From off-the-shelf components to custom silicon

Today’s semiconductor technologies make it possible to integrate optical, mechanical, and electrical functionalities into a single product. While much attention is typically placed on deciding which functionalities to include, an equally critical decision lies in how they are implemented.

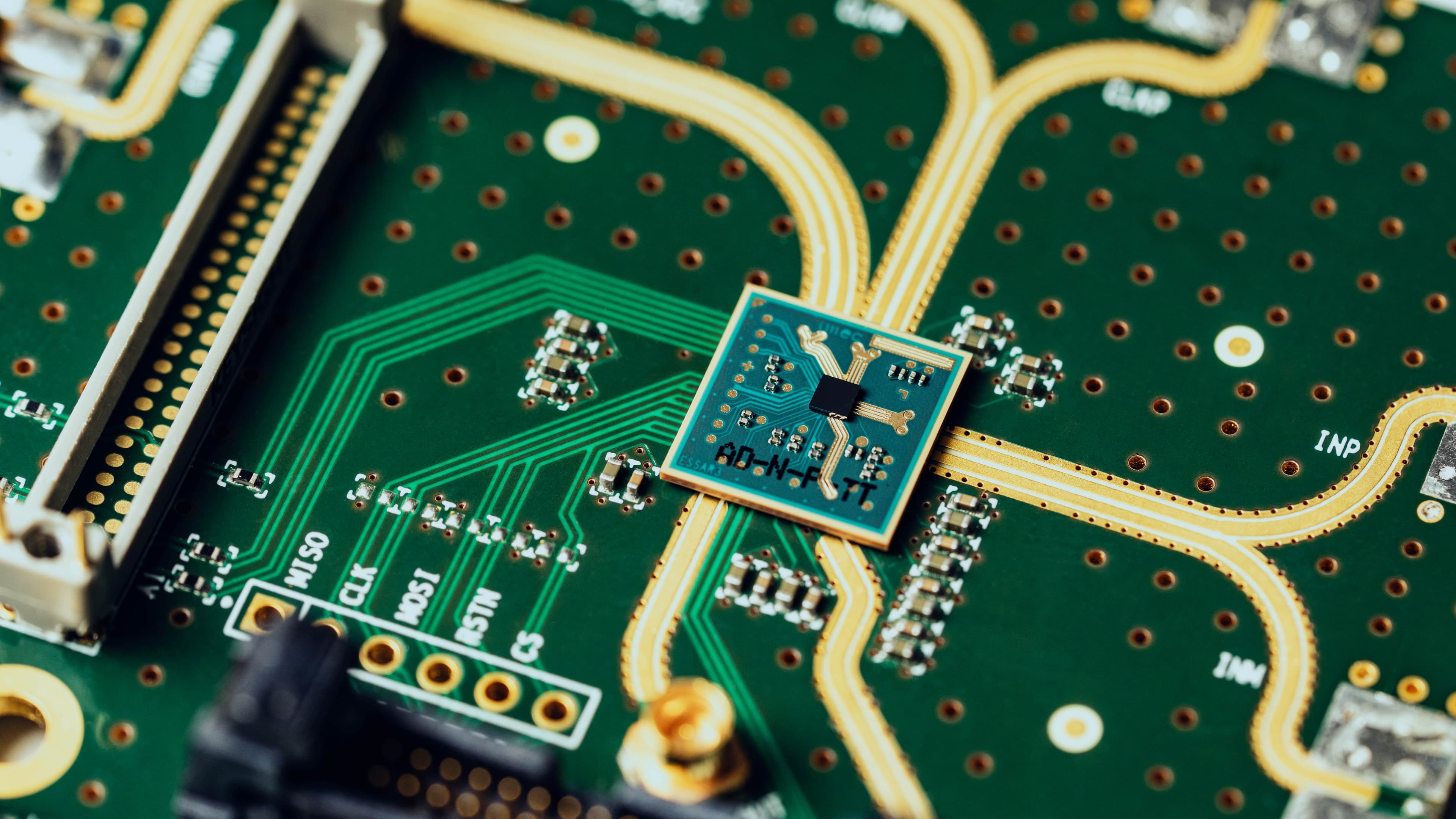

Product developers generally face two implementation paths. The first relies on a printed circuit board (PCB) with off-the-shelf components such as processors, imagers, and wireless transceivers. The second option is a fully customized solution in the form of an application-specific integrated circuit (ASIC).

Standard components offer clear advantages: lower upfront development costs, high flexibility, and a fast time to market. However, they often fall short when it comes to performance optimization, power efficiency, and compact system design.

ASICs, by contrast, are purpose-built for a specific function or application. By tailoring the silicon to exact requirements, ASICs can deliver superior performance, reduced power consumption, and a significantly smaller form factor – unlocking new levels of product differentiation.

The strategic advantage of custom silicon or ASICs

Choosing an ASIC-based approach delivers a set of tightly interconnected advantages that extend well beyond silicon integration alone. Together, these benefits can significantly enhance product performance, differentiation, and long-term competitiveness. The most important advantages include:

1. Cost efficiency at scale

ASIC development involves substantial upfront investment, primarily in non-recurring engineering (NRE) costs. However, as production volumes increase, the cost per unit decreases dramatically. In addition, ASIC-based solutions can reduce expenses related to inventory management, product maintenance, thermal management, and shipping.

2. Compact system design

ASICs consolidate multiple functions into a single chip through monolithic integration or system-in-package (SiP) approaches. This high level of integration enables significantly smaller form factors, which is especially critical for space-constrained applications such as mobile and wearable devices.

3. Low power consumption

By integrating multiple functions on a single chip, ASICs minimize energy losses associated with interconnects and reduce the overall power required to operate the system. This power efficiency is closely linked to compactness and is a key enabler for battery-powered mobile applications.

4. High performance

Because an ASIC is purpose-built for a specific application, it can execute its intended function with maximum performance at the lowest possible energy cost. Shorter signal paths, optimized architectures, and tailored power management contribute to superior speed and efficiency compared to general-purpose solutions.

5. Intellectual property protection

An ASIC provides a strong barrier against product imitation. By embedding critical functionality directly into custom silicon, it becomes significantly more difficult for competitors to copy or reverse-engineer the solution, strengthening long-term competitive advantage.

6. Supply chain control and consistency

Standard designs rely on multiple discrete components sourced from different suppliers, increasing exposure to availability and lifecycle risks. An ASIC simplifies the supply chain, improves control over component availability, and ensures consistent performance and characteristics across the entire product portfolio.

The ASIC journey explained

Designing an ASIC is a complex but highly rewarding process, transforming product ideas into custom silicon solutions. In short, these are the different steps that you and your ASIC partner will follow:

- Understanding the product’s requirements and determining if an ASIC is the right approach for performance, cost, and time-to-market.

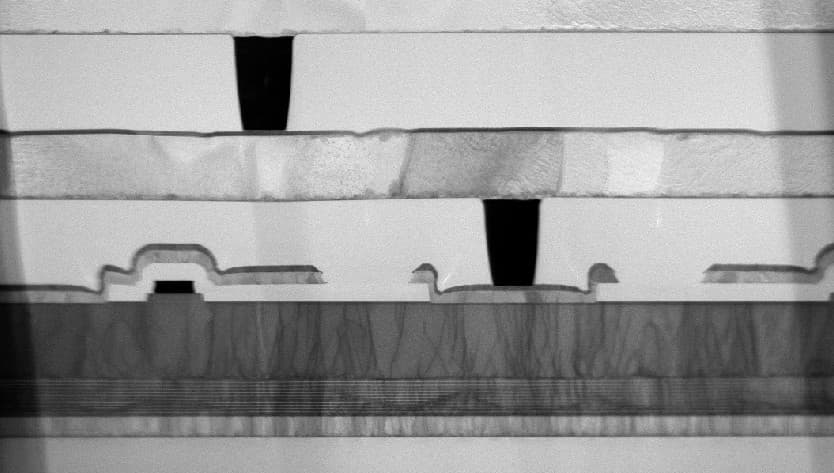

- Translating system requirements into detailed chip specifications, balancing functionality, power efficiency, and cost.

- In the design phase, defining the architecture of digital and analog circuits – checking which pre-designed IP can be used to accelerate development.

- Executing verification and testing plans to ensure the chip performs exactly as intended before it moves to production.

- Designing the package in parallel with the chip, ensuring reliability, connectivity, and a compact form factor.

- Translating the design into manufacturing steps, using advanced technology nodes and precision manufacturing processes.

- Assembling the packaged chips into products, connecting them with other components.

- Testing the functionality and the production, ensuring the chip operates correctly and can be reliably produced at scale.

- Finally, successful qualification leading to mass production, supported by efficient supply chain management to meet market demand.

Custom ASIC flow

End-to-end support for your custom ASIC development

Imec launched IC-Link as its dedicated chip manufacturing division to bridge the gap between advanced research and market-ready products. IC-Link provides end-to-end support across the entire ASIC lifecycle, offering tailored solutions that help companies successfully move from concept to production while ensuring high-quality, reliable custom ASICs.

Here's a snapshot of why companies contact IC-Link for ASIC solutions:

| Question / situation | How IC-Link can help |

| Obsolete PCB component | Control supply chain, add unique functionalities, optimize from design phase |

| Need specific technology / packaging | Access to multiple options, advice on best fit for product |

| Planning high-volume production | Reduce unit cost, improve ROI, example: 7nm processor ASIC |

| Entering new market | Smaller, reliable, easier-to-test solutions |

| Designing first prototype | Plan ahead for ASIC transition, save cost and complexity later |

The following stories highlight real-world ASICs developed by IC-Link, showcasing how our end-to-end solutions have helped clients across industries bring their custom chips from concept to production.

Click the picture to discover the story behind the product.

Curious about ASICs? Our comprehensive white paper, ‘ASICs – The benefits and how to seize them,’ is available for free download.

Published on:

28 January 2026