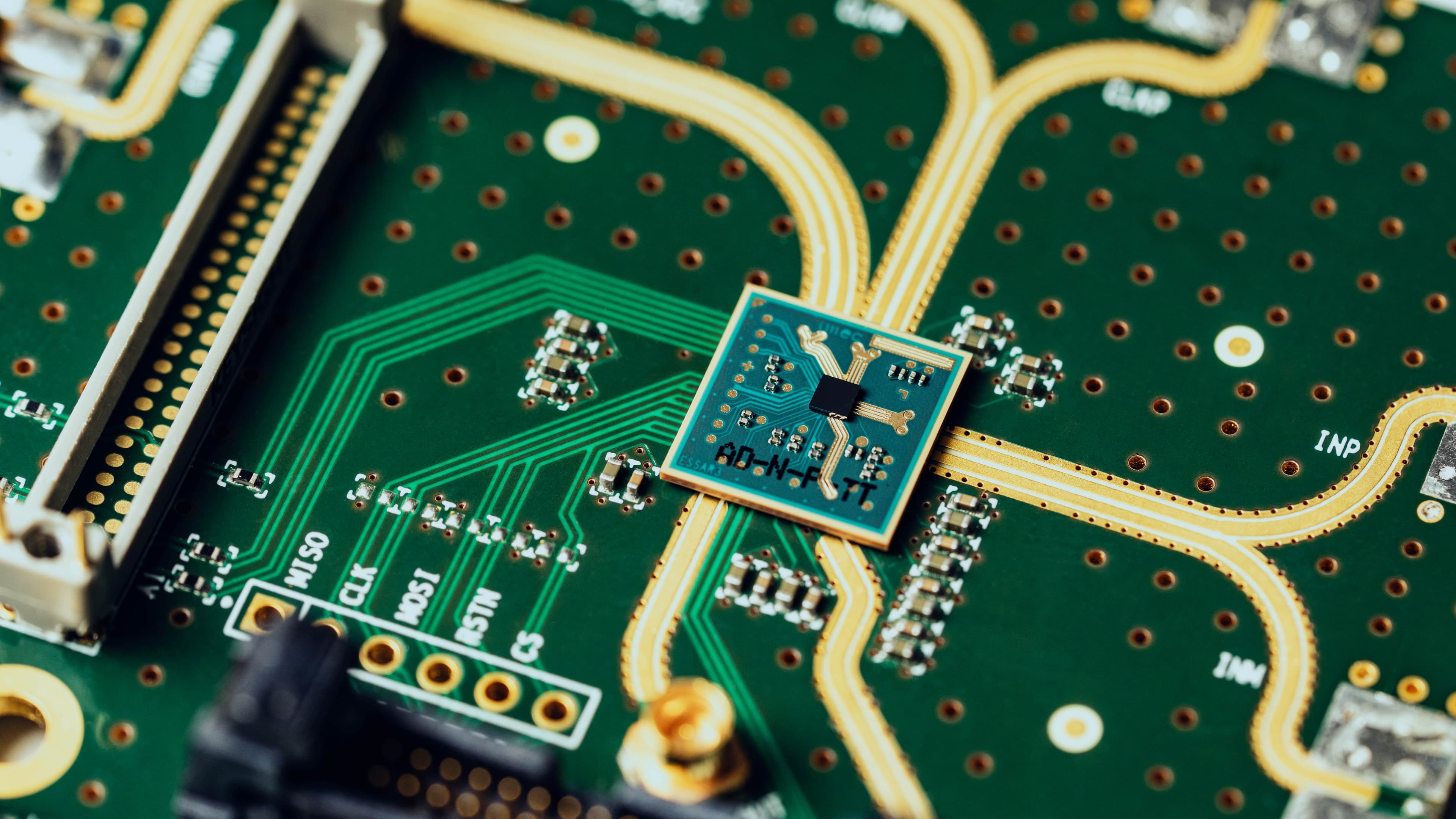

- Melexis Technologies

- AMS

- Audi Brussels

- SoftKinetic sensors

- SoftKinetic software

- Robotics and MultiBody Mechanics Research Group

Research

- imec - EDM-IT - UHasselt

- imec - SMIT - VUB

- VUB - R&MM

Contact

- Project Lead: Ilse Ravyse

- Research Lead: An Jacobs

- Innovation Manager: Piet Verhoeve