Imec school prepares candidates for a job in the cleanroom

On 1 September 2019 imec school opens its doors for the next-generation of cleanroom technicians. Candidates will receive a tailored training — partly in the class room and partly on the job — to learn the necessary process techniques and technical skills. A technical degree or experience is not a must, only a strong dose of motivation and a passion for technics. In 8 to 12 months, imec school prepares applicants for a job as a first-line technician, responsible for the first-line support of operational, technical, process and hardware issues with the machines in the imec cleanrooms. In keeping the machines operational, they enable researchers to make prototypes of the newest technologies that will improve our lives.

Do you know somebody who might be interested? Visit the website for more information about the initiative.

Whole genome sequencing becomes an affordable reality for patients

On international DNA day (April 25), imec and its partners in the GAP imec.icon project revealed their Genome Analytics Platform (GAP) platform, a unique platform that can perform a full genome analysis of 48 samples in only 48 hours and at an acceptable cost. The GAP-platform enables the widespread clinical use of whole genome sequencing. Since the 1,000-dollar genome is almost a reality, turning the raw sequencing data into ‘knowledge’ and useful information for doctors has become the economic bottleneck. Researchers and industry leaders in the GAP-project have now tackled this challenge by developing a new genomic analytics platform that bridges the gap between the low cost of sequencing and the high cost of analyzing raw sequencing data. It enables not only researchers, but also doctors, to analyze and compare genome data for diagnosis, prognosis, or treatment selection.

More information about the imec.icon-project can be found here.

Read the full press release here.

On a ‘Smart Highway’ cars collaborate to avoid accidents

Last month, the new Smart Highway infrastructure, a permanent test site along the E313 / E34, was put to the test in a simulation of a real-life situation with two connected, collaborating cars. On the roof of both cars, researchers from imec, UAntwerp and UGhent, installed a radio module for communicating with other cars and the road infrastructure. At the same time, radio units were spread out at the side of the road across the circuit to communicate with the cars. During the test of 8 April, the first car had to make an emergency stop, while the second car immediately received a warning to brake or stop. The information was exchanged rapidly ¬—even with a non-equipped car driving in between. The goal of the project is to improve road safety and provide self-driving cars in the future with an extra source of information. Smart Highway runs in parallel with the European CONCORDA project.

Read all about the successful test in the press release (Dutch only).

For more information, read the imec magazine article.

Test car with radio module.

Test car with radio module.

Successful Partner Technical Week

Last month, we’ve enjoyed a very busy and interactive partner technical week (PTW) at the imec Leuven site. Twice a year imec invites its partners to discuss the most recent results. At the latest edition, no less than 721 members of our partner companies attended the technical sessions. The numerous highlights that were presented clearly show the great teamwork between the design, integration, unit process, fab and logistic teams in imec. The next PTW will take place between 21 and 25 October 2019.

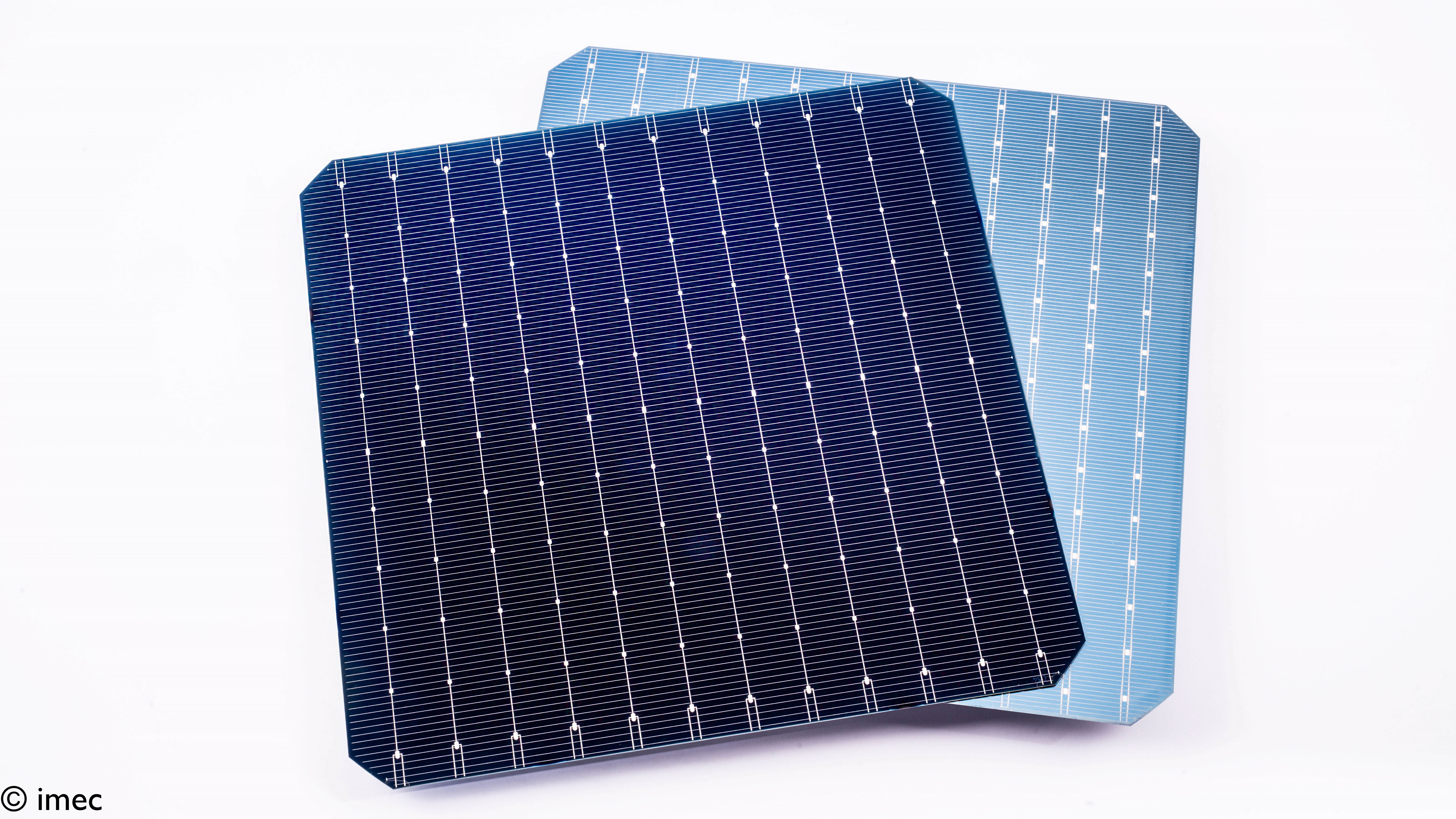

Record conversion efficiency of 23.2% with bifacial n-PERT solar cells

Imec’s n-PERT (Passivated Emitter and Rear Totally diffused) solar cells developed within the EnergyVille collaboration together with Jolywood, a leading Chinese manufacturer of n-type bifacial solar cells and modules, have reached a certified front-side conversion efficiency of 23.2 percent. The open circuit voltage (Voc) is now above 690mV with fill factors up to 83%. These remarkable results are obtained using the same industry-compatible equipment to produce bifacial p-PERC cells, with the addition of a boron diffusion. The developed n-PERT technology has a number of inherent advantages over p-type PERC cell technology, which is demonstrated in these newest cells: the potential for higher efficiencies because of a lower sensitivity to metal impurities, and the absence of light induced degradation. With cost-efficient processing and a clear path to higher efficiencies, this makes these n-PERT cells a serious contender to p-PERC technology.

Read the full press release here.

Imec's bifacial solar cells.

Imec's bifacial solar cells.

Published on:

8 May 2019