Custom electronic component development for space

Custom, space-grade electronic components for satellite payloads.

With giants like ESA and NASA, space exploration was long associated with large-scale scientific missions. Over the past decade, however, satellites have transformed space into a thriving commercial frontier – powering Earth observation, global broadband communications, and unlocking new opportunities for innovation and business.

The New Space era

Satellite payloads – such as communication systems, sensors, navigation tools, scientific instruments, and environmental monitoring equipment – are the core functional elements of any space mission.

Traditionally developed by specialized subcontractors, these components are now part of a rapidly evolving space ecosystem. In the era of ‘New Space’, a new generation of satellite builders is emerging, driving demand for more flexible, innovative, and custom-designed payload components.

The sector faces several challenges, both technical and strategic:

- Miniaturization: payloads need to be smaller, lighter, and more power-efficient to fit on compact satellites – especially in constellations – while still delivering high performance. Achieving this without sacrificing sensitivity, resolution, or robustness is a major engineering challenge.

- Harsh space environment: payloads must operate reliably in extreme conditions – radiation, temperature fluctuations, vacuum, and mechanical shocks during launch. Ensuring long-term durability and performance in these environments requires advanced materials and rigorous design and testing.

- Customization and flexibility: with more diverse missions and commercial applications, there’s growing demand for tailor-made payloads. Developers must balance customization with cost-efficiency and scalability, especially for low-volume production.

- Faster development cycles: new space companies often work with shorter timelines than traditional space agencies. Payload developers must adapt to faster design, prototyping, and qualification cycles – without compromising reliability.

- Data handling and processing: as payloads become more advanced (e.g. high-res imaging, hyperspectral sensors), they generate massive amounts of data. Efficient onboard processing, compression, and transmission are critical to mission success. Increasingly, AI-powered algorithms are being deployed to enable real-time data filtering, anomaly detection, and autonomous decision-making, reducing the need for ground intervention and optimizing bandwidth usage.

Advanced technologies for custom satellite payloads

Imec offers cutting-edge technologies to help satellite builders develop custom payload components that cannot be sourced from traditional foundries or engineering houses.

From early-stage innovation to flight-ready hardware, imec supports dedicated development-on-demand projects tailored to your specifications.

Our expertise includes integrated imagers, radiation-hardened circuits, optical transceivers, and efficient power conversion systems – designed to operate reliably in the harsh conditions of space. As satellites become smaller and more capable, imec leads in scaling technologies while enhancing performance.

Imec also brings extensive experience in space evaluation and qualification (ESCC2269000 and ESCC9000), including the development of custom test hardware and full supply chain management for flight module screening.

DARE: Radiation-hardened design for space

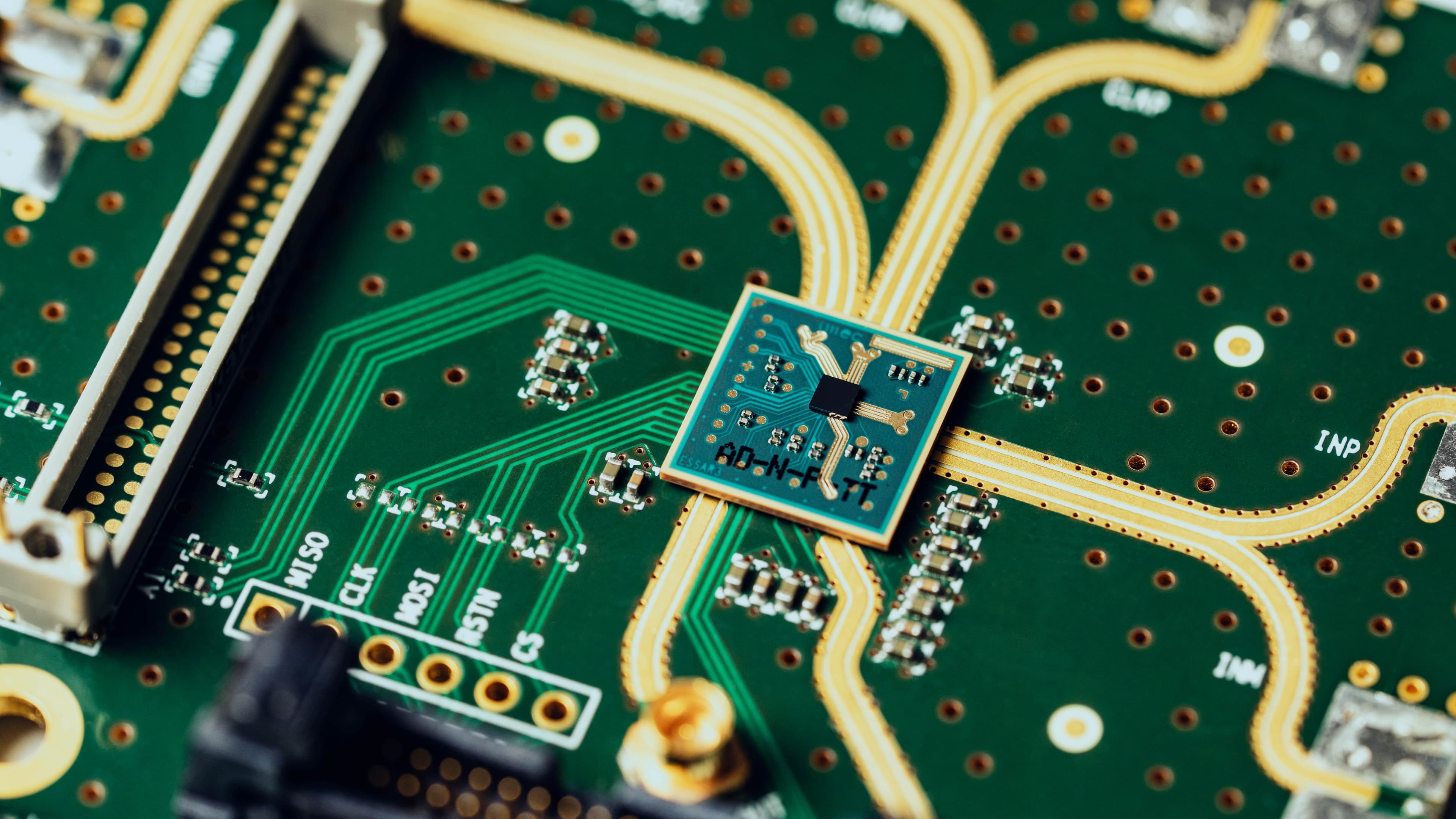

Imec’s DARE platform, developed with ESA, enables the integration of custom digital and analog blocks into radiation-hardened chips for space applications. It includes digital cell libraries, analog design support, and reusable IP blocks, guiding the full flow from design to flight-ready models.

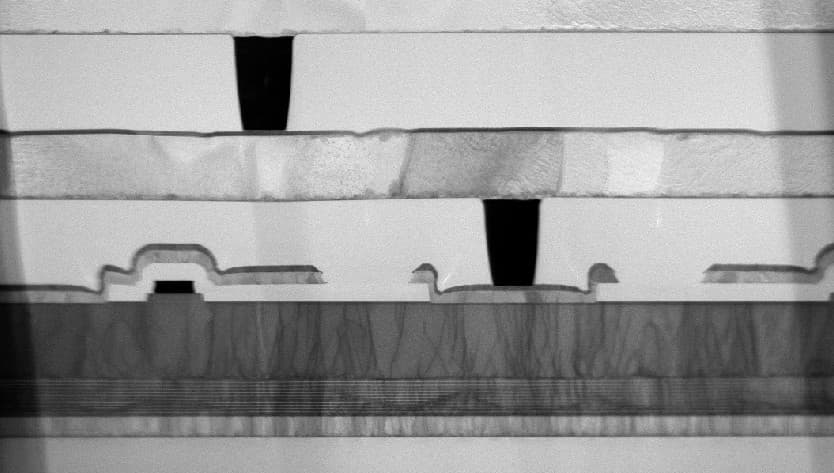

DARE supports advanced CMOS technologies, now including 22nm and 7nm, with proven techniques to mitigate radiation effects. Analog designers benefit from imec’s Cadence Analog Design Kit, and digital designs use adapted place-and-route methods to counter single event effects.

Satellites face limits in transmitting raw data. AI is key to onboard processing – filtering and prioritizing data before sending it to Earth. Imec is exploring ultra-deep submicron technologies to embed intelligence into payloads, enabling autonomous decision-making and efficient data handling.

Read about the shared journey of Frontgrade Gaisler and IC-Link

180nm mixed-signal rad-hard ASIC

Custom imager development

Imec offers a platform to co-develop specialty imagers tailored to your mission needs – from design and prototyping to volume manufacturing.

- Custom imagers: designed and developed to your specifications, including high ground resolution and spectral filtering (multi/hyperspectral).

- Hyperspectral detectors: for earth observation from small satellites and for space exploration, including directly deposited filter-on-chip solutions for high signal-to-noise ratio.

- Ultra-high-speed imaging: essential for studying fast phenomena in space and science, imec develops fast pixels and readout electronics. Read a testimony from Pharsighted.

- Flat optics: compact lenses and filters for miniaturized imaging systems.

- Infrared sensors: R&D in quantum dot-based IR detection

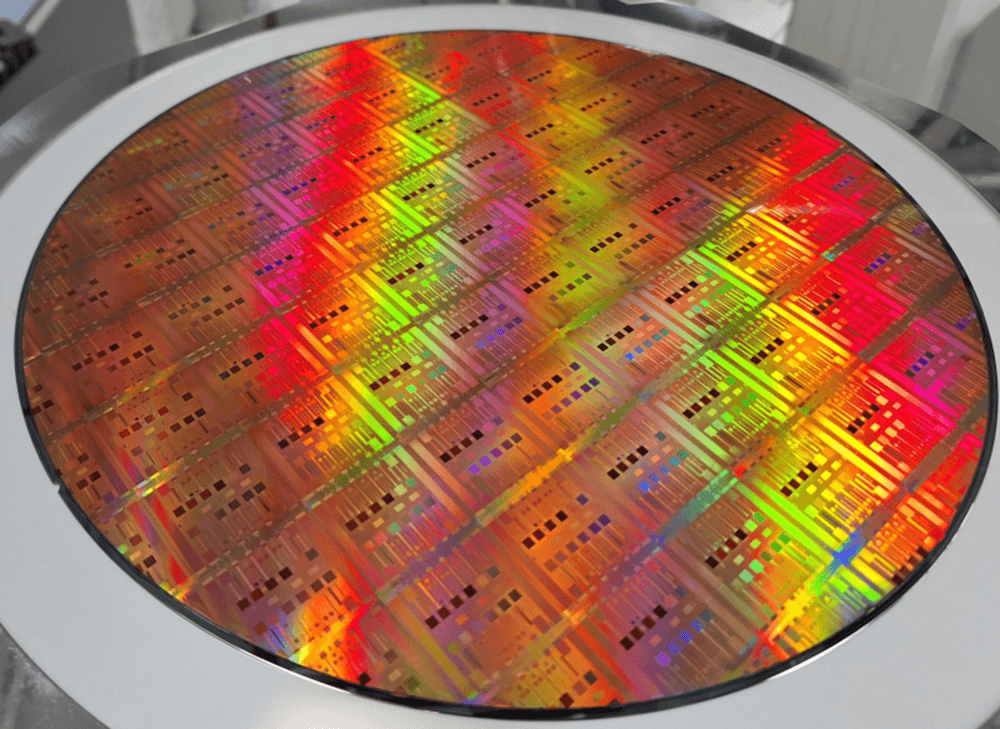

- Microbump technology: ultra-small microbumps on 300mm wafers to connect electronics with pixels.

Left: CMOS imager with ultra-light-sensitivity and -high-speed characteristics, developed for Pharsighted; Right: 96-band hyperspectral imaging sensor for earth observation.

Radiation-hardened power electronics for satellites

Efficient DC/DC and point-of-load converters are essential for stable power delivery in space systems. Imec supports the development of compact, integrated, and radiation-hardened power components based on GaN-on-Si technology, from concept to testing and qualification.

- GaN-on-Si transistors with state-of-the-art electrical performance.

- E-mode power devices proven to resist degradation after heavy ion and neutron irradiation.

- Monolithically integrated circuits for compact and efficient power management.

Monolithic integrated symmetrical half-bridge with integrated drivers, temperature and current sensors.

Optical communication for space

Optical links offer higher speed, bandwidth, and lower interference than traditional RF. Imec’s integrated photonics platform enables compact, low-power, and ultra-reliable optical transceivers – ideal for intra-satellite, satellite-to-satellite and satellite-to-Earth links. The hybrid optical beamforming platform supports non-mechanical beamforming, ready for harsh space environments.

Imec’s state-of-the-art 4x56 Gb/s rad-hard modulator driver IC.

Non-Terrestrial Networks (NTN)

Imec is at the forefront of next-generation connectivity, delivering cutting-edge solutions for both terrestrial and non-terrestrial networks (NTN). Leveraging decades of semiconductor innovation, imec combines advanced RF technologies, ultra-low-power wireless circuits, and high-speed wireline transceivers to enable seamless communication from the ground to space.

Imec’s NTN expertise spans:

- Satellite communication

- Positioning technology

- Timing systems

- GaN-on-silicon process technology and devices for power amplifiers, high-efficiency front-end modules, and integrated system design for 5G, 6G, and beyond.

R&D on the systems and circuit side includes digital beamforming technology, which allows highly flexible, software-defined control of antenna arrays for precise beam steering and dynamic link optimization.

This capability enhances coverage, improves spectral efficiency, and supports massive MIMO architectures critical for future NTN deployments.

Through state-of-the-art infrastructure and a global ecosystem of partners, imec accelerates innovation, reduces time-to-market, and empowers industries to unlock new opportunities in connectivity.

Work with us to develop your radiation-hardened electronics

Let’s explore how imec can support you at every stage of designing and fabricating radiation-hardened electronics.

Discover our broad portfolio of advanced technologies for next-generation satellites, our role as your R&D partner for co-development and customization, and how we can assist with volume manufacturing.

Click the contact button below to set up a meeting.